Method and system for testing comprehensive performance of gas heating water heater

A comprehensive performance testing, gas heating technology, applied in the testing of machine/structural components, measuring devices, instruments, etc., can solve the problems of long query time, difficult test data query, etc., to achieve easy query, shorten query time, and reasonable evaluation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

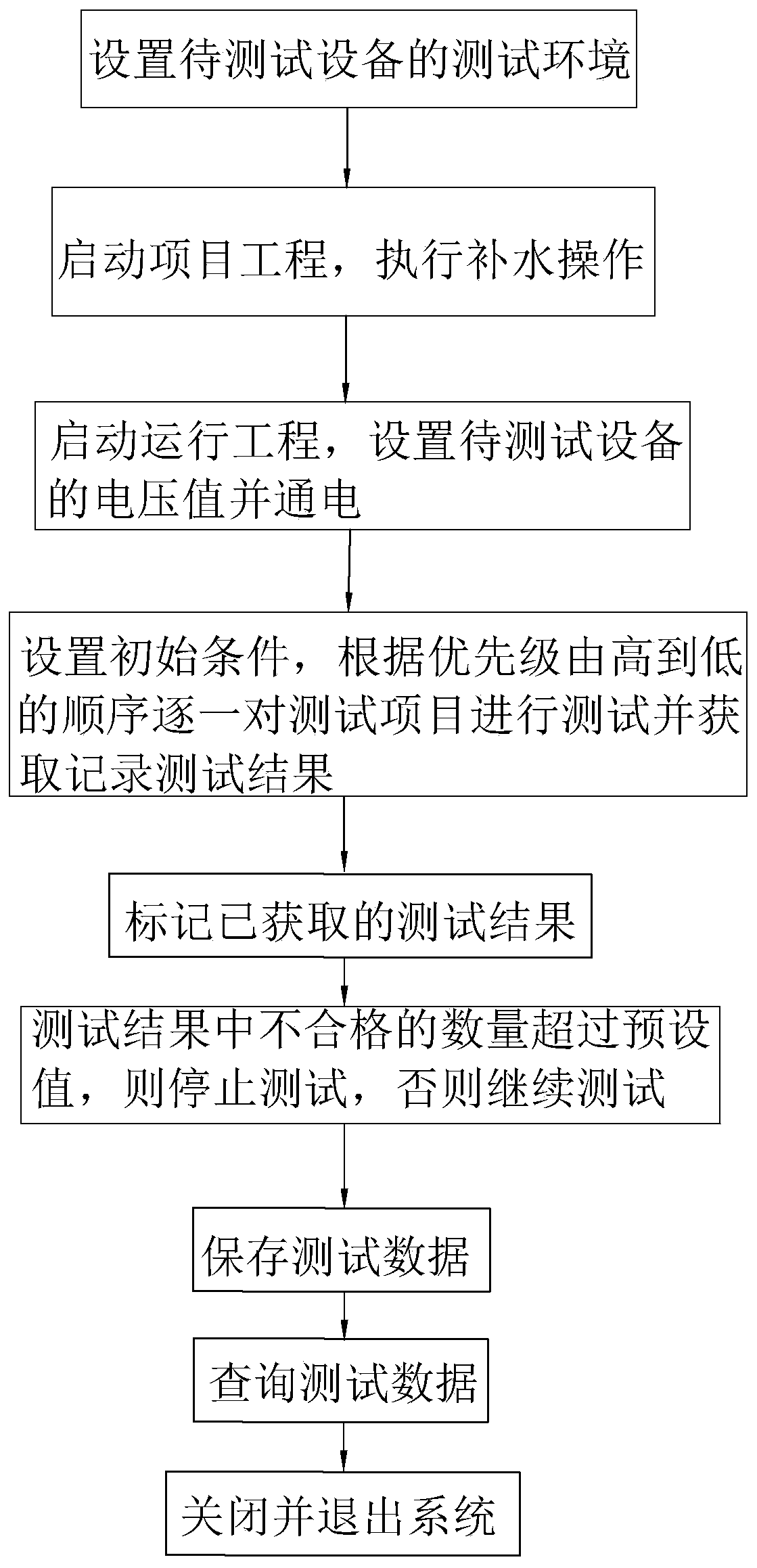

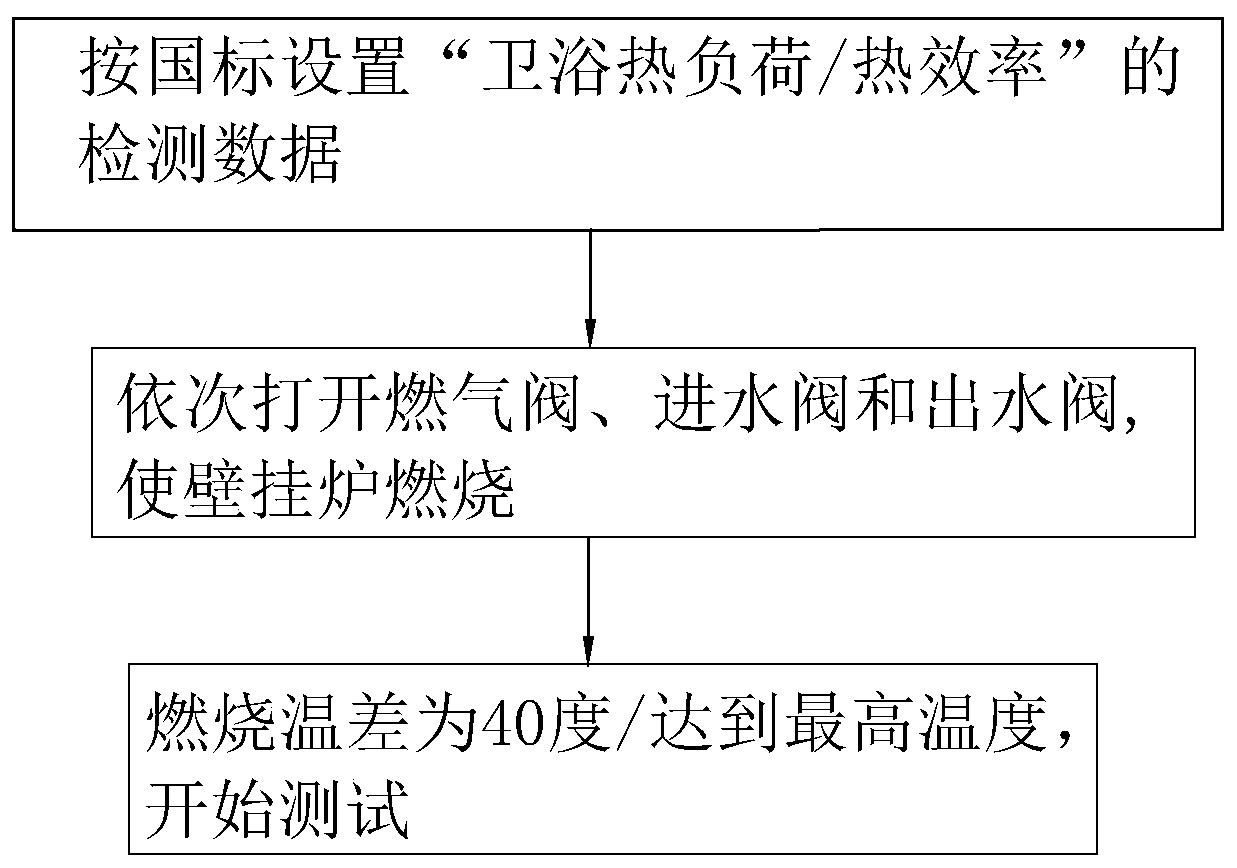

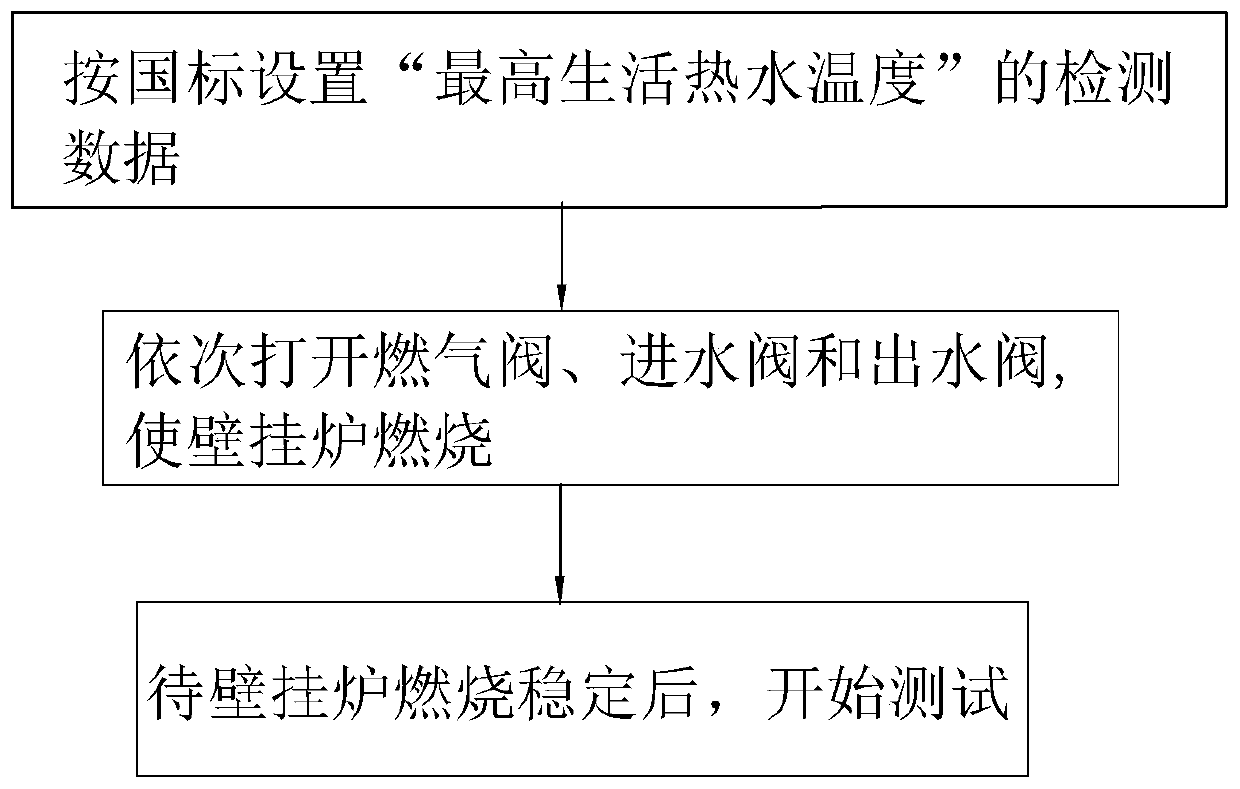

[0059] refer to figure 1 , which is a comprehensive performance testing method and system for a gas-fired heating water heater disclosed in the present invention, and the specific steps are:

[0060] S1: Keep the compressed air in the range of 0.4-0.6MPa, the gas pressure is less than 5000Pa, and the water inlet pressure is greater than or equal to 0.1MPa, so that the drainage facilities of the equipment can drain smoothly, and turn on the compressed air switch, gas switch and water inlet switch;

[0061] S2: Start the test system, start the project, turn on the heating test, perform the automatic water replenishment operation until it is full, and turn off the automatic water replenishment operation;

