Fully-automatic edge grinding device for surgical blades

A surgical blade, fully automatic technology, applied in the direction of grinding drive device, grinding machine, grinding workpiece support, etc., can solve the problems of easy error in grinding edge accuracy, economic burden on enterprises, lengthy operation process, etc., and improve grinding work efficiency. , the effect of maintaining consistency and high synchronization coordination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

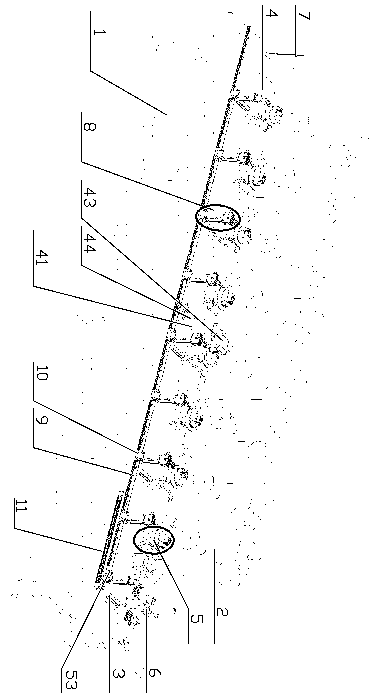

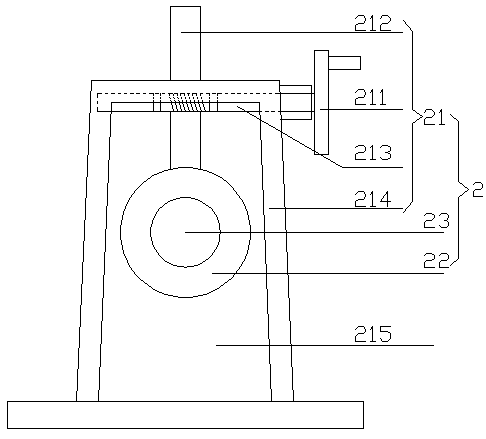

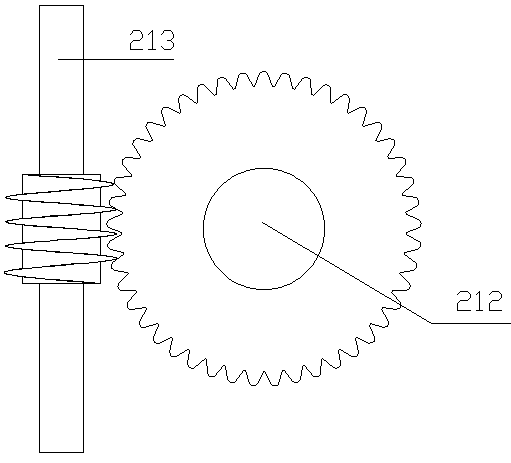

[0042] Embodiment 1: as Figure 1 to Figure 10 The surgical blade automatic grinding device shown includes a workbench 1, and the workbench 1 is provided with a knife sharpening unit, a knife sharpening abutment group, and a blade clamping device group sequentially from back to front, and the knife sharpening unit It consists of multiple sharpening machines 2 and is arranged on the workbench 1 from left to right in a "one" shape. There are multiple supporting slides 3 on the front side of the knife sharpening machine 2, and the top of the supporting slides 3 is front and rear. A support plate 4 is slidingly connected, and the upper surface of the support plate 4 is provided with a sharpening abutment group. A screw moving base 41 is provided, the screw moving base 41 runs through front and back and is threadedly connected with a screw shaft 44, and the screw shaft 44 is driven by a servo motor A43;

[0043] A feeding table 6 is provided on the right side support plate 4 of th...

Embodiment 2

[0073] Embodiment 2: as Figure 9 The shown feeding table 6 can be an automatic feeding device, and the surgical blade 58 in the blade trough 91 is pushed out by the push rod of the common cylinder 90, so as to be grasped by the finger cylinder 83 of ①, when the processes of the 8 stations have been completed , No. ⑨ finger cylinder 83 grabs and places the surgical blade 58 on Figure 10 On the blanking platform 7 shown, the blanking platform 7 is composed of a blanking base 71 and a blanking limit rod 72 positioned on the blanking base 71. The surgical blade 58 is sleeved on the blanking limit rod 72. layer overlay. The common cylinder model used here is: MAL25X100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com