A hot melt adhesive film preparation device that reduces volatilization of VOC gas

A technology of hot-melt adhesive film and preparation device, which is applied to flat products, household appliances, and other household appliances, etc., can solve the problems of toxic substances, and achieve the effect of reducing and increasing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

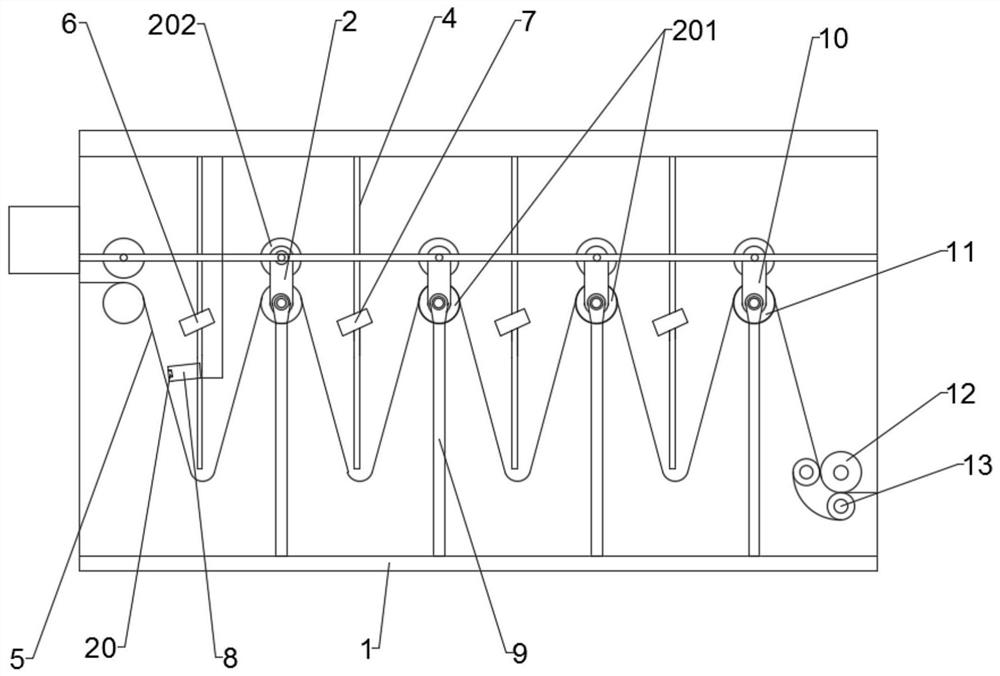

[0048] The Teflon mesh belt 5 is conveyed at a speed of 1.8m / s, the spinning pump is started to spray the die opening 6 to spray the hot melt adhesive raw material, the film spraying seat 8 is sprayed with the modified raw material, and the dosage ratio of the hot melt adhesive raw material and the modified raw material is is 1:0.1.

