Spontaneous heating type floor for exercise room and pavement method of spontaneous heating type floor

A laying method and self-heating technology, applied in the field of flooring, can solve the problems of increased manufacturing costs, difficult production and processing, and low heating efficiency of heating wires, so as to reduce the incidence of conductive leakage, reduce leakage safety hazards, and improve experience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

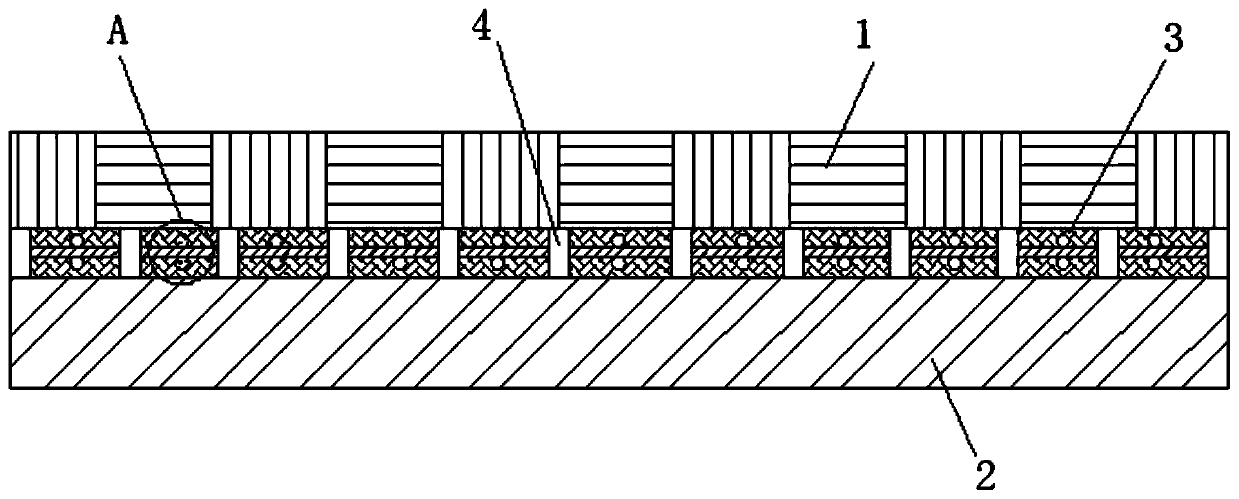

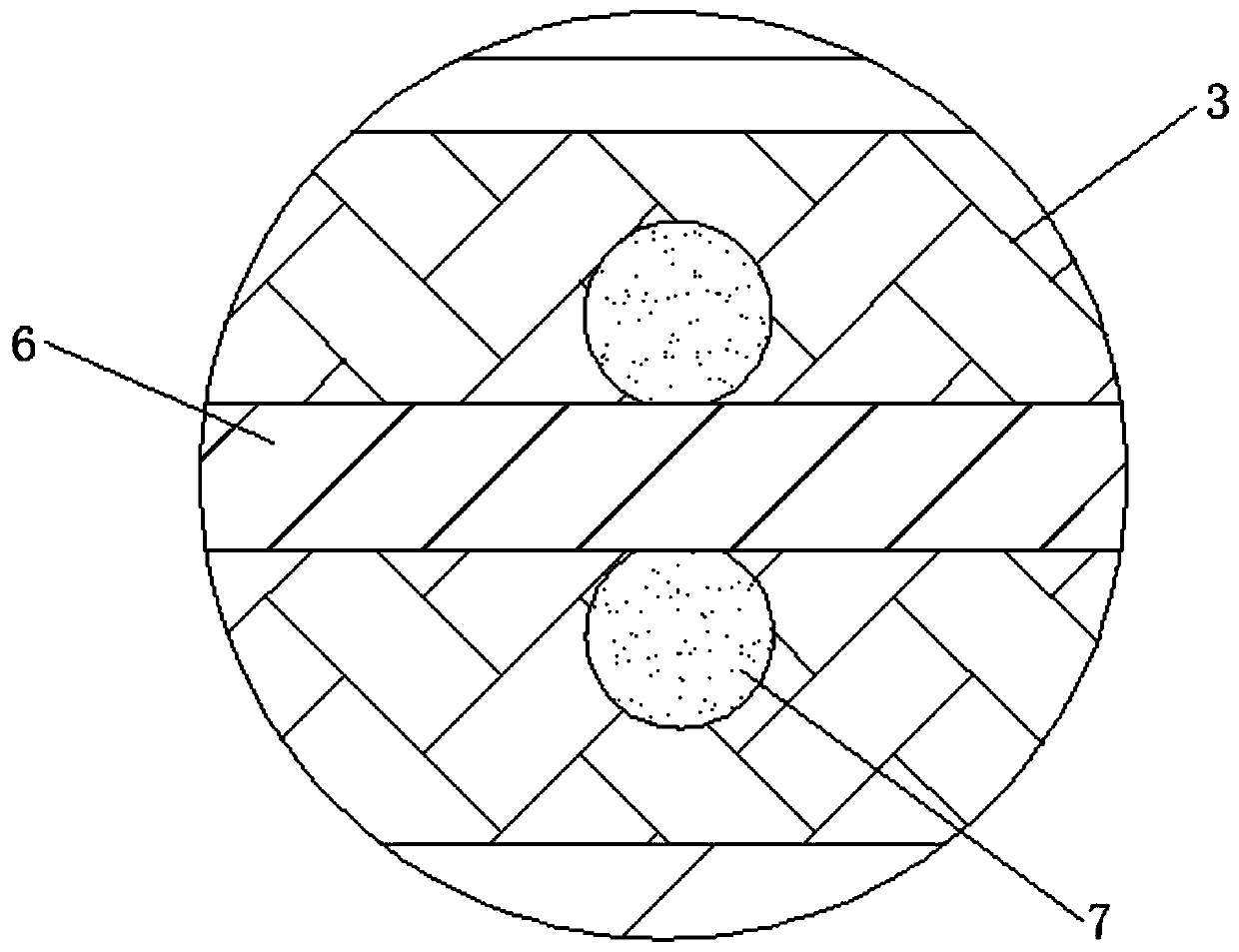

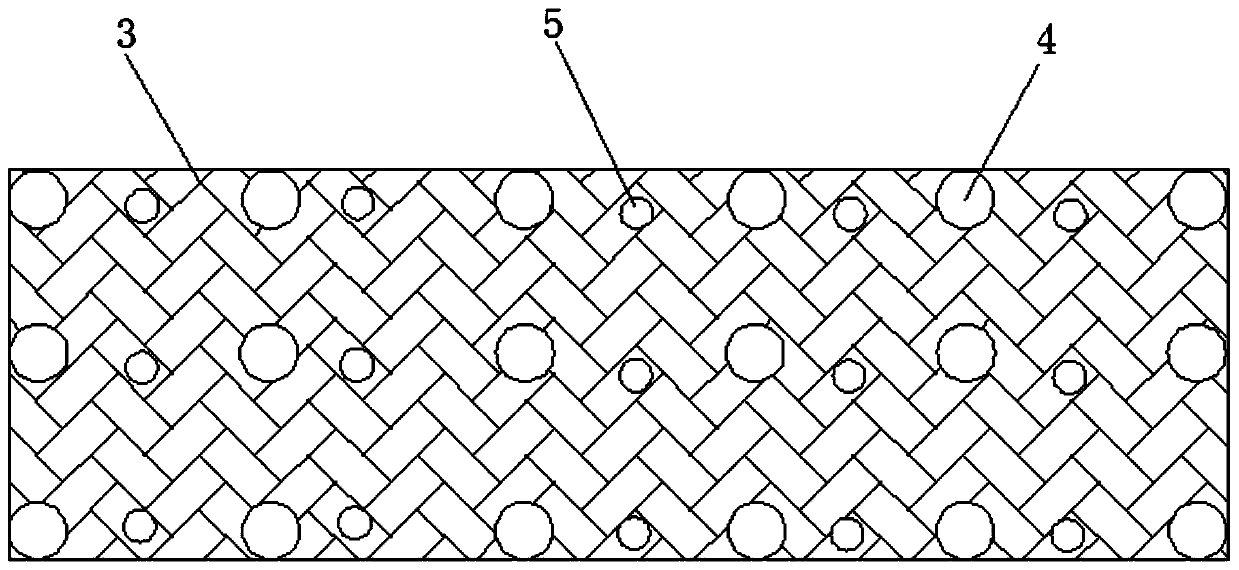

[0041] see figure 1 and image 3 , a self-heating floor for a work room, including a self-heating floor body, the self-heating floor body includes a self-heating board body 2, a heat-conducting decorative panel 1 is provided on the upper side of the self-heating board body 2, and a heat-conducting decorative panel 1 Between the self-heating plate body 2, there is a fast-heating heat-conducting interlayer 3, and there are criss-crossing through holes in the fast-heating heat-conducting interlayer 3, and the criss-crossing through holes include horizontal through holes and The hole communicates with the longitudinal through hole 5, and both the transverse through hole and the longitudinal through hole 5 are filled with moisture-discharging filling ropes 6. The rapid heat type heat conduction interlayer 3 is dug with a plurality of round through holes from top to bottom. The circular through-holes are distributed in a staggered manner, and the fast-heating and heat-conducting su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com