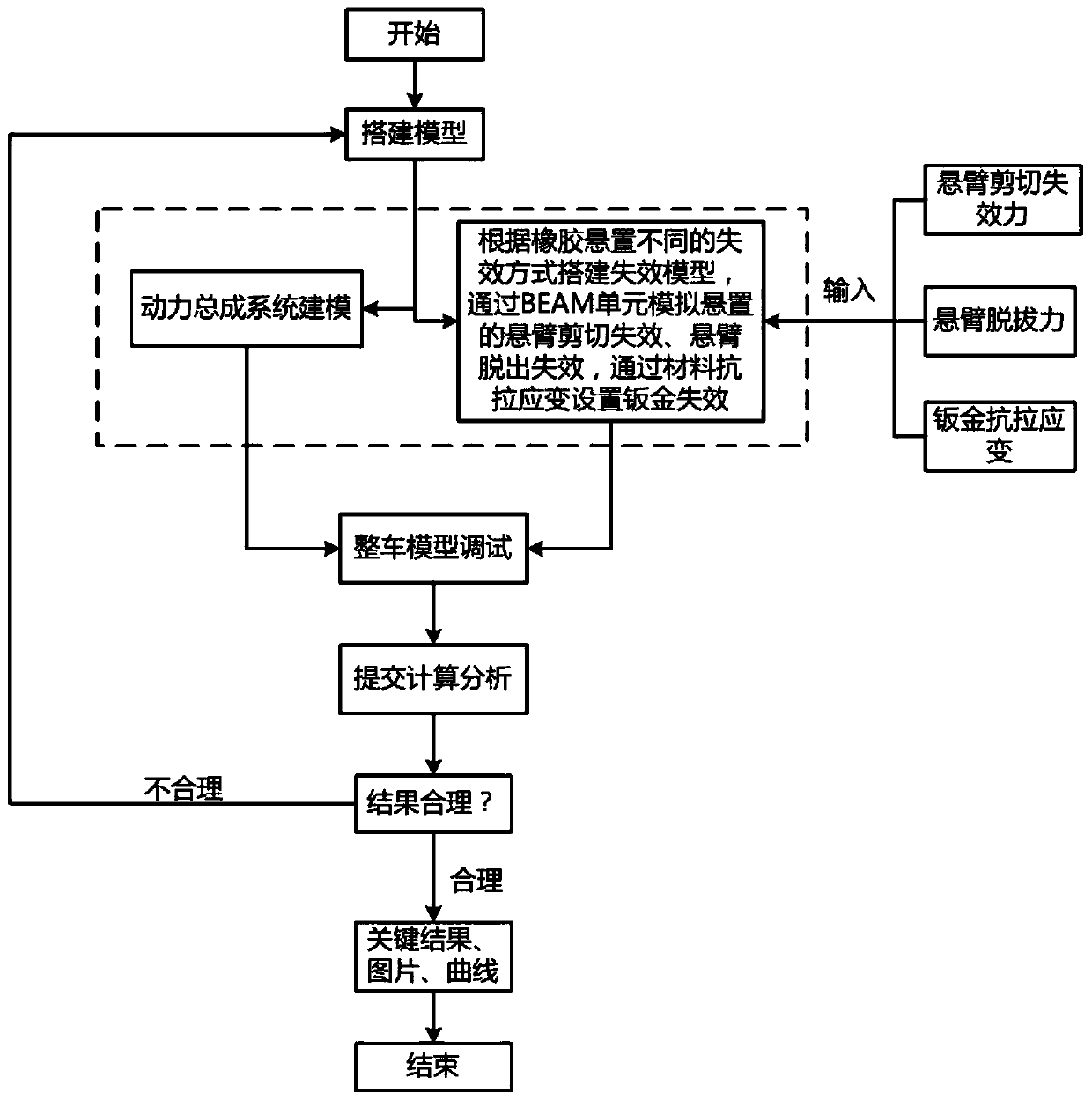

A whole vehicle head-on collision simulation suspension and a failure method thereof

A frontal collision and suspension technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to reflect the collision process, long cycle, failure of simulated powertrain rubber mounts, etc., and achieve error reduction Small, improve the effect of failure problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

