Waste disposal device with functions of energy saving and emission reduction

A waste treatment device, energy saving and emission reduction technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of increasing incineration time, inapplicability, energy consumption, etc., achieve high efficiency of waste incineration, reduce slag discharge, The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

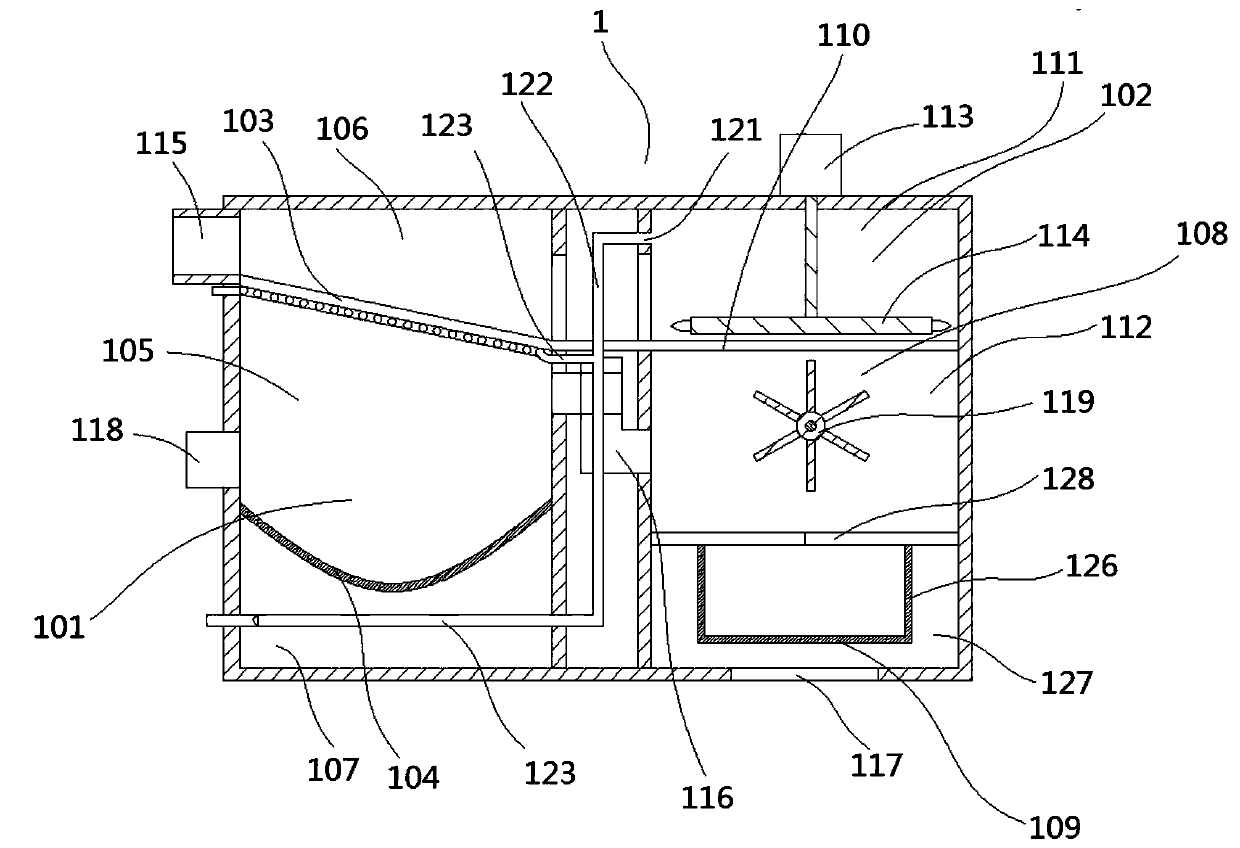

[0031] A garbage treatment device with energy-saving and emission-reduction functions, comprising an incinerator 1, and also includes a rubbish crushing and grinding device, the garbage crushing and grinding device is a garbage crushing device on the existing market, which is arranged before the incinerator 1, so that the garbage enters Before the incinerator 1, crushing and grinding treatment are carried out to ensure the adequacy of incineration in the subsequent incinerator 1.

