Closed storage tank cathode protection potential monitoring device

A technology of potential monitoring and cathodic protection, which is applied in the field of safety monitoring and corrosion protection, can solve the problems of a single monitoring device and the inability to monitor and evaluate the cathodic protection effect of storage tanks, and achieve the effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

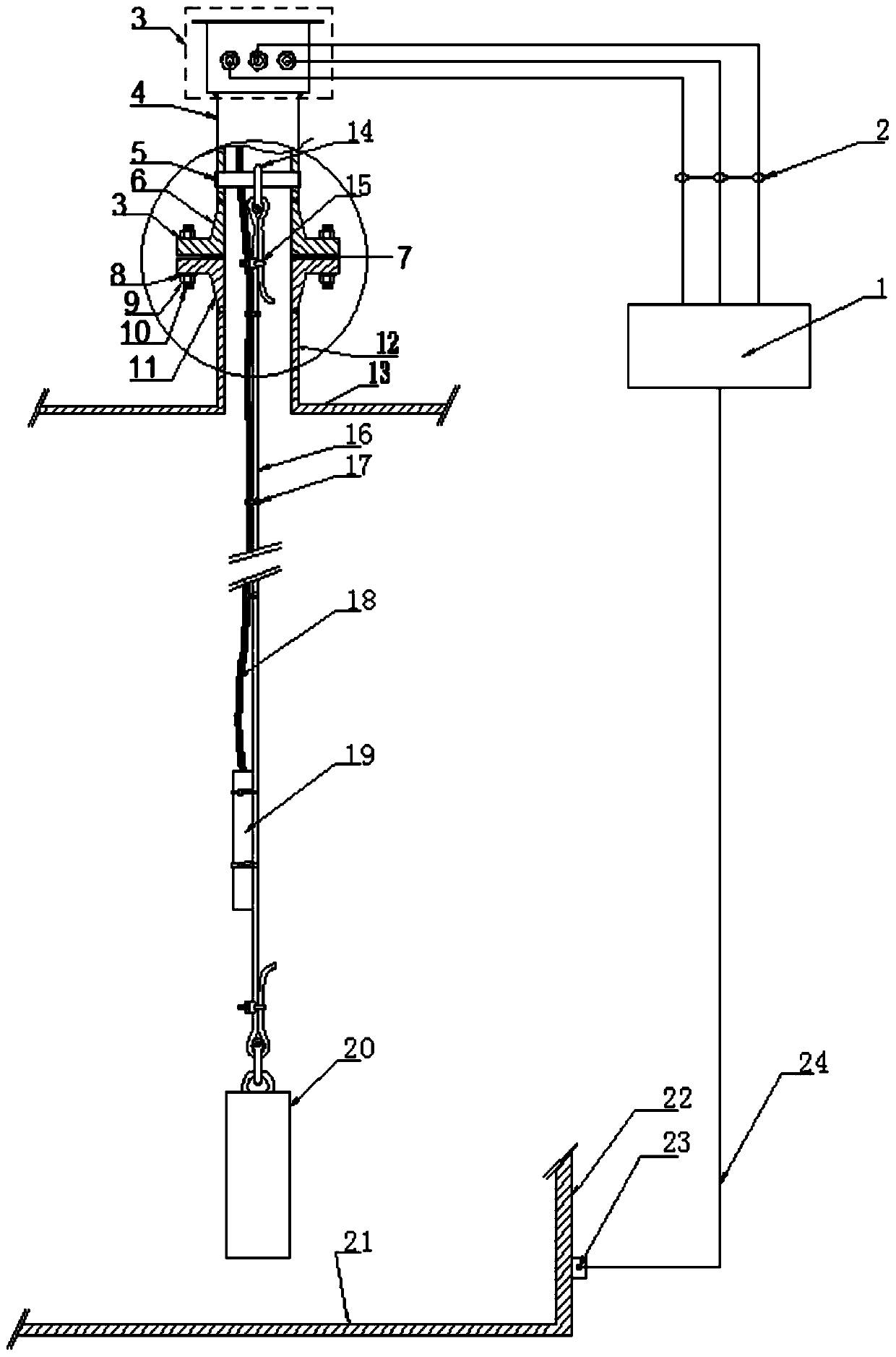

