Laser cleaning system and method

A laser cleaning and laser technology, applied in the field of laser cleaning systems, can solve the problems of increasing equipment complexity, complex and cumbersome process, unfavorable promotion of laser cleaning industrialization, etc., and achieve the effect of online non-contact detection and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

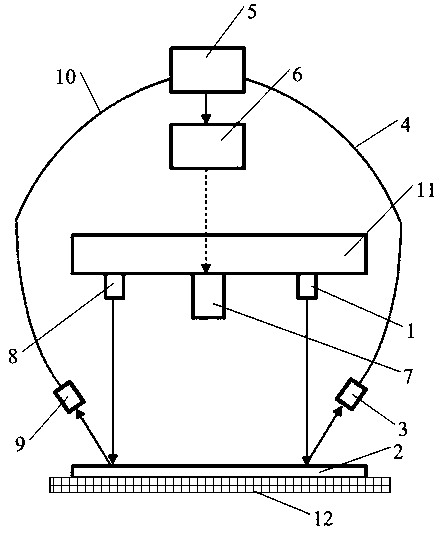

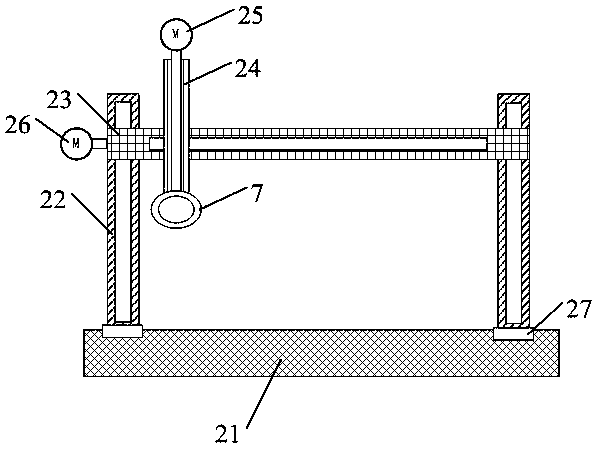

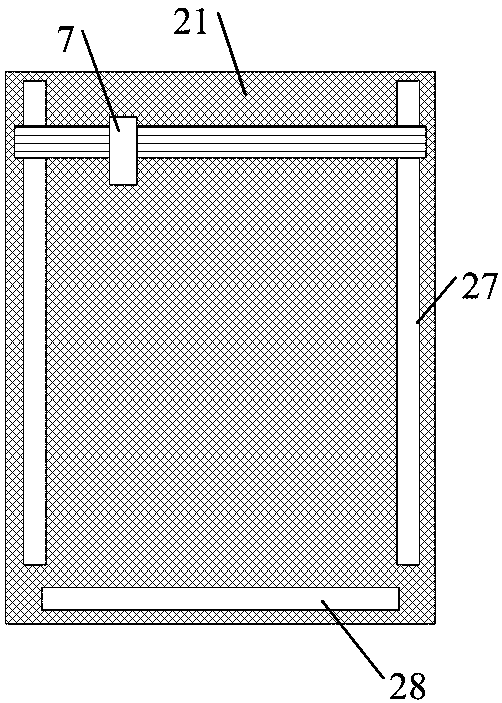

[0054] The invention provides a laser cleaning system, such as Figures 1 to 3 As shown, it includes: a connection mechanism 11, a control terminal 6, a spectrometer 5 and a first laser probe 3;

[0055] The connection mechanism 11 is provided with a first Q-switched laser 1 and a laser cleaning head 7; the spectrometer 5, the first Q-switched laser 1 and the laser cleaning head 7 are respectively connected to the control terminal 6; the spectrometer 5 is connected to the first laser probe 3 by communication The control terminal 6 controls the first Q-switched laser 1 to project the spectral value of the first preset threshold on the cleaning sample 12, and the spectrometer 5 collects the spectrum projected by the first Q-switched laser 1 on the cleaning sample 12 through the first laser probe 3 information, and transmit the spectral information to the control terminal 6; the control terminal analyzes the thickness of the coating on the sample to be cleaned and the ratio of va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com