Sterilization system applied to freeze-drying cabinet and sterilization method of sterilization system

A technology of a sterilization system and a sterilization method, which is applied to sanitary equipment, water supply devices, heating and other directions for toilets, can solve the problems of single, unsatisfactory sterilization effect, etc., achieves good safety, improves sterilization effect, eliminates The effect of short bacterial cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

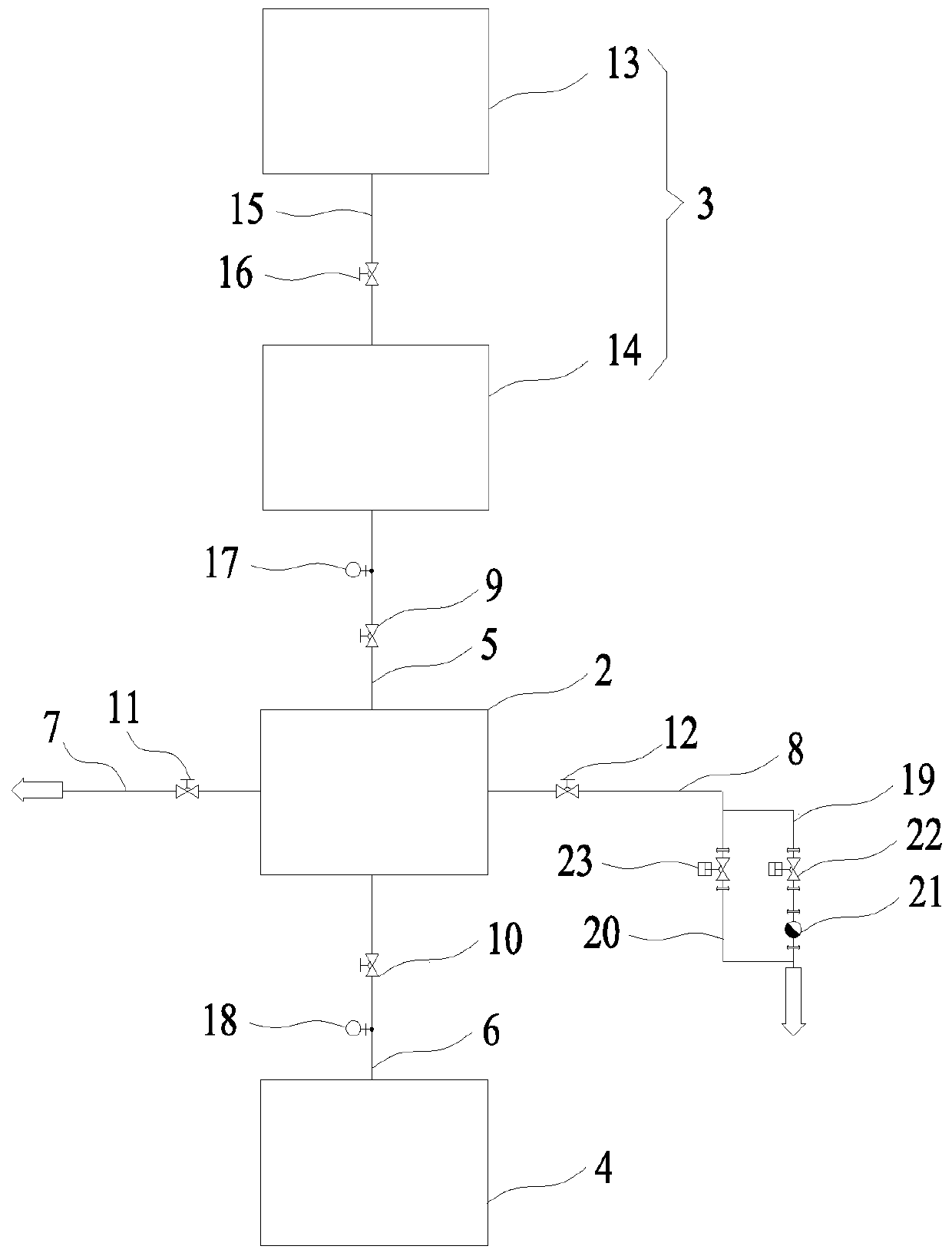

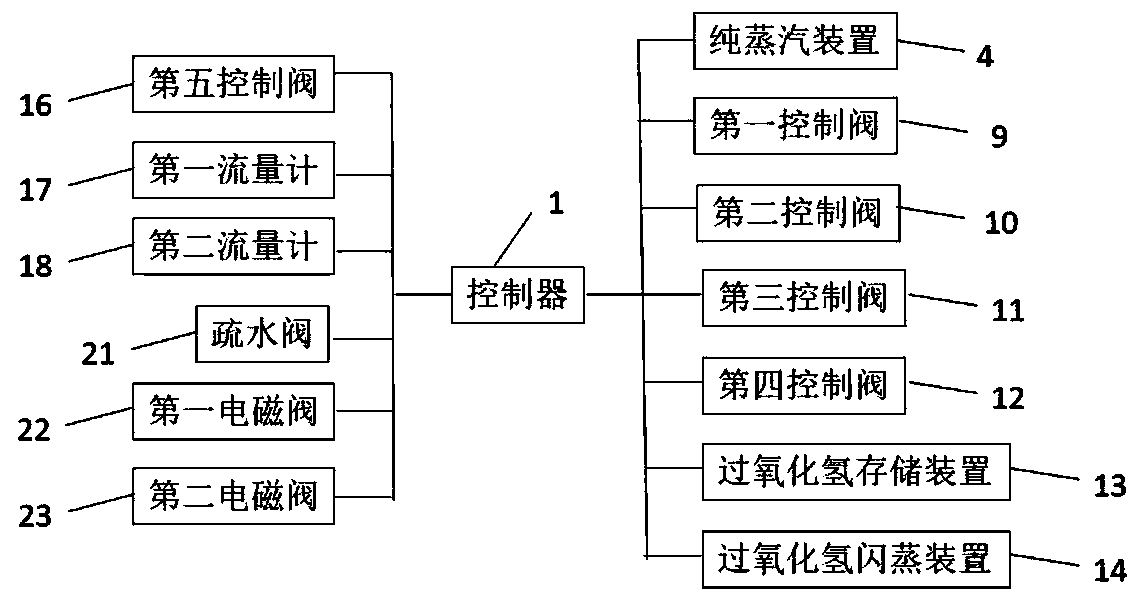

[0024] See also figure 1 with figure 2 , the embodiment of the present invention provides a sterilization system applied to a freeze-drying cabinet, including a controller 1, a hydrogen peroxide device 3 and a pure steam device 4 respectively connected to the freeze-drying cabinet 2. The hydrogen peroxide device 3 is connected to the freeze-drying cabinet 2 through the first steam inlet pipe 5 , and the pure steam device 4 is connected to the freeze-drying cabinet 2 through the second steam inlet pipe 6 . The freeze-drying cabinet 2 is also provided with an exhaust pipe 7 connected to the first steam inlet pipe 5 and a drain pipe 8 connected to the second steam inlet pipe 6 . A first control valve 9 is installed on the first steam inlet pipe 5, a second control valve 10 is installed on the second steam inlet pipe 6, a third control valve 11 is installed on the exhaust pipe 7, and a first control valve 11 is installed on the drain pipe 8. Four control valves 12 . The hydrog...

Embodiment 2