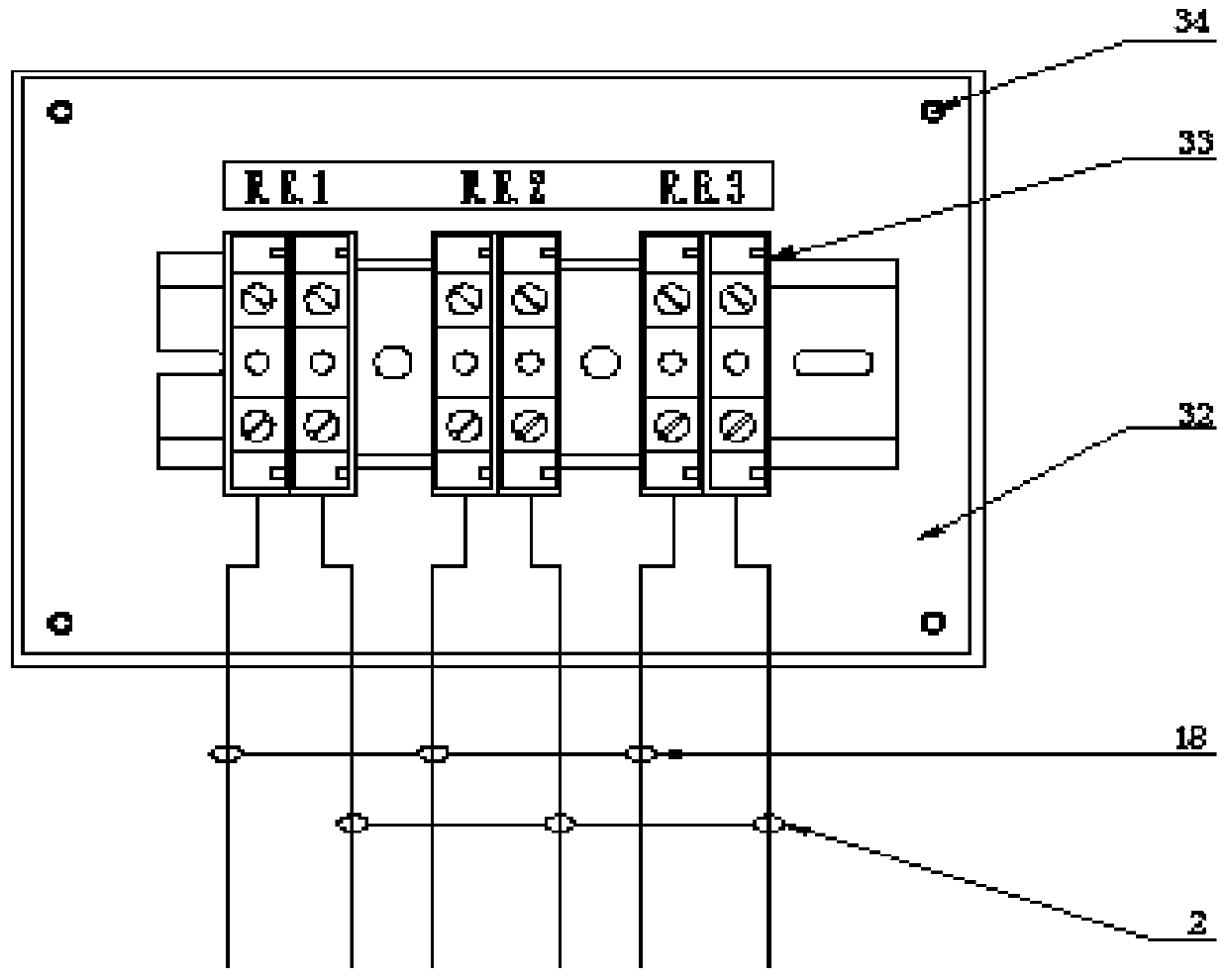

[0033] A closed storage tank cathodic protection potential monitoring device, comprising a monitor 1 and a reference electrode 19, the monitor 1 and the reference electrode 19 are connected by a cable, and the monitor 1 and the closed storage tank are connected by a cable connected, the reference electrode 19 is located inside the closed storage tank, and the monitor 1 is located outside the closed storage tank.