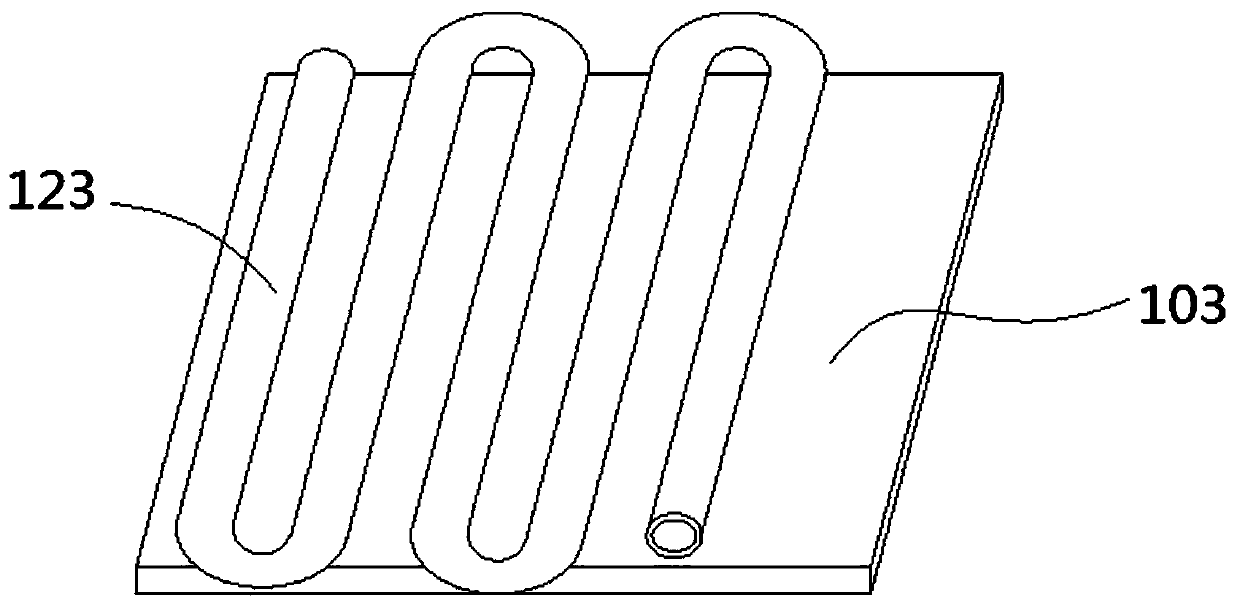

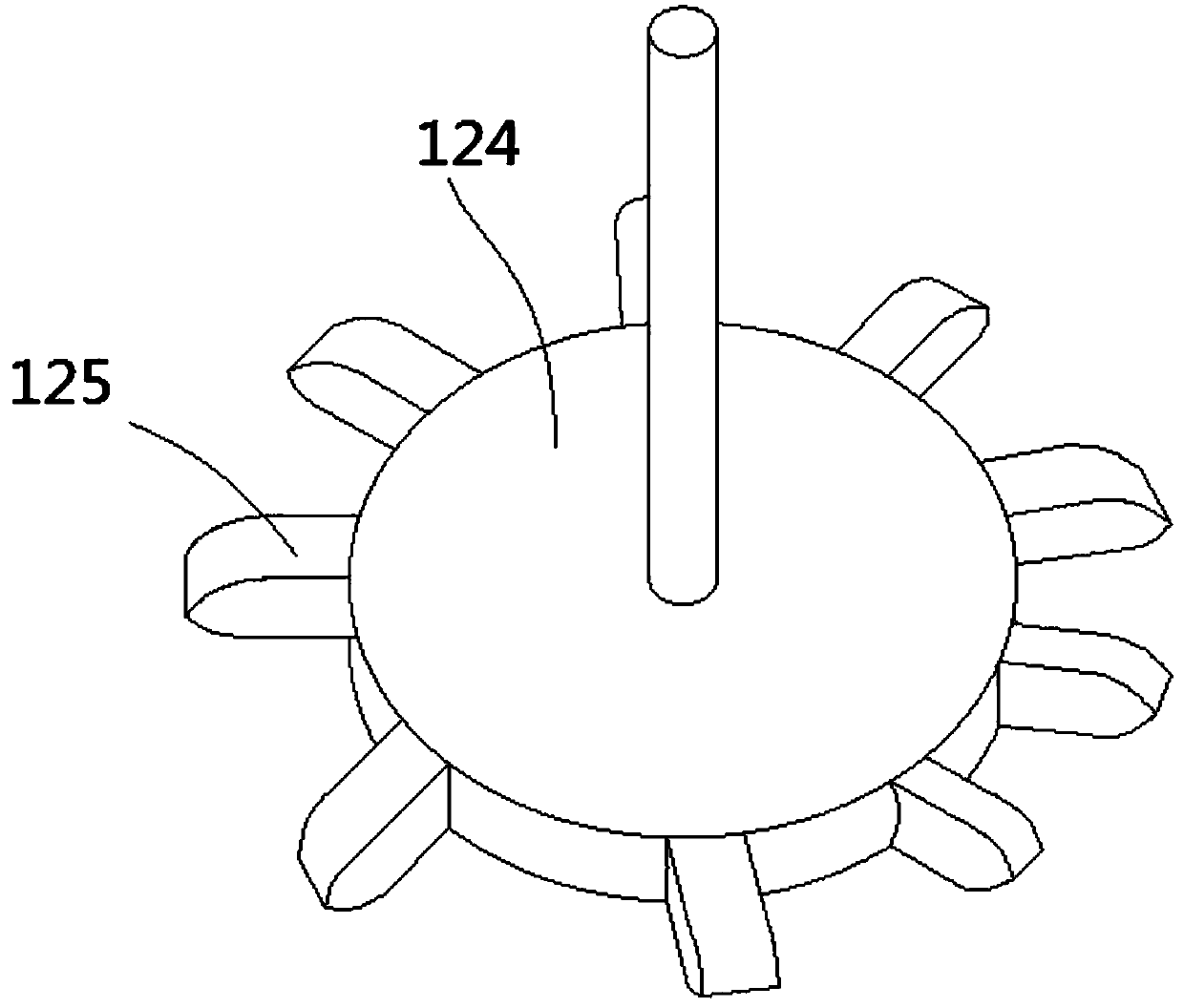

[0032] Such as figure 1 As shown, the incinerator 1 in the system has a special structural design, which includes a pretreatment chamber 101 and an incineration chamber 102. The first filter plate 103 and The downwardly recessed curved aluminum plate 104, the first filter plate 103 and the curved aluminum plate 104 separate the pretreatment chamber 101 from top to bottom into a large particle garbage room 105, a dust garbage room 106 and a water storage room 107. The incineration room 102 includes ...

Embodiment 2

[0040] In the present embodiment, the garbage disposal device includes a garbage crushing device 2, such as Figure 7 , Figure 8 As shown, the garbage shredding device 2 includes a shredding housing 201, and the inside of the shredding housing 201 forms a shredding chamber 221 with a square cross section.

[0041] In the crushing housing 201, that is, in the crushing chamber 221, there are longitudinally arranged rollers 204 and crushing bodies 205 distributed on the left and right sides of the rollers 204, the rollers 204 keep rotating under the action of the motor, and the crushing bodies 205 include Do horizontal rectilinear reciprocating motion and the transverse section is arc-shaped arc plate 206, the length direction of arc plate 206 is longitudinally arranged and the open end of arc plate 206 faces roller 204, and the inner wall of arc plate 206 is fixed with roller 204 The outer wall cooperates with the crushing block 207 for rubbish crushing, and the roller 204 and...

Embodiment 3

[0052] With embodiment 1 and embodiment 2, the garbage disposal device in the present embodiment promptly comprises the incinerator 1 in embodiment 1, by comprising the rubbish crushing device 2 in embodiment 2, and the rubbish crushing device 2 is replaced in embodiment 1 Common rubbish crushing and grinding device on the mentioned existing market.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com