Spraying device for electric porcelain insulator production

A spraying device and insulator technology, applied in the direction of spraying device, etc., can solve problems such as gun needles are easy to adhere to paint dust, paint harmful smell, harm human body, etc., to achieve the effect of blocking pollution, preventing internal pollution, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

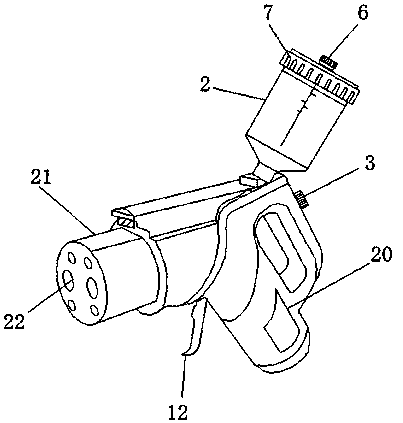

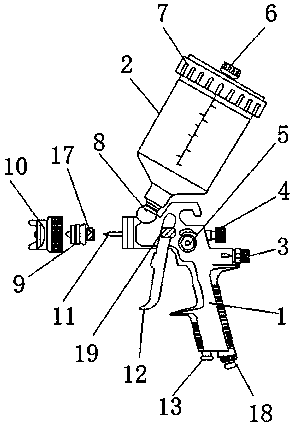

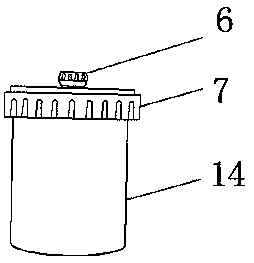

[0024] refer to Figure 1-4 , a spraying device for producing electric porcelain insulators, comprising an inner frame 1, a gun body 20, a gun head 21 and a discharge port 22, the inside of the gun body 20 is provided with an inner frame 1, and the outer end of the gun body 20 is fixed A gun head 21 is connected, the end of the gun head 21 is provided with a discharge port 22, the bottom side of the inner frame 1 is provided with an air interface 13, and the other side of the bottom of the inner frame 1 is provided with an air conditioning Knob 18, the front middle part of the inner frame 1 is provided with a spray width adjustment knob 5, one side of the spray width adjustment knob 5 is provided with a trigger 12, and the trigger 12 is provided with a needle baffle 19, the inner One end of the front of the frame 1 is provided with a paint flow adjustment knob 4, and a spraying air pressure adjustment knob 3 is arranged below the paint flow adjustment knob 4, and the other end...

Embodiment 2

[0026] refer to Figure 1-4 , a spraying device for producing electric porcelain insulators, comprising an inner frame 1, a gun body 20, a gun head 21 and a discharge port 22, the inside of the gun body 20 is provided with an inner frame 1, and the outer end of the gun body 20 is fixed A gun head 21 is connected, the end of the gun head 21 is provided with a discharge port 22, the bottom side of the inner frame 1 is provided with an air interface 13, and the other side of the bottom of the inner frame 1 is provided with an air conditioning Knob 18, the front middle part of the inner frame 1 is provided with a spray width adjustment knob 5, one side of the spray width adjustment knob 5 is provided with a trigger 12, and the trigger 12 is provided with a needle baffle 19, the inner One end of the front of the frame 1 is provided with a paint flow adjustment knob 4, and a spraying air pressure adjustment knob 3 is arranged below the paint flow adjustment knob 4, and the other end...

Embodiment 3

[0028] refer to Figure 1-4 , a spraying device for producing electric porcelain insulators, comprising an inner frame 1, a gun body 20, a gun head 21 and a discharge port 22, the inside of the gun body 20 is provided with an inner frame 1, and the outer end of the gun body 20 is fixed A gun head 21 is connected, the end of the gun head 21 is provided with a discharge port 22, the bottom side of the inner frame 1 is provided with an air interface 13, and the other side of the bottom of the inner frame 1 is provided with an air conditioning Knob 18, the front middle part of the inner frame 1 is provided with a spray width adjustment knob 5, one side of the spray width adjustment knob 5 is provided with a trigger 12, and the trigger 12 is provided with a needle baffle 19, the inner One end of the front of the frame 1 is provided with a paint flow adjustment knob 4, and a spraying air pressure adjustment knob 3 is arranged below the paint flow adjustment knob 4, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com