Hot melt adhesive film preparation device capable of reducing VOC (volatile organic compound) gas volatilization

A technology of hot-melt adhesive film and preparation device, which is applied to flat products, household appliances, and other household appliances, etc., can solve the problems of toxic substances, and achieve the effect of reducing and increasing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

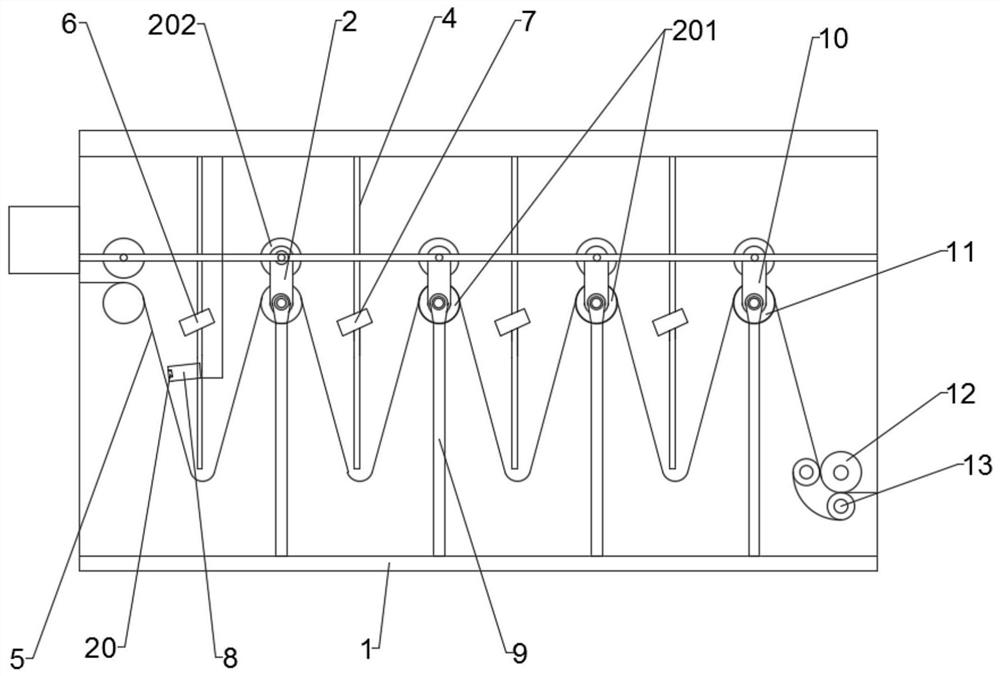

[0048] Convey the Teflon mesh belt 5 at a rate of 1.8m / s, start the spinning pump to spray the hot melt adhesive material at the nozzle 6, and spray the modified raw material at the surface film spray seat 8, the ratio of hot melt adhesive raw material to modified raw material It is 1:0.1.

