A kind of food industry wastewater treatment process

A technology of industrial wastewater and treatment process, which is applied in the fields of food industry wastewater treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems of incomplete removal of nitrogen elements, incomplete sewage treatment, and water quality. , to achieve the effect of improving the flocculation capacity and the removal rate of dissolved organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

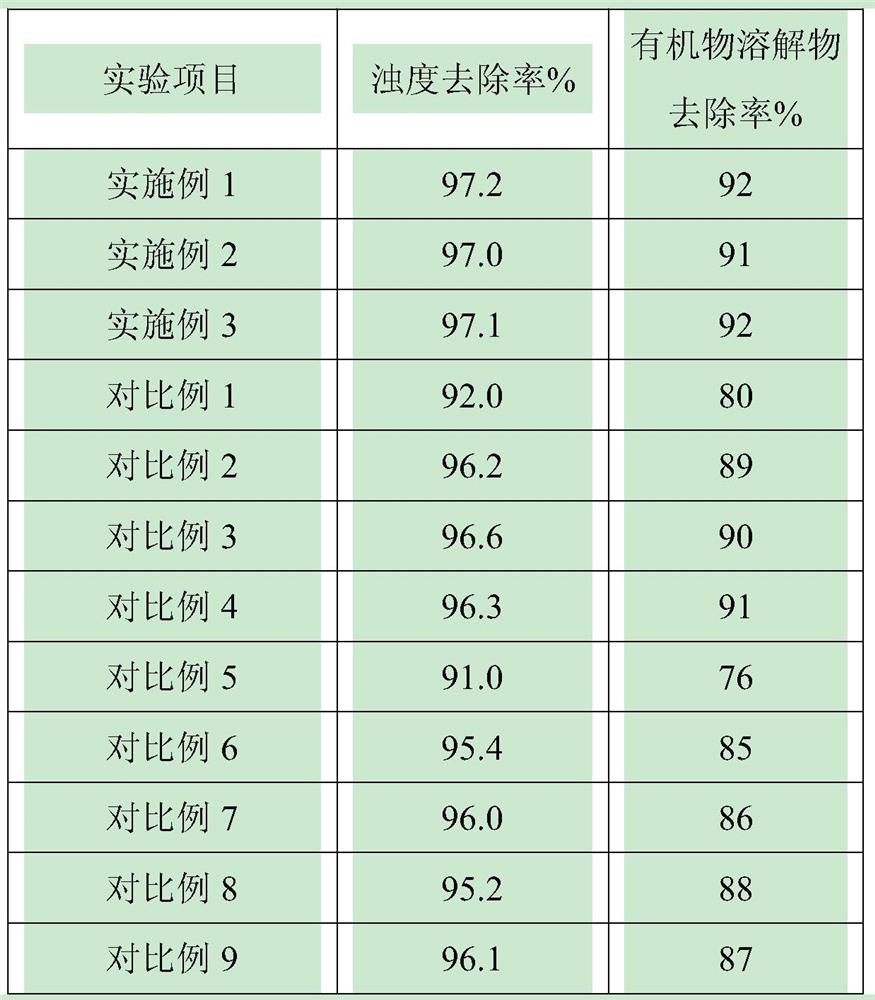

Examples

Embodiment 1

[0029] A food industry wastewater treatment process, specifically according to the following steps: A. Primary filtration and sedimentation: First, the food industry wastewater flows through multiple grids, and then is discharged into a sedimentation tank, and flocculants are added for flocculation, and air is blown in, and then Carry out sedimentation treatment, promptly obtain the supernatant of industrial waste water; B, ultraviolet ray sterilization and adjust pH value: the industrial waste water supernatant described in step A is discharged into the acid-base adjustment pond, carries out sterilization and disinfection with ultraviolet light earlier, removes peculiar smell, then adjust its pH to 6.5 to obtain the industrial waste water after adjusting the pH value; The air pool uses anaerobic bacteria to decompose the macromolecular carbon source and macromolecular nitrogen source, and then passes it into the aerobic pool to use aerobic bacteria to decompose the small molec...

Embodiment 2

[0033] A food industry wastewater treatment process, specifically according to the following steps: A. Primary filtration and sedimentation: First, the food industry wastewater flows through multiple grids, and then is discharged into a sedimentation tank, and flocculants are added for flocculation, and air is blown in, and then Carry out sedimentation treatment, promptly obtain the supernatant of industrial waste water; B, ultraviolet ray sterilization and adjust pH value: the industrial waste water supernatant described in step A is discharged into the acid-base adjustment pond, carries out sterilization and disinfection with ultraviolet light earlier, removes peculiar smell, then adjust its pH to 5.5 to obtain the industrial waste water after adjusting the pH value; The air pool uses anaerobic bacteria to decompose the macromolecular carbon source and macromolecular nitrogen source, and then passes it into the aerobic pool to use aerobic bacteria to decompose the small molec...

Embodiment 3

[0037] A food industry wastewater treatment process, specifically according to the following steps: A. Primary filtration and sedimentation: First, the food industry wastewater flows through multiple grids, and then is discharged into a sedimentation tank, and flocculants are added for flocculation, and air is blown in, and then Carry out sedimentation treatment, promptly obtain the supernatant of industrial waste water; B, ultraviolet ray sterilization and adjust pH value: the industrial waste water supernatant described in step A is discharged into the acid-base adjustment pond, carries out sterilization and disinfection with ultraviolet light earlier, removes peculiar smell, then adjust its pH to 7.5 to obtain the industrial waste water after adjusting the pH value; The air pool uses anaerobic bacteria to decompose the macromolecular carbon source and macromolecular nitrogen source, and then passes it into the aerobic pool to use aerobic bacteria to decompose the small molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com