Measuring scale for quickly and precisely measuring high-speed rail overhead lines

A technology of precise measurement and measuring ruler, which is applied in the direction of measuring device, mechanical measuring device, mechanical gap measurement, etc., can solve the problems of large size, inaccurate position of locator, and positioning failure, etc., to achieve fast and efficient measurement adjustment and improve accuracy The effect of sex and speed, convenient production workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

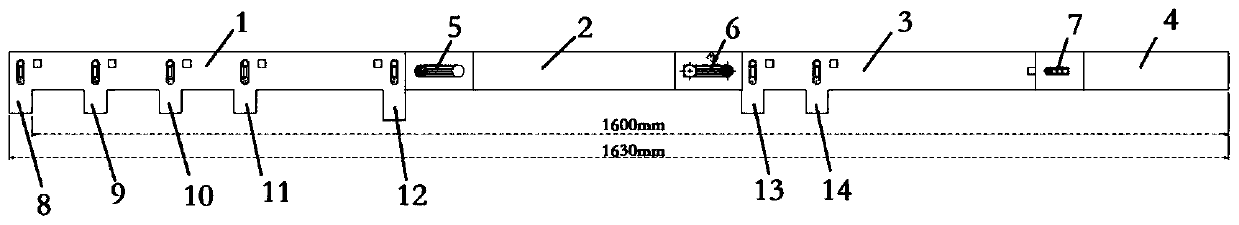

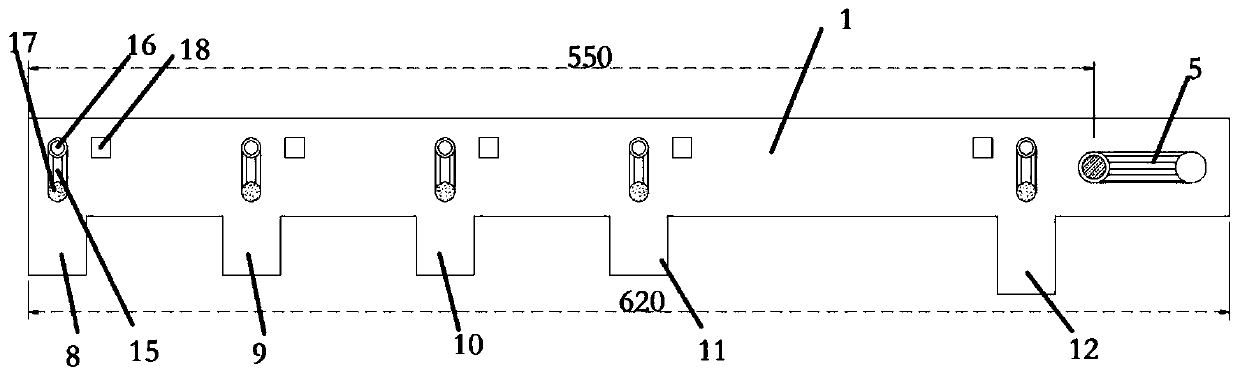

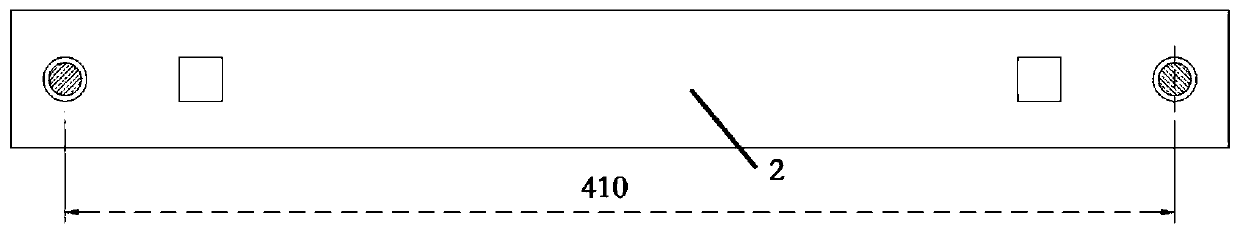

[0044] see Figure 1 to Figure 14 , the present embodiment provides a measuring ruler based on rapid and accurate measurement of high-speed rail catenary.

[0045] In this embodiment, the measuring ruler includes a ruler body, and the ruler body is a foldable rigid ruler structure, and the ruler body is successively composed of measuring ruler segment one at the end portion, measuring ruler segment two 2, and measuring ruler segment three 3 and the measuring ruler segment four 4 at the end and tail, the measuring ruler segment one 1 and the measuring ruler segment two 2 are foldable and connected by the rotating bayonet one 5, the measuring ruler segment two 2 and the measuring ruler segment three 3 Foldable connection is realized by rotating bayonet 2 6, measuring ruler segment 3 and measuring ruler segment 4 4 are foldably connected by rotating bayonet 3 7, and then become a four-section foldable whole, measuring ruler segment 1 1 1. Measuring ruler subsection two 2, measur...

Embodiment 2

[0053] Use measuring ruler in embodiment 1 to install and measure high-speed rail catenary arm arm, wherein: flat arm arm insulator end is 100mm apart from sleeve pipe single ear, and flat arm arm end excess length is 200mm (bearing cable seat is apart from flat arm arm end head 200mm), and the distance between the catenary cable seat and the double sleeve connector is 300mm. Such as Figure 15 As shown, the specific measurement steps are as follows:

[0054] S1. Hold the front of the measuring ruler, unfold the fixed block 1 8 and the fixed block 2 9, the distance between them is 100mm, and fix the single ear of the sleeve;

[0055] S2. Unfold the fixed block 4 11 and the fixed block 5 12. Since the fixed block 5 12 is 10mm longer than the other fixed blocks, the fixed block 5 12 just touches the end of the flat wrist arm. At this time, the fixed block 1 8 is It is the position of the double sleeve connector, and the fixed block four 11 is the position of the bearing cable ...

Embodiment 3

[0057] Use the measuring ruler in embodiment 1 to measure the installation of the inclined arm of the high-speed rail catenary. The standard structure height of the catenary arm of the high-speed rail is 1600mm. The requirement is that the height of the installation structure of the wrist arm (the distance between the bearing cable and the contact line) is 1600mm, the distance between the bearing cable and the centerline of the positioning tube is 1200mm, and the distance between the centerline of the positioning tube and the positioner is 400mm. The catenary cables and contact wires must be in the same vertical plane after installation, see the attached Figure 16 .

[0058] The specific measurement steps of this embodiment are as follows:

[0059] S1. Expand measuring ruler segment 1, measuring ruler segment 2, measuring ruler segment 3 3, measuring ruler segment 4 4 fold on measuring ruler segment 3, and the total length of measuring ruler is 1437mm at this time;

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com