[0062] S3: Start the operation project, the system automatically performs parameter detection, adjusts the voltage range of the wall-hung boiler and water heater according to the voltage used by the equipment to be tested, and connects the power supply of the equipment to be te...

Embodiment 2

[0158] In one embodiment, a comprehensive performance test system for gas heating and water heaters, including a test module for testing the comprehensive performance of gas heating and water heaters, a storage module for storing comprehensive performance test data for gas heating and water heaters, and a user A query module for querying and exporting the comprehensive performance test data of the gas heating and water heater, and the test module, the storage module and the query module realize the steps of the method for comprehensive performance testing of the gas heating and water heater.

[0159] The specific steps of the test method are:

[0160] S1: Set the initial conditions of the equipment to be tested, make the drainage facilities of the equipment drain smoothly, and turn on the compressed air switch, gas switch and water inlet switch;

[0161] S2: Start the test system, start the project, and turn on the heating test. If the input signal is obtained, the automatic w...

Embodiment 3

[0169] In one embodiment, a storage device is provided, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the computer program, the comprehensive performance of the gas heating water heater is realized. The steps of the test method.

[0170] The specific steps of the test method are:

[0171]S1: Set the initial conditions of the equipment to be tested, make the drainage facilities of the equipment drain smoothly, and turn on the compressed air switch, gas switch and water inlet switch;

[0172] S2: Start the test system, start the project, and turn on the heating test. If the input signal is obtained, the automatic water replenishment operation will be performed; after the water heater is filled with water, a feedback signal will be output. If the feedback signal is obtained, the automatic water replenishment operation will be turned off;

[0173] S3: Start the operation project, the system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com