A flexible loading and unloading method for CNC machine tools using a truss robot

A technology of CNC machine tools and robots, which is applied in the field of metal parts turning, can solve problems that affect the efficiency of processing operations, limited operating space, and reduce equipment compatibility, and achieve the effect of expanding the application range and continuous processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

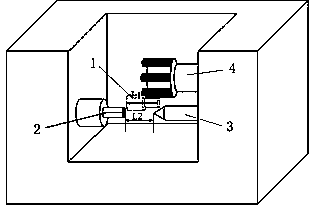

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

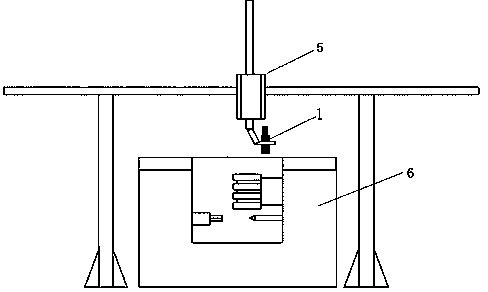

[0026] The invention provides a flexible loading and unloading method of a numerical control machine tool using a truss type robot.

[0027] The method includes steps as follows:

[0028] S1: The operator manually performs loading and unloading, and confirms that the workpiece to be processed can be manually loaded and unloaded;

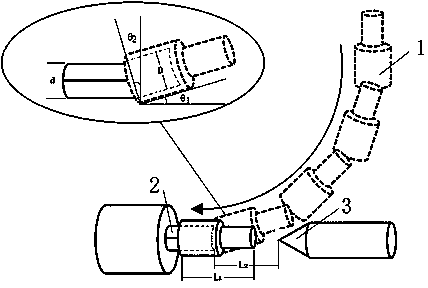

[0029] S2: Obtain the maximum length of the workpiece to be processed and the minimum distance between the loading and unloading interference space in the CNC machine tool through measurement, as well as the matching margin between the inner diameter or outer diameter of the workpiece to be processed and the loosened or clamped state of the chuck of the CNC machine tool, Calculate the feeding angle that can allow loading and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com