[0032] In the present embodiment, except the concentration of the hydrogen peroxide gas delivered by the hydrogen peroxide device 3, the pressure in the freeze-drying cabinet 2 during the delivery of the hydrogen peroxide gas, the temperature of the steam delivered by the pure steam device 4 and the process of delivering the pure steam Except that the pressure in the middle freeze-drying cabinet 2 is different, others are all the same as in Example 1.

[0033] In this embodiment, the hydrogen peroxide gas delivered by the hydrogen peroxide device 3 has a concentration of 300 ppm. The temperature of the steam delivered by the pure steam device 4 is 130°C.

[0034] In this embodiment, the pressure in the freeze-drying cabinet 2 is maintained at 7.5 Pa during the process of transporting the hydrogen peroxide gas. During the process of transporting pure steam, keep the pressure in the freeze-drying cabinet 2 at 0.15 MPa.

Embodiment 3

[0036] In this embodiment, except that the concentration of the hydrogen peroxide gas delivered by the hydrogen peroxide device 3 and the temperature of the steam delivered by the pure steam device 4 are different, everything else is the same as that of the embodiment 1.

[0037] In this embodiment, the hydrogen peroxide gas delivered by the hydrogen peroxide device 3 has a concentration of 400 ppm. The temperature of the steam delivered by the pure steam device 4 is 145°C.

[0038] In this embodiment, during the process of transporting the hydrogen peroxide gas, the pressure in the freeze-drying cabinet 2 is kept at 10 Pa. During the process of transporting pure steam, keep the pressure in the freeze-drying cabinet 2 at 0.2 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com