Strong reflective type pavement marking coating preparation device and technology

A technology for road markings and preparation devices, which is applied in the field of coatings, can solve problems such as poor reflective effect of road surfaces, severe surface wear, and loss of efficacy of reflective particles, and achieve timely mixing, quality improvement, and high effectiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

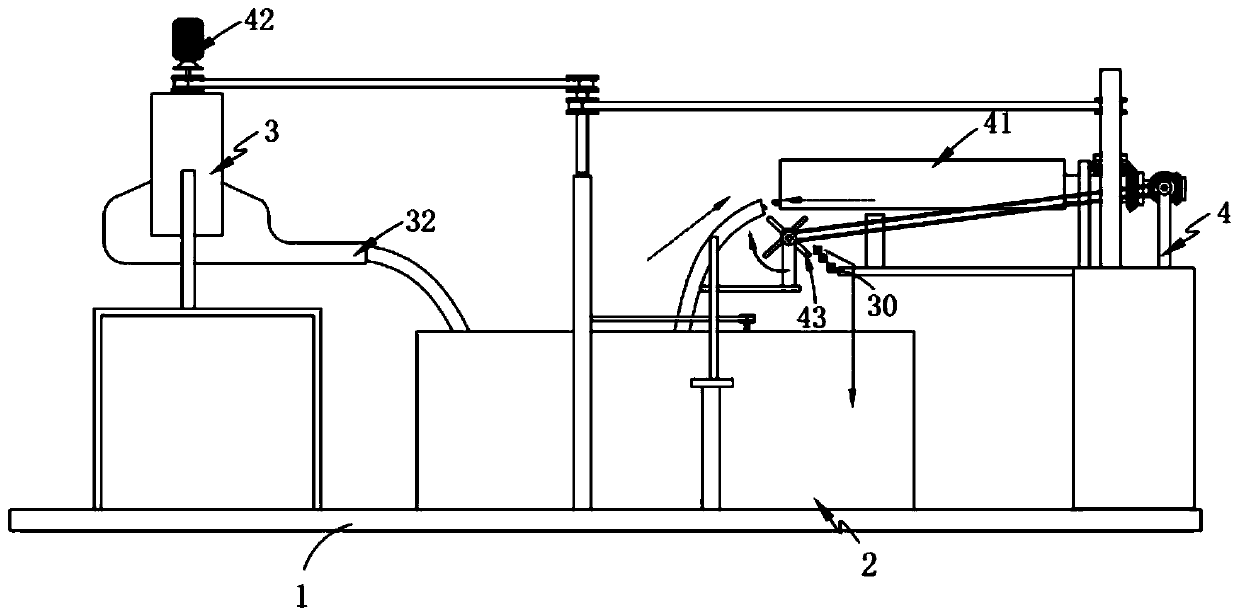

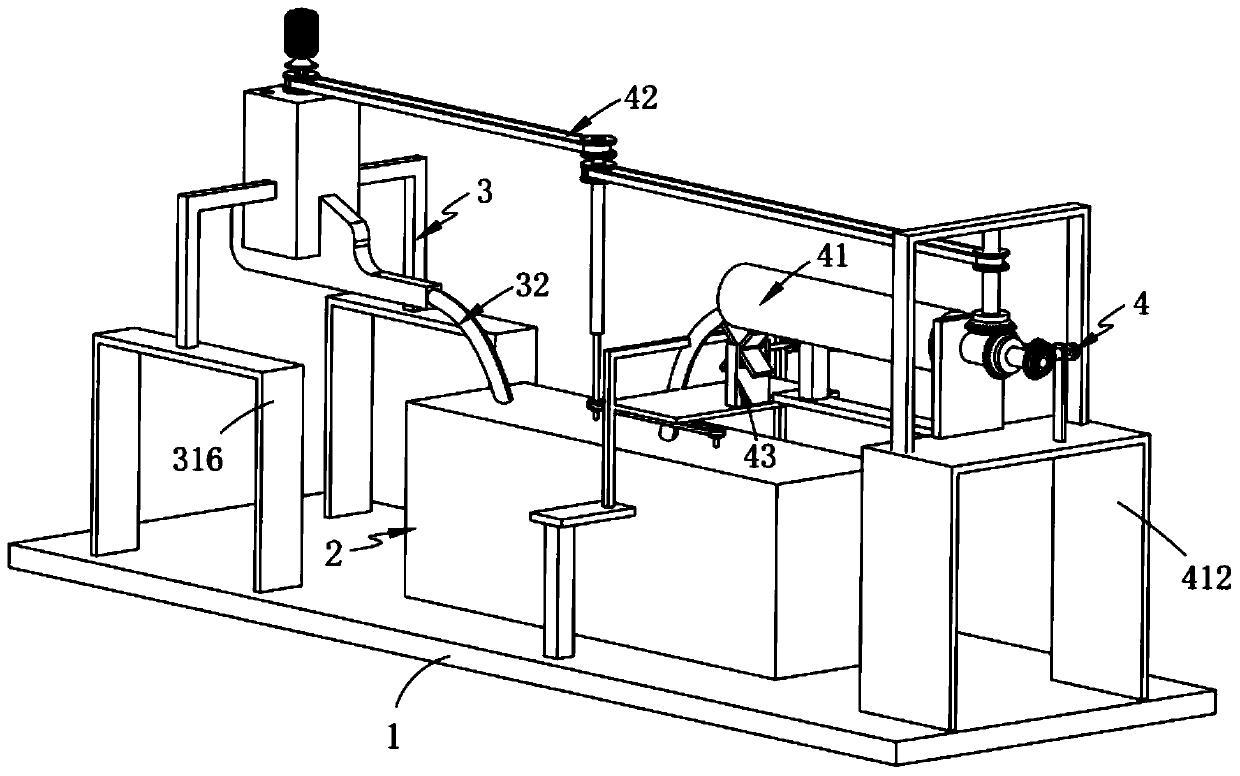

[0087] like figure 1 , figure 2 As shown, a preparation device for strong reflective pavement marking paint, comprising:

[0088] workbench 1;

[0089] The screening mechanism 2, the screening mechanism 2 is installed on the workbench 1 and is centrally arranged;

[0090] Particle discharging mechanism 3, the particle discharging mechanism 3 includes a grinding assembly 31 and a grinding assembly 31 arranged on one side of the screening mechanism 2 along the length direction of the worktable 1 and arranged in linkage with the screening mechanism 2. The grinding assembly 31 is communicated with the jet assembly 32 disposed through the screening mechanism 2; and

[0091] Resin discharge mechanism 4, the resin discharge mechanism 4 includes an extrusion assembly 41 arranged on the other side of the screening mechanism 2 relative to the particle discharge mechanism 3, and is arranged in linkage with the grinding assembly 31 and is connected with the particle discharge mechanis...

Embodiment 2

[0145] like Figure 5 As shown, the same or corresponding components as those in the first embodiment are given the corresponding reference numerals as in the first embodiment. For the sake of brevity, only the points of difference from the first embodiment are described below. The difference between the second embodiment and the first embodiment is:

[0146] further, as Figure 5 As shown, the export component 43 includes:

[0147] A frame 431, the frame 431 is installed on the workbench 1 and used to support the output end of the discharge pipe 322;

[0148] A rotating member 432, the rotating member 432 is installed on the frame 431, which includes a support 4321, a rotating shaft c4322 rotatably arranged on the support 4321 and disposed along the width direction of the workbench 1, and The windmill blades 4323 fixedly arranged on the rotating shaft c4322; and

[0149] The transmission member 433 is used for driving the rotating member 432 to rotate towards the directio...

