Rotten wood compacted material based on high-frequency no-adhesive compacting technology and method

A high-frequency, dead wood technology, used in wood processing, wood processing equipment, wood processing details, etc., can solve the problems of the engraver's successful carving, high waste rate, and dead wood breakage, etc. The effect of improving the flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

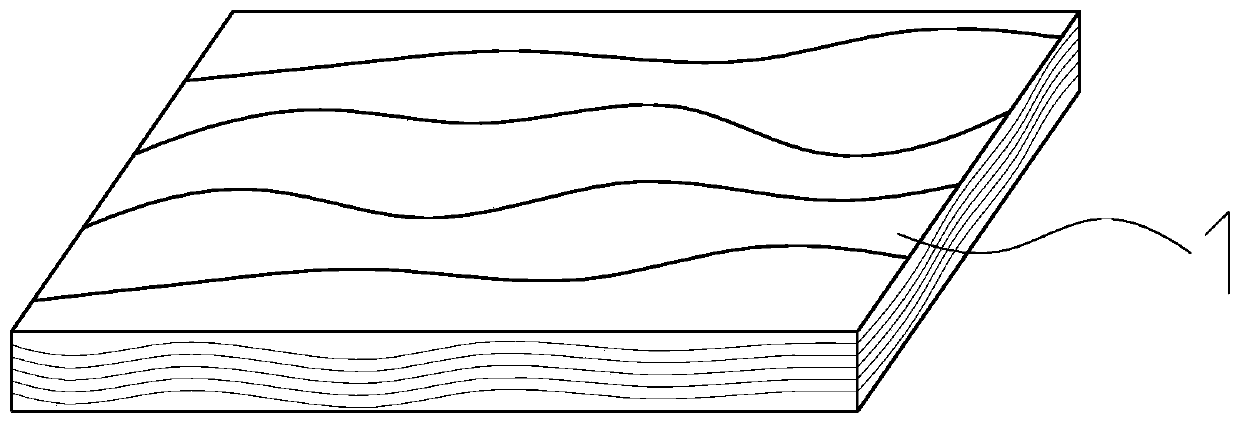

[0057] Embodiment 1 compacts the rotten plank separately

[0058] This embodiment provides a kind of dead wood compacted material, the preparation method of this dead wood compacted material comprises the following steps:

[0059] a. High-temperature and high-humidity treatment: place the rotten wood boards in the drying cellar for heating and humidification, adjust the relative humidity in the drying cellar to 50%, the temperature to 50°C, the heating and humidification time to 3 hours, and then adjust the relative humidity in the drying cellar to 80% , the temperature is 44°C, the heating and humidification time is 20 minutes, and the high-temperature and high-humidity treatment rotten wood board is obtained;

[0060] b. Drying treatment: reduce the rotten wood boards treated with high temperature and high humidity to room temperature, equilibrate at room temperature for 12, then place the dried rotten wood boards in a drying cellar, heat up to 120°C, and keep them warm for ...

Embodiment 2

[0078] This embodiment provides a kind of dead wood compacted material, the preparation method of this dead wood compacted material comprises the following steps:

[0079] a. High-temperature and high-humidity treatment: place the rotten wood boards in the drying cellar for heating and humidification, adjust the relative humidity in the drying cellar to 50%, the temperature to 50°C, the heating and humidification time to 3 hours, and then adjust the relative humidity in the drying cellar to 80% , the temperature is 44°C, the heating and humidification time is 20 minutes, and the high-temperature and high-humidity treatment rotten wood board is obtained;

[0080] b. Drying treatment: reduce the rotten wood boards treated with high temperature and high humidity to room temperature, equilibrate at room temperature for 12, then place the dried rotten wood boards in a drying cellar, heat up to 120°C, and keep them warm for 1 day to obtain dry rotten wood boards ;

[0081] c. Heati...

