Textile technology for textile production

A process and sliver technology, which is applied in the textile process for textile production and the application field of textile process, can solve the problems of inconvenient processing of burrs on the surface of spun yarn, can not meet the needs of workers, affect the quality of textile production, etc., so as to improve textile efficiency. , to meet the needs of use, reduce the effect of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

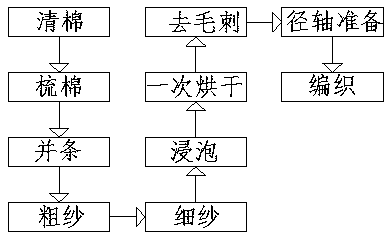

[0029] A textile process for textile production, the textile process for textile production comprises the steps of:

[0030] (1) Cotton cleaning, the raw cotton is opened, and the raw cotton after cleaning is made into a lap with uniform thickness and good shape;

[0031] (2) Carding, separating the cotton rolls in step (1) into fibers, removing small impurities in the cotton rolls, and making slivers that meet the requirements;

[0032] (3) Draw the sliver, place the sliver made in step (2) in an orderly manner, and set aside;

[0033] (4) roving, pulling and twisting the sliver in step (3) to make roving;

[0034] (5) Spun yarn, stretching the roving in step (4) to the required thickness according to the needs of spinning;

[0035] (6) soaking, place the spun yarn made in step (5) under the condition of water temperature of 90°C, add water to soak;

[0036] (7) Once drying, the spun yarn soaked in step (6) is dried by a dryer;

[0037] (8) Deburring, deburring the spun y...

Embodiment 2

[0051] A textile process for textile production, the textile process for textile production is as follows:

[0052] (1) Cotton cleaning, the raw cotton is opened, and the raw cotton after cleaning is made into a lap with uniform thickness and good shape;

[0053] (2) Carding, separating the cotton rolls in step (1) into fibers, removing small impurities in the cotton rolls, and making slivers that meet the requirements;

[0054] (3) Draw the sliver, place the sliver made in step (2) in an orderly manner, and set aside;

[0055] (4) roving, pulling and twisting the sliver in step (3) to make roving;

[0056] (5) Spun yarn, stretching the roving in step (4) to the required thickness according to the needs of spinning;

[0057] (6) soaking, place the spun yarn made in step (5) under the condition of water temperature of 90°C, add water to soak;

[0058] (7) Once drying, the spun yarn soaked in step (6) is dried by a dryer;

[0059] (8) Deburring, deburring the spun yarn after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com