A new type of high-efficiency continuous concentrator

A concentrator, high-efficiency technology, applied in solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of unexplained shut-off valve, automatic valve reset of valve body, and water-dispersed expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

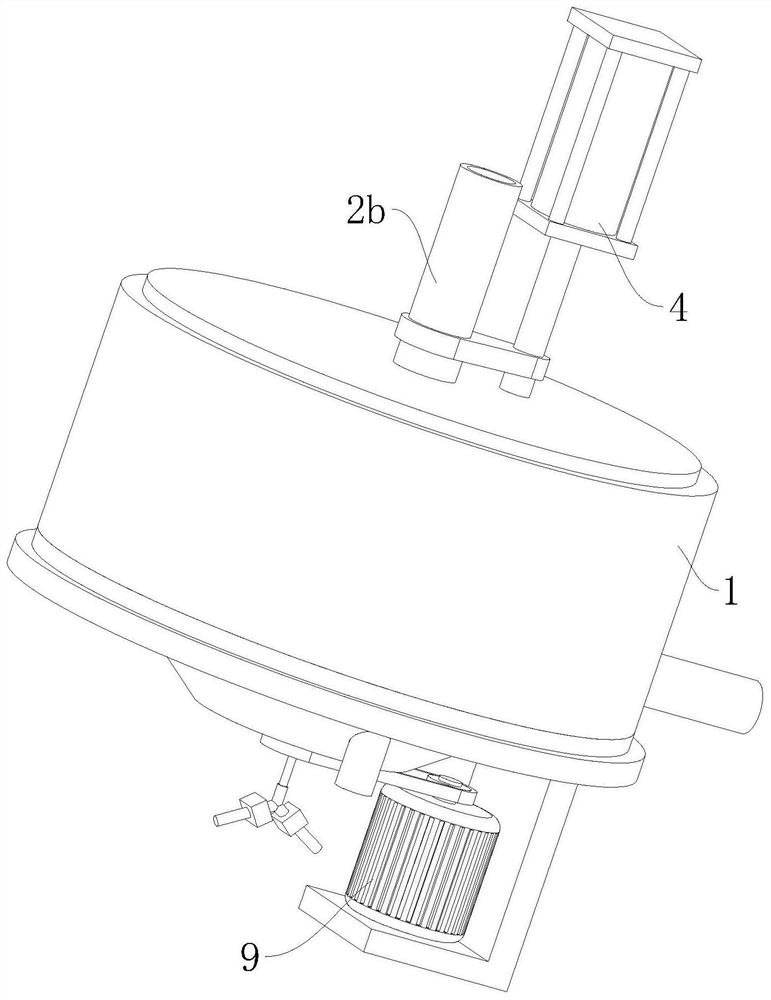

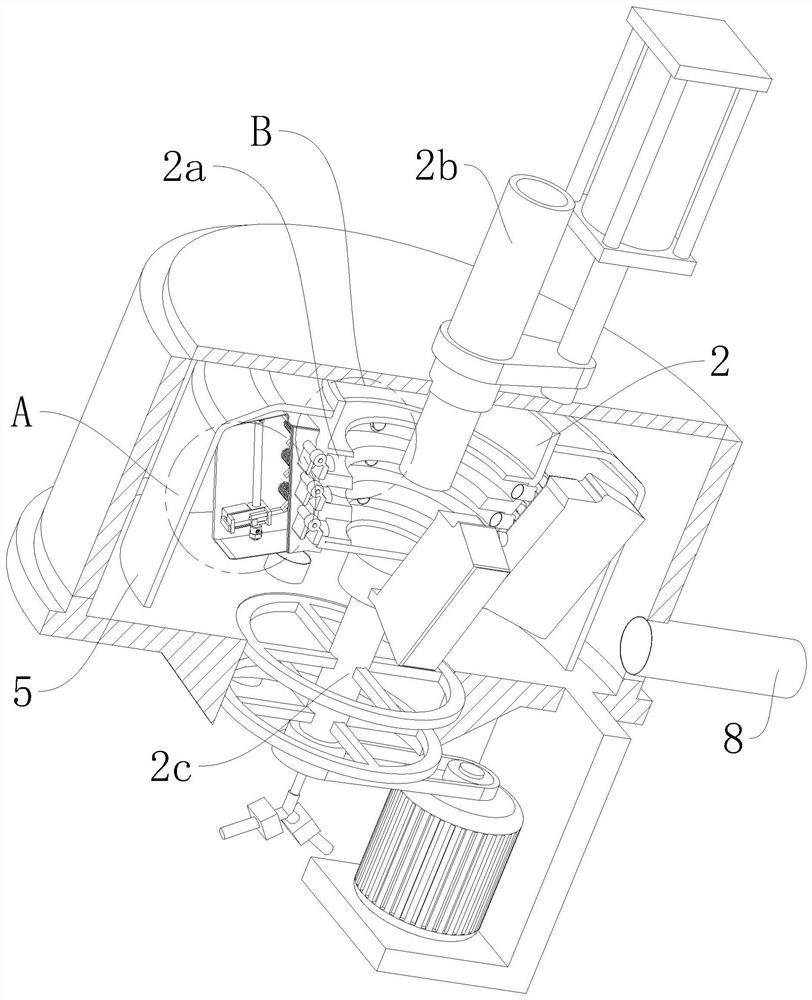

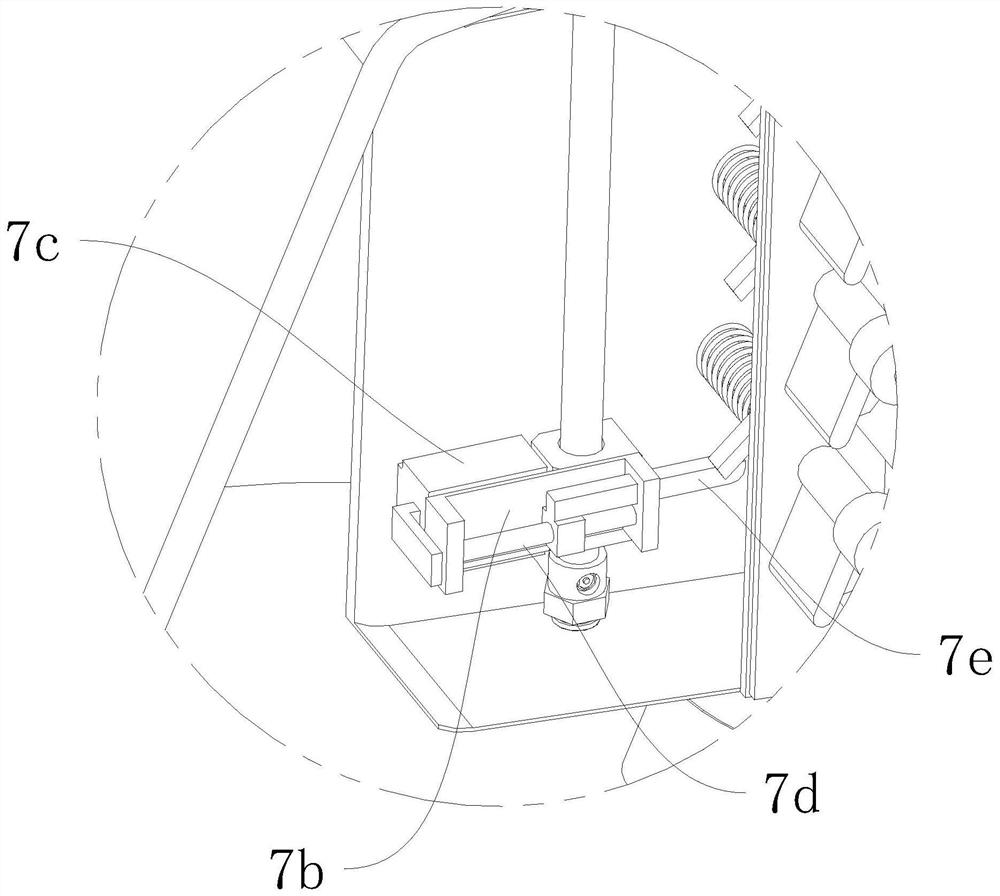

[0038] refer to Figure 1 to Figure 9 A new type of high-efficiency continuous concentrator is shown, including a main cylinder 1, a centrifugal drum 2, a feeding pipe 2b, an air supply system and a concentrate discharge system. The centrifugal drum 2 is installed vertically on the main Inside the cylinder 1, the centrifugal drum 2 is provided with a plurality of separation grooves 2a distributed along the axial interval, and the inner wall of each separation groove 2a is provided with a number of discharge discharge holes distributed equiangularly along the respective circumferential directions. A concentrate discharge pipe 3 is inserted in each discharge port, and a gate is installed at the downstream end of each concentrate discharge pipe 3. The concentrate discharge system includes several centrifugal rotors ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com