Preparation method for phosphate ester

A phosphate ester and phosphorylation technology, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as deepening chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

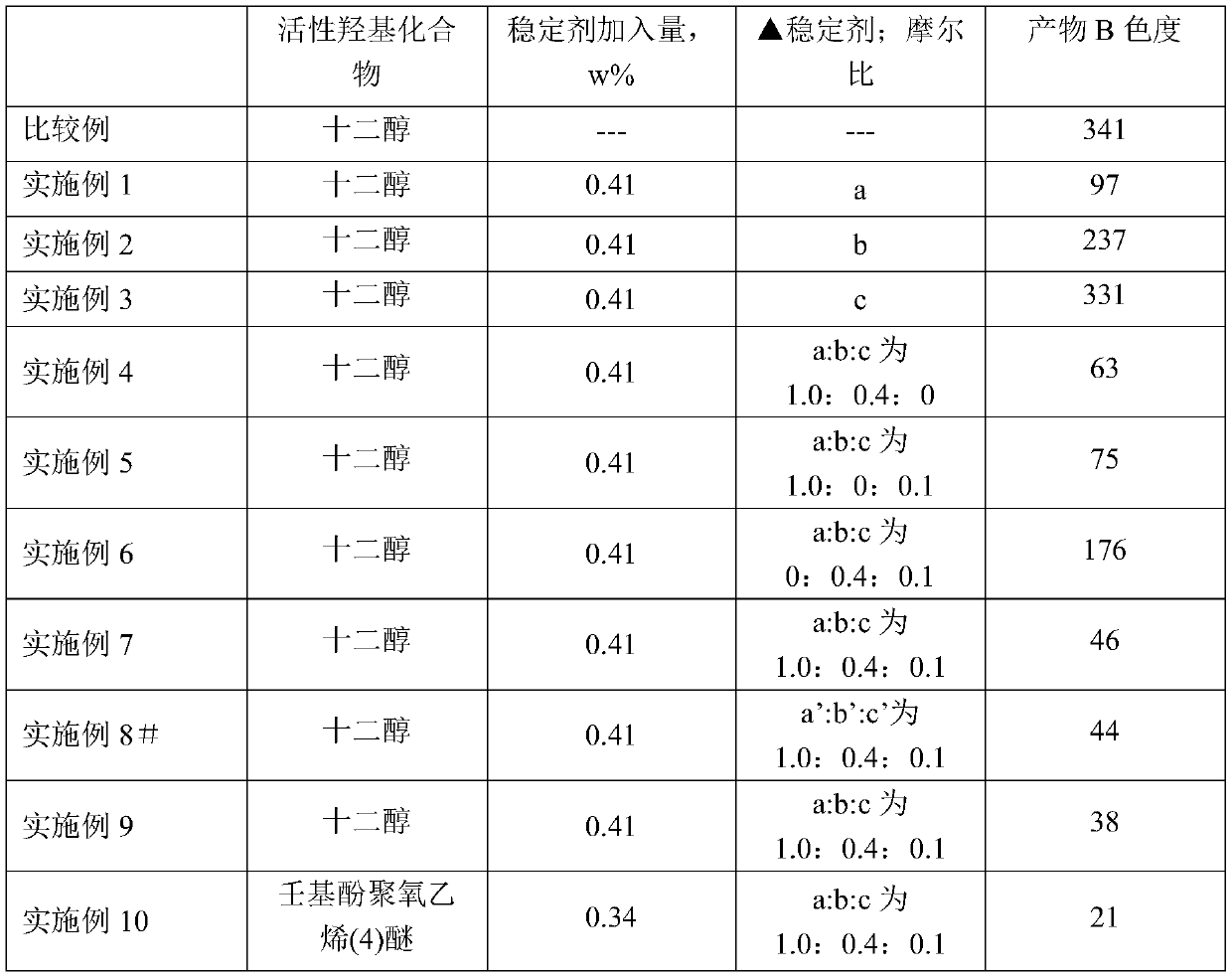

Examples

Embodiment 1

[0044] 1. Phosphate ester preparation

[0045] The difference with the comparative example is that step (2) adds a stabilizer, and the stabilizer is sodium phosphite.

[0046] Add 200.00g (1.08mol) of n-dodecyl alcohol into a 500ml three-neck flask, raise the temperature and turn on the stirring switch; control the temperature at 52±2°C, and add 68.16g of phosphorus pentoxide (0.96mol in terms of phosphoric acid) within half an hour; Nitrogen was filled, and the temperature was kept at 70°C for 2 hours, then 2.68g of pure water and 1.10g of sodium phosphite were added, the temperature was controlled at 70°C, and the temperature was kept at this temperature for 4 hours to obtain the phosphate ester product A. The chromaticity obtained by analyzing the method described in "GB3143-82 Liquid Chemical Product Color Determination Method (Hazen Unit—Platinum-Cobalt Color)" is 38.

[0047] 2. Evaluation of color stability at high temperature

[0048] Add 100 grams of the above-menti...

Embodiment 2

[0050] 1. Phosphate ester preparation

[0051] The difference with the comparative example is that step (2) adds a stabilizer, and the stabilizer is sodium stearate.

[0052] Add 200.00g (1.08mol) of n-dodecyl alcohol into a 500ml three-neck flask, raise the temperature and turn on the stirring switch; control the temperature at 52±2°C, and add 68.16g of phosphorus pentoxide (0.96mol in terms of phosphoric acid) within half an hour; Nitrogen was filled, and the temperature was kept at 70°C for 2 hours, then 2.68g of pure water and 1.10g of sodium stearate were added, the temperature was controlled at 70°C, and the temperature was kept at this temperature for 4 hours to obtain the phosphate ester product A. The chromaticity obtained by analyzing the method described in "GB3143-82 Liquid Chemical Product Color Determination Method (Hazen Unit—Platinum-Cobalt Color)" is 41.

[0053] 2. Evaluation of color stability at high temperature

[0054] Add 100 grams of the above-mention...

Embodiment 3

[0056] 1. Phosphate ester preparation

[0057] The difference with the comparative example is that step (2) adds a stabilizer, and the stabilizer is sodium borate.

[0058] Add 200.00g (1.08mol) of n-dodecyl alcohol into a 500ml three-neck flask, raise the temperature and turn on the stirring switch; control the temperature at 52±2°C, and add 68.16g of phosphorus pentoxide (0.96mol in terms of phosphoric acid) within half an hour; Nitrogen was filled, and the temperature was kept at 70°C for 2 hours, then 2.68g of pure water and 1.10g of sodium borate were added, the temperature was controlled at 70°C, and the temperature was kept at this temperature for 4 hours to obtain the phosphate ester product A. The chromaticity obtained by analyzing the method described in "GB3143-82 Liquid Chemical Product Color Determination Method (Hazen Unit—Platinum-Cobalt Color)" is 41.

[0059] 2. Evaluation of color stability at high temperature

[0060] Add 100 grams of the above-mentioned p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com