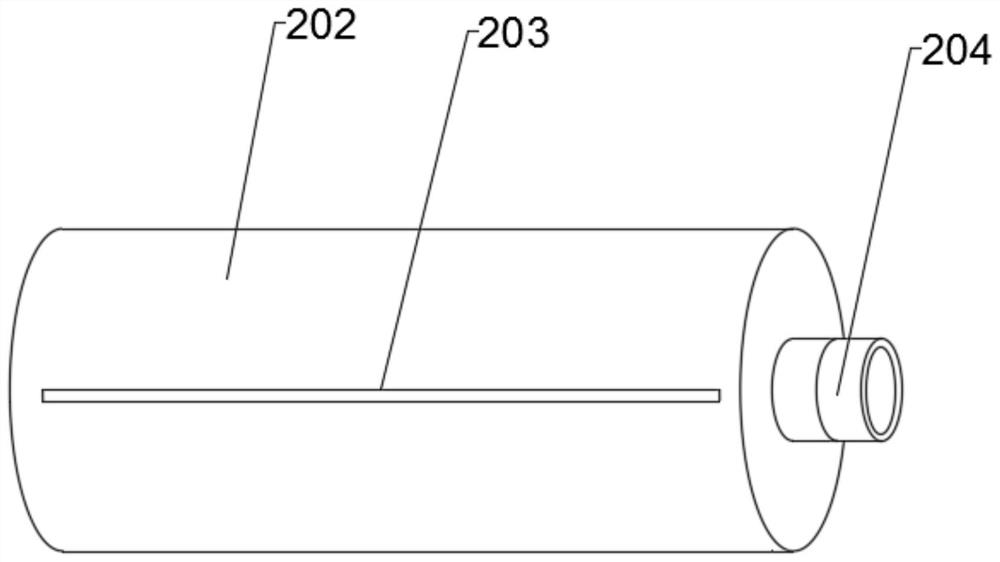

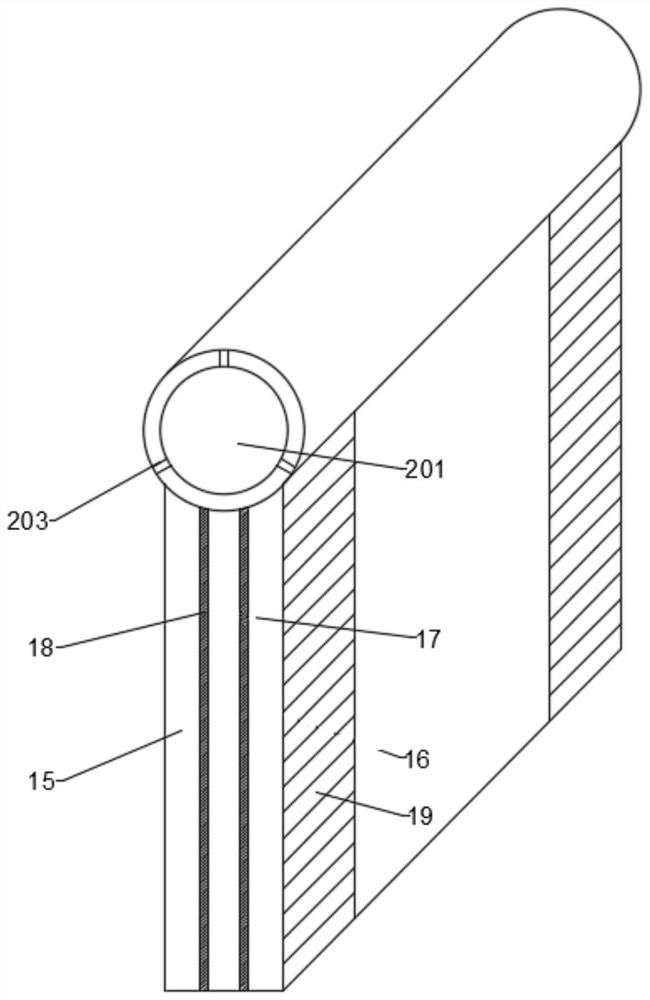

[0049] Start the high-temperature nozzle 7, spray air at 45°C to the upper surface of the Teflon mesh belt 5 (the pressure of the injected fluid is 250Kpa), start the spray slot 203, and the air pressure of the spray slot 203 is 180Kpa; then start the drying plate 15. The air at 10°C is sprayed out, the temperature of the surface of the cooling plate 16 is -18°C, and the airflow chamber 17 is activated at the same time to discharge the gas in the device to the outside of the device.

Embodiment 2

[0051] Transfer the Teflon mesh belt 5 at a rate of 1.5m / s, start the spinning pump to spray the hot melt adhesive material from the die 6, and spray the modified raw material from the surface film nozzle 8. The dosage ratio of the hot melt adhesive raw material and the modified raw material is 1:0.1.

[0052] Start the high temperature nozzle 7, spray air at 40°C on the upper surface of the Teflon mesh belt 5 (the pressure of the injected fluid is 200Kpa), start the spray slot 203, and the air pressure of the spray slot 203 is 150Kpa; then start the drying plate 15. Air at 5°C is sprayed out, the temperature of the surface of the cooling plate 16 is -20°C, and the airflow chamber 17 is activated at the same time to discharge the gas in the device to the outside of the device.

Embodiment 3

[0054] Transfer the Teflon mesh belt 5 at a speed of 2m / s, start the spinning pump to spray the hot melt adhesive raw material from the die 6, and spray the modified raw material from the surface film nozzle 8. The dosage ratio of the hot melt adhesive raw material and the modified raw material is: 1:0.1.

[0055] Start the high-temperature nozzle 7, spray air at 50°C to the upper surface of the Teflon mesh belt 5 (the pressure of the injected fluid is 300Kpa), start the spray slot 203, and the air pressure of the spray slot 203 is 200Kpa; then start the drying plate 15. Air at 15°C is ejected, the temperature of the surface of the cooling plate 16 is -15°C, and the airflow chamber 17 is activated at the same time to discharge the gas in the device to the outside of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com