Embodiment 3

[0164] With reference to Embodiment 1 and Embodiment 2, as Figure 16 As shown, the preparation process of a strong reflective pavement marking paint of the present invention is described, including the following steps:

[0165] Step 1, particle grinding, first put the particles 10 into the storage bin 311 from the feeding port 312, start the motor 3131, and break up the particles 10 by the disintegrating rack 3133, and then grind and crush them under the action of the grinding rack 3134. After being crushed into small volumes, it will spiral upward under the action of the crushing rack 3134;

[0166] In step 2, the particles are discharged. The particles 10 after the swirl rise are output from the discharge port 314 into the discharge bin 321 under the action of the deflector 315. The tube 322 is ejected outward;

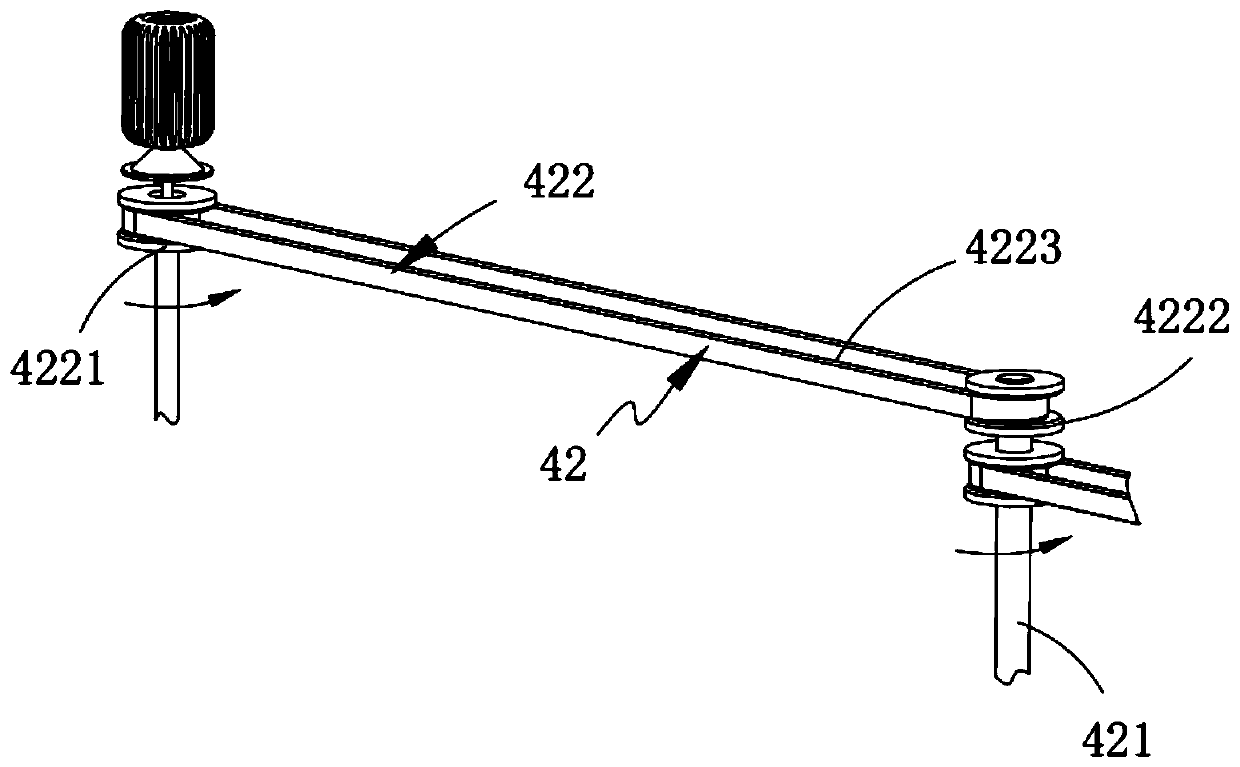

[0167] Step 3, the resin is discharged, synchronized with step 1, the first control member 422 rotates synchronously under the action of the motor 3131, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com