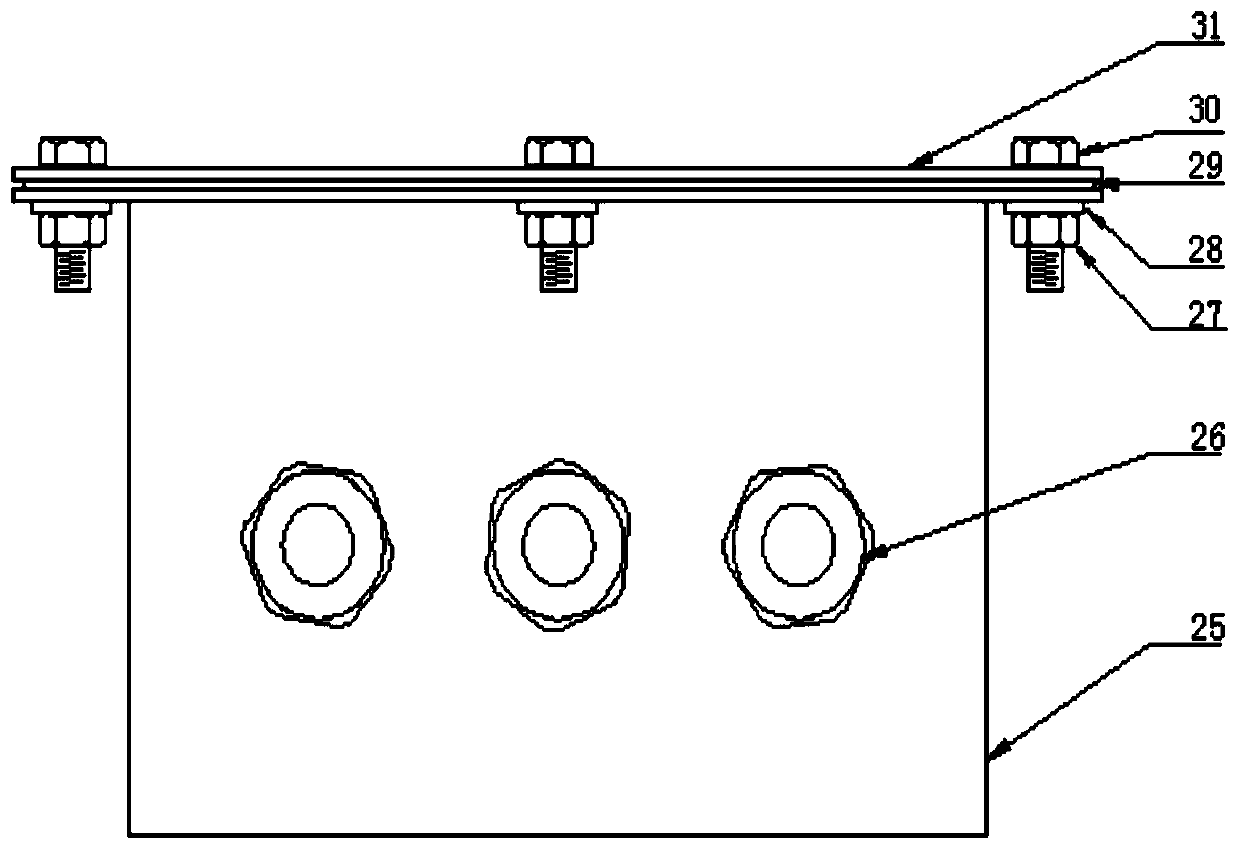

[0034] Specifically, the monitor and the reference electrode are connected through the connecting cable 2, and the roof 13 of the closed storage tank has an opening to match the cable to ensure the airtightness of the storage tank. A sealing ring can also be set at the opening of the closed storage tank, and the cable Through the sealing ring, the sealed connection between the reference electrode and the monitor is realized.

[0035] The monitor and the tank are connected by a monitoring cable 24, and a monitoring cable connector 23 is arranged at a position to be me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com