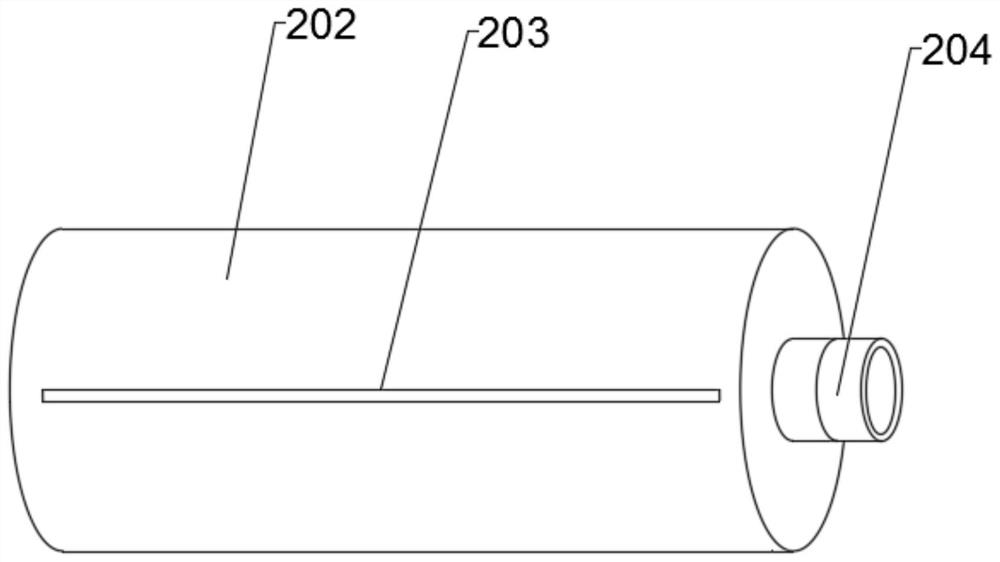

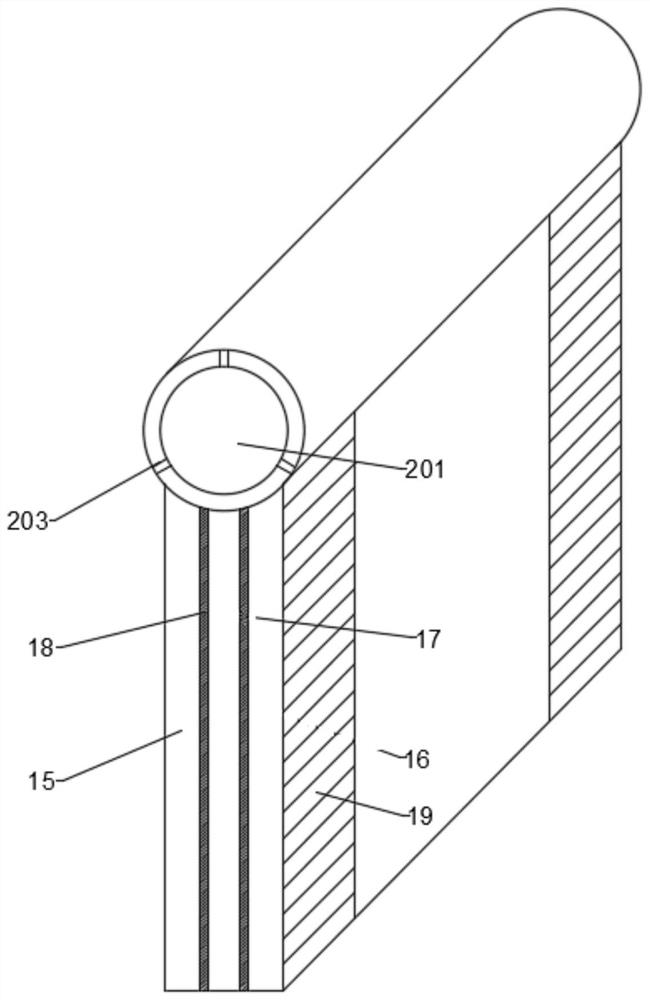

[0049] Start the high-temperature spout 7, spray 45 ℃ of air to the upper surface of the teflon mesh belt 5 (the fluid pressure of ejection is 250Kpa), start the injection slit 203, and the pressure of the injection slit 203 air is 180Kpa; then start the drying plate 15. The air at 10°C is sprayed out, and the surface temperature of the cooling plate 16 is -18°C. At the same time, the air flow chamber 17 is activated to discharge all the gas in the device to the outside of the device.

Embodiment 2

[0051] Convey the Teflon mesh belt 5 at a rate of 1.5m / s, start the spinning pump to spray the hot melt adhesive material at the nozzle 6, and spray the modified raw material at the surface film spray seat 8, the ratio of the amount of the hot melt adhesive raw material to the modified raw material It is 1:0.1.

[0052] Start the high-temperature spout 7, spray 40 ℃ of air to the upper surface of the teflon mesh belt 5 (the jetted fluid pressure is 200Kpa), start the injection slot 203, and the pressure of the injection slot 203 air is 150Kpa; then start the drying plate 15. Spray air at 5°C, the temperature on the surface of the cooling plate 16 is -20°C, and at the same time activate the air flow chamber 17 to discharge all the gas in the device to the outside of the device.

Embodiment 3

[0054] Convey the Teflon mesh belt 5 at a rate of 2m / s, start the spinning pump injection die mouth 6 to spray the hot melt adhesive raw material, and the surface film spray seat 8 spray the modified raw material, and the consumption ratio of the hot melt adhesive raw material and the modified raw material is 1:0.1.

[0055] Start the high-temperature spout 7, spray 50°C of air to the upper surface of the teflon mesh belt 5 (the fluid pressure ejected is 300Kpa), start the injection slot 203, and the pressure of the injection slot 203 air is 200Kpa; then start the drying plate 15. The air at 15°C is sprayed out, and the surface temperature of the cooling plate 16 is -15°C. At the same time, the air flow chamber 17 is activated to discharge all the gas in the device to the outside of the device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com