Embodiment 3

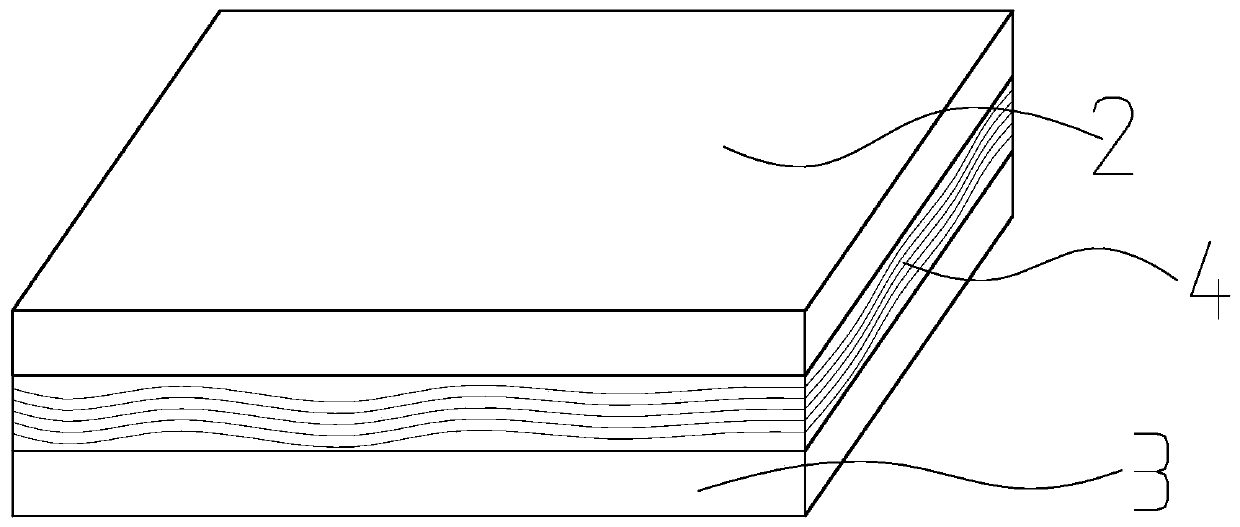

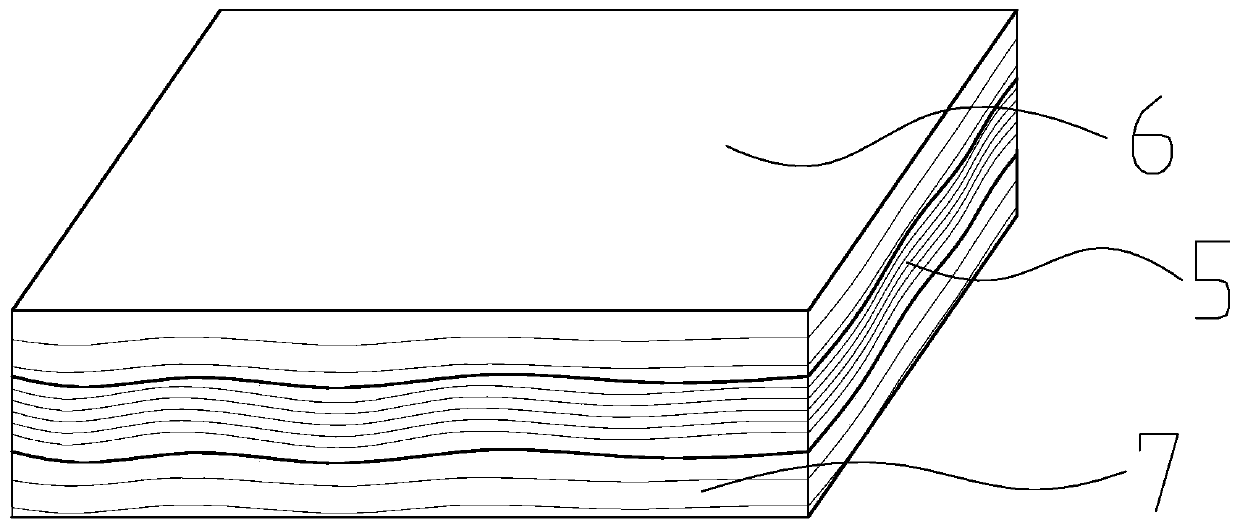

[0093] This embodiment provides a kind of rotten wood compacted material, the rotten wood compacted material is made by high frequency heat bonding of compacted wood and rotten wood board, the preparation method of the rotten wood compacted material comprises the following steps:

[0094] S1: Prepare pretreated decayed wood boards by the method of Example 1;

[0095] S2: lamination treatment: laminating the pretreated decayed wood board and the compacted wood at intervals, and placing a PVB intermediate film between the adjacent decayed wood boards and the compacted wood to obtain a laminated wood board;

[0096] S3: heat-sealing treatment: heat the laminated wood board after lamination treatment to 130° C. with a high frequency, compress the dry decayed wood board with a compression rate of 4%-6%, and keep the pressure for 3 minutes to obtain a heat-sealed wood board;

[0097] S4: cooling treatment: cooling the heat-bonded wood board to 70°C to obtain the rotten wood compacte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap