Clamping claw type water supply device and construction method thereof

A water feeder and claw-type technology, applied in the claw-type water feeder and its construction field, can solve the problems of low drilling efficiency, low loading and unloading efficiency, etc., and achieve the effects of improving drilling efficiency, reducing labor intensity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

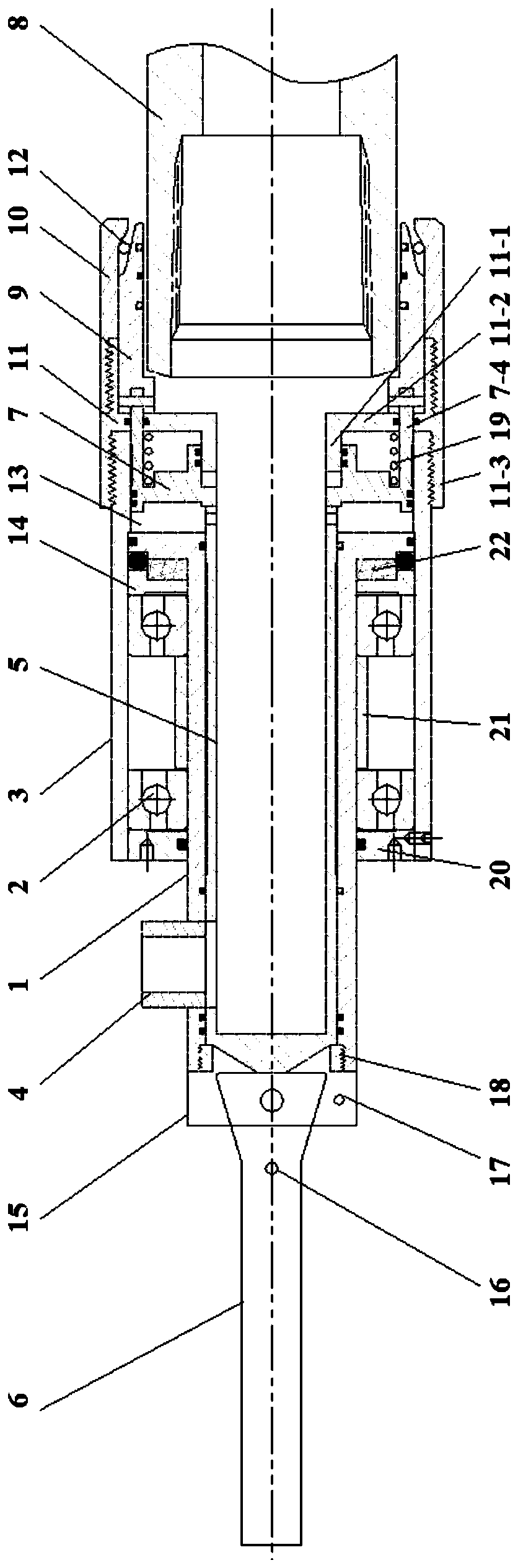

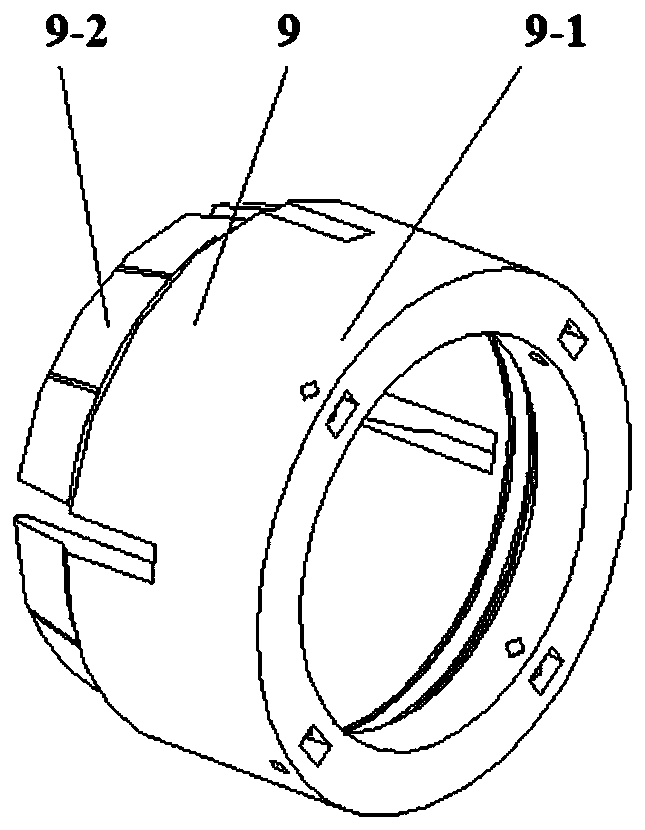

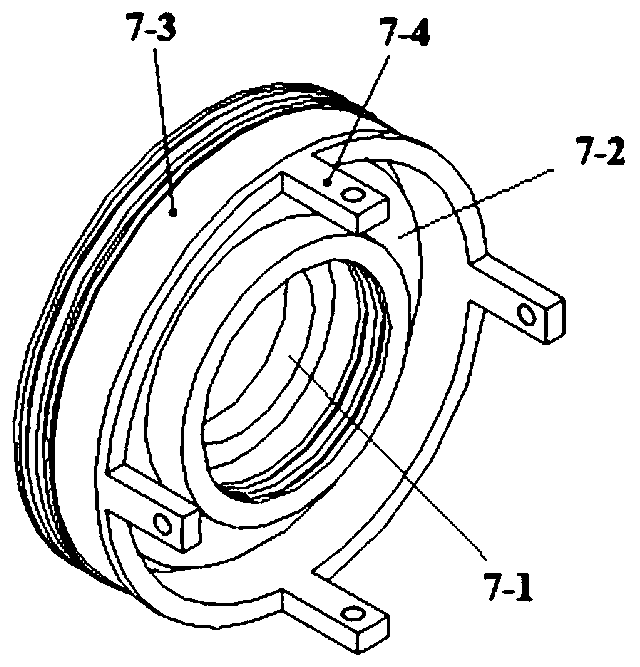

[0045] Such as Figures 1 to 3As shown, this embodiment provides a claw-type water feeder, which includes a mandrel 1, a bearing 2 and a bearing sleeve 3 arranged coaxially from the inside to the outside in sequence, and a high-pressure water interface is installed on the side wall of the mandrel 1 4; It also includes a force transmission hollow shaft 5 coaxially tightly fitted in the mandrel 1 and capable of moving axially, with one end closed and the other end open; the high-pressure water interface 4 is sealed and connected to the force transmission hollow shaft 5, which is used for the force transmission hollow shaft 5. The shaft 5 is connected with high-pressure water; the closed end of the power transmission hollow shaft 5 is provided with a rotating handle 6 that can push the power transmission hollow shaft 5 through rotation, and the open end of the power transmission hollow shaft 5 is provided with transmission shafts in sequence along the axial direction. The force h...

Embodiment 2

[0054] This embodiment also provides a construction method of a claw-type water feeder, comprising the following steps:

[0055] Step 1: Install and turn the rotary handle so that the positioning balls snap into the ball grooves, and the rotary handle is perpendicular to the force transmission hollow shaft;

[0056] Step 2: The trapezoidal end of the rotating handle pushes the force-transmitting hollow to move axially, and the force-transmitting hollow shaft pushes the annular piston to move axially, and shrinks the spring located between the annular piston and the piston cylinder, and the annular piston pushes the jaws to move axially. Move, the ball located between the wedge-shaped surface of the claw and the wedge-shaped inner wall presses the elastic claw tightly so that the elastic claw fastens the drill pipe coaxially sleeved in the claw;

[0057] Step 3: Introduce high-pressure water into the high-pressure water interface, and the high-pressure water enters the annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com