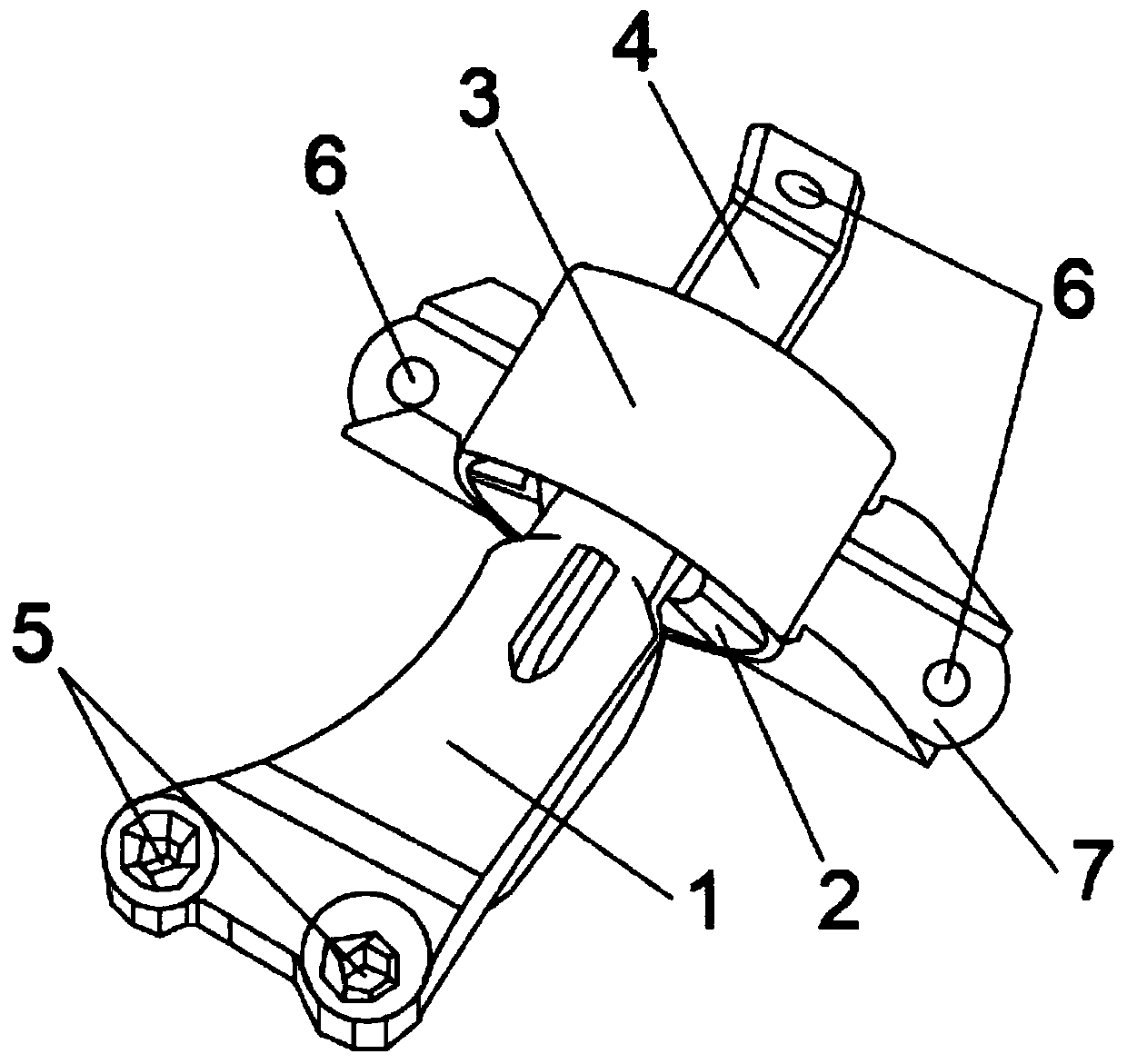

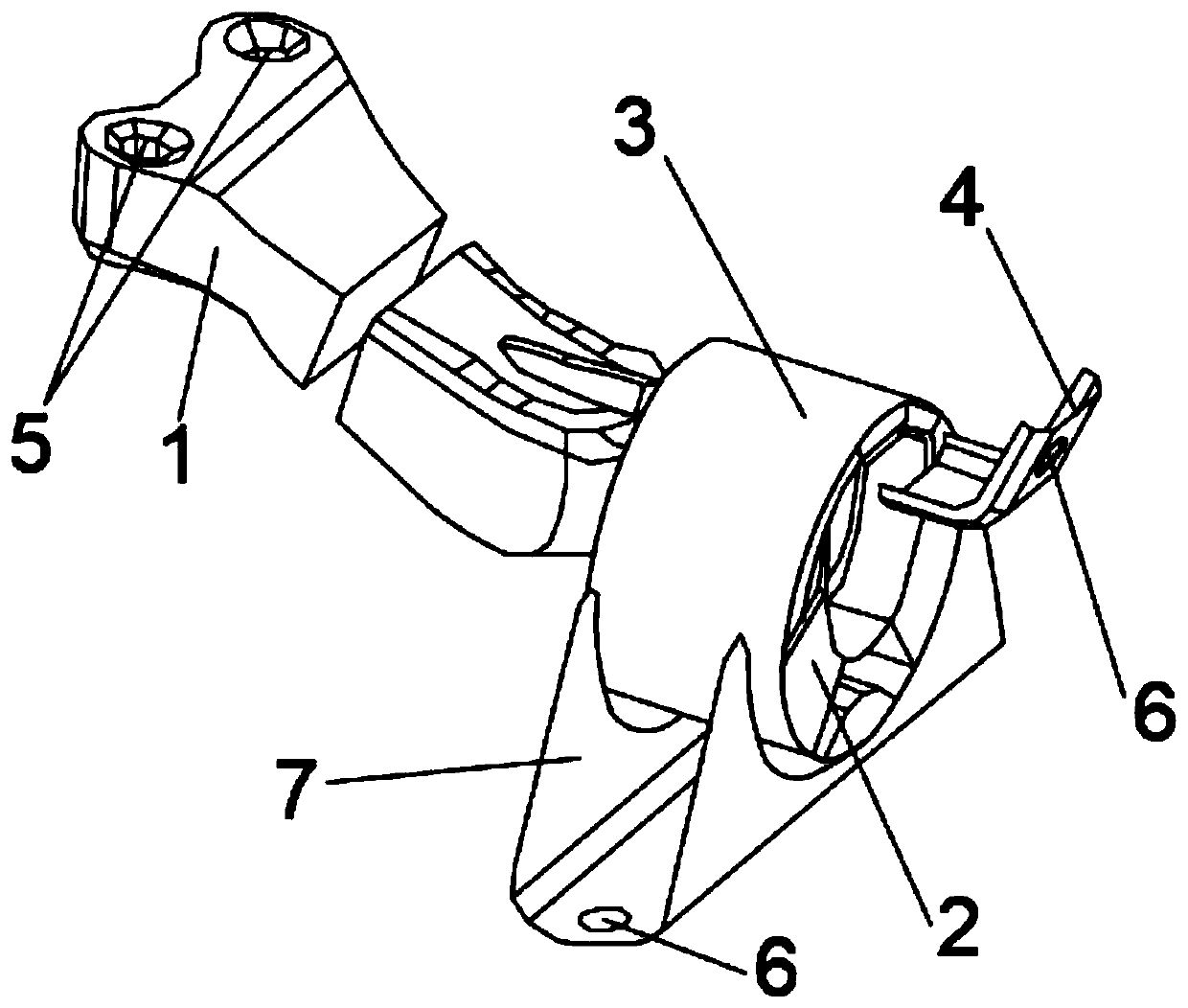

[0029] Such as figure 2 As shown in the present invention, the simulated power assembly rubber suspension in the CAE model of the whole vehicle frontal collision according to the present invention includes a sleeve 3, and also includes a metal casting cantilever 1 sleeved in the sleeve 3, and the The fixing medium between the sleeve 3 and the metal casting cantilever 1 is rubber 2 . The bottom of the sleeve 3 is provided with a second mounting bracket 7, and the metal casting cantilever 1 is fixed with a first mounting bracket 4, the first mounting bracket 4 and the second mounting bracket 7 The ends are all provided with mounting holes 6 on the side of the vehicle body. The metal casting cantilever 1 is provided with a powertrain side mounting hole 5, the number of the powertrain side mounting hole 5 is 2, and the metal casting cantilever 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com