Automatic docking device and method for right angle coordinate flexibility non-contact type connector

An automatic docking and non-contact technology, applied in aircraft, motor vehicles, transportation and packaging, etc., can solve the problems of difficult manual docking of connectors, high labor intensity, poor safety, etc., and achieve simple structure, high degree of automation, The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

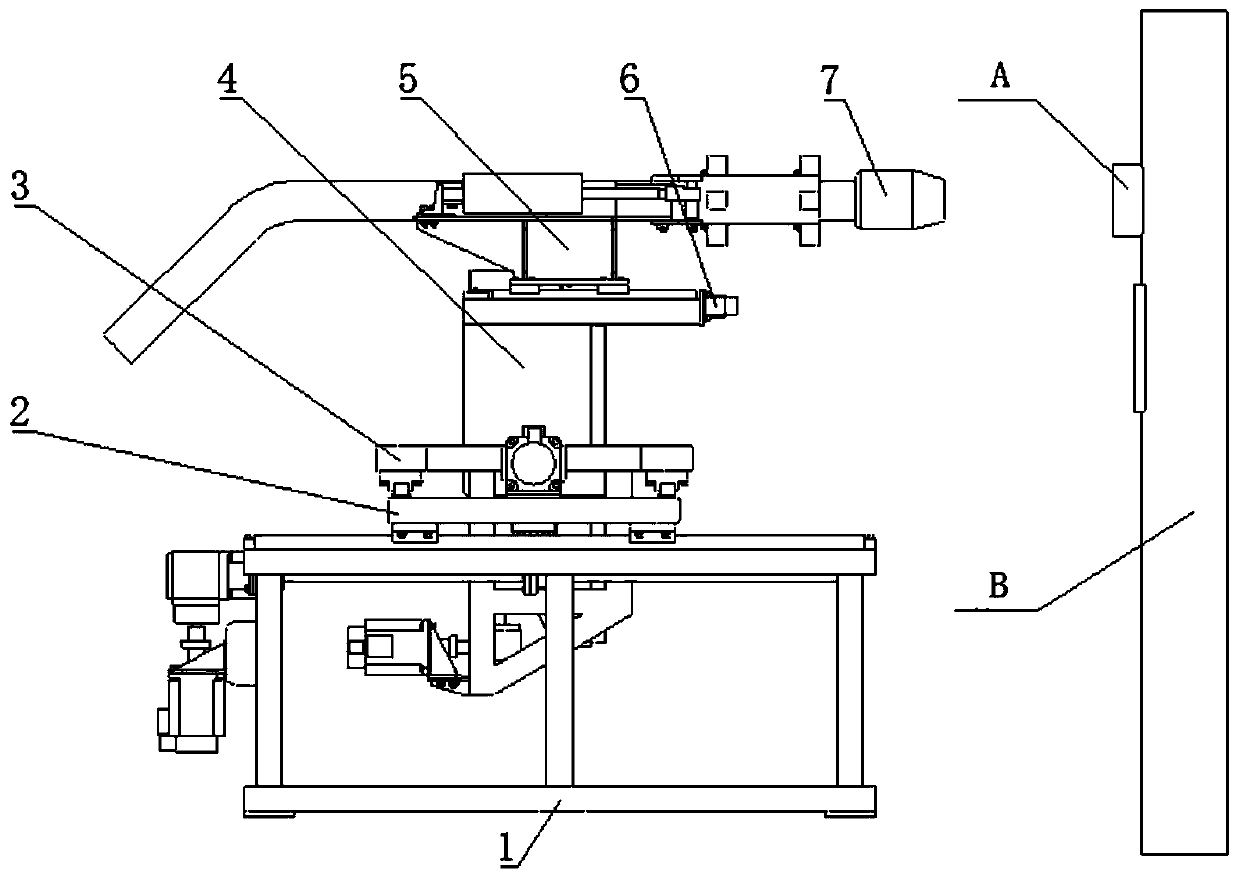

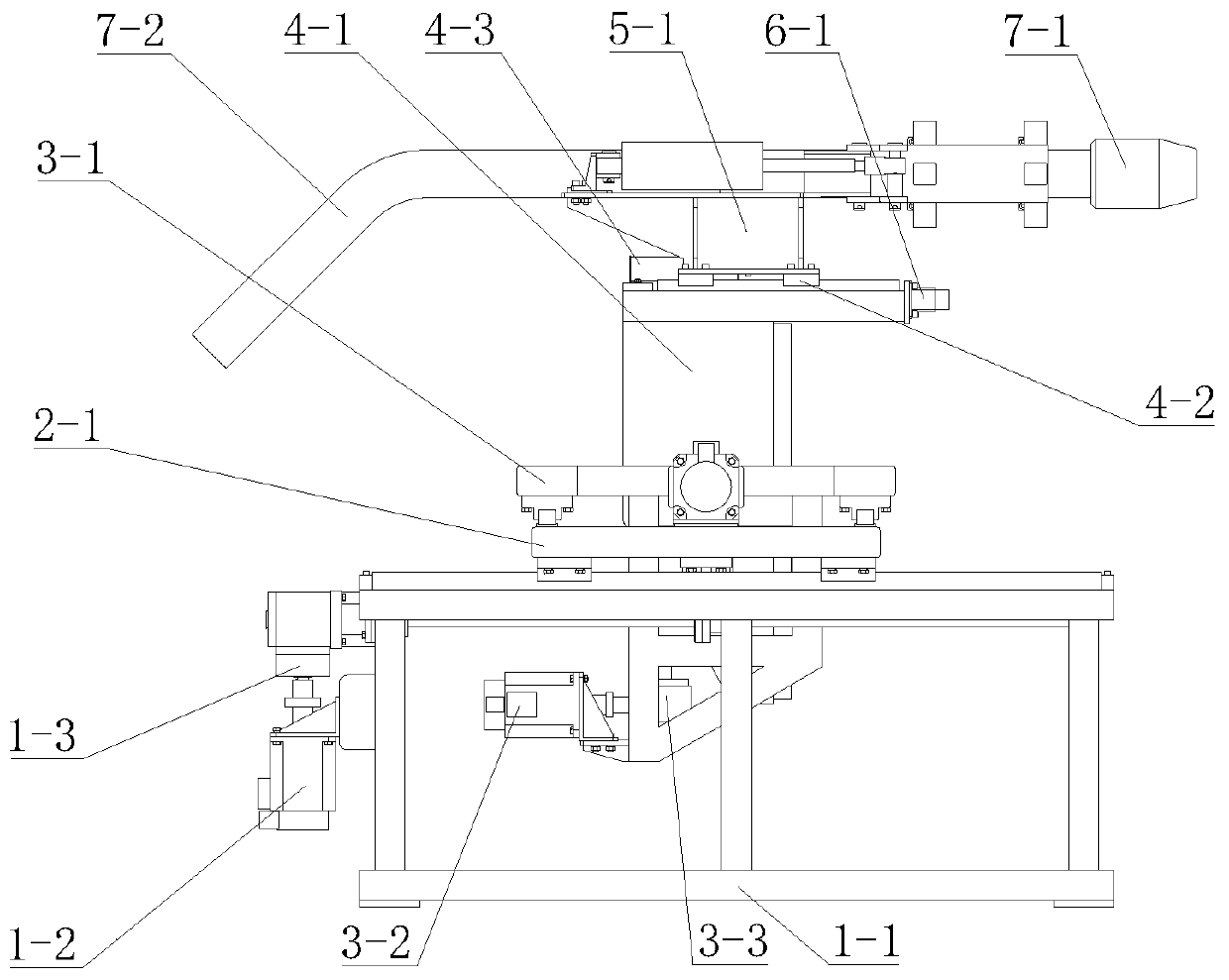

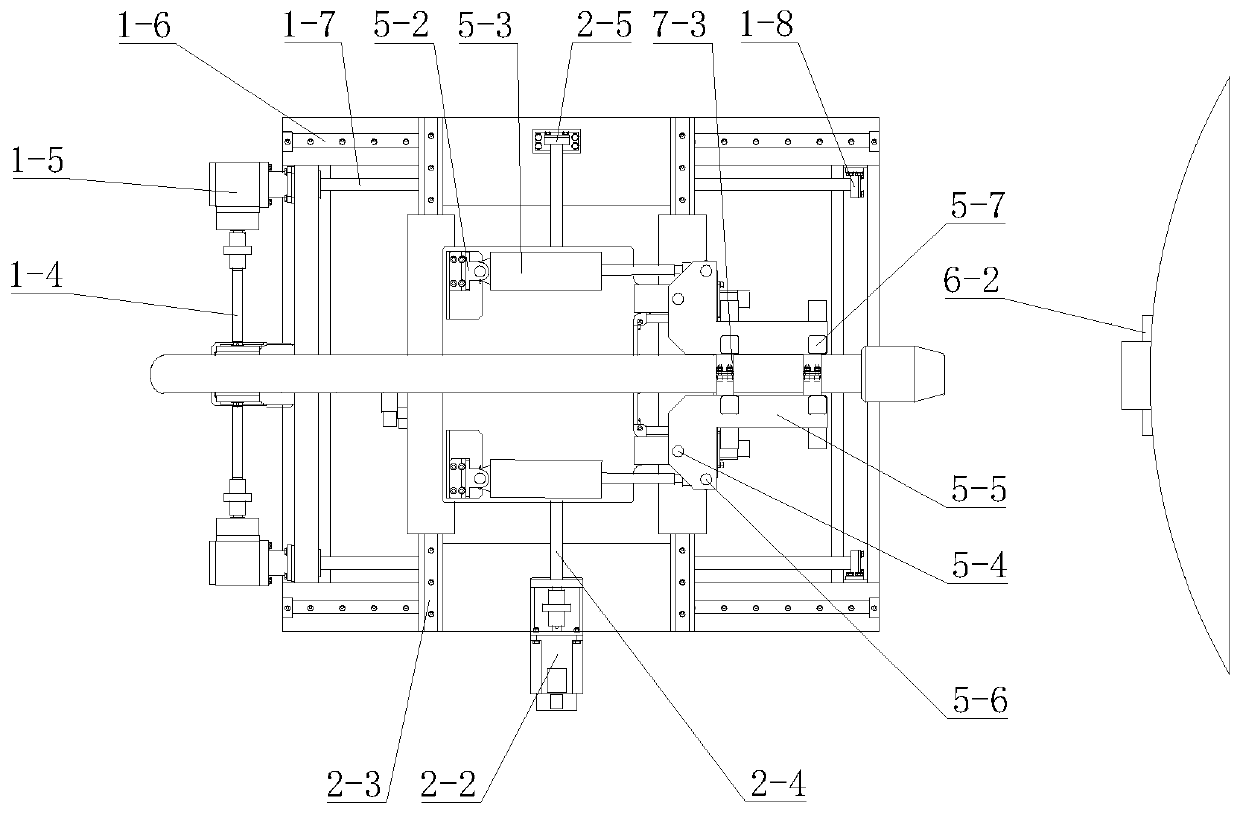

[0031] Such as Figure 1-4 As shown, a Cartesian coordinate flexible non-contact connector automatic docking device of the present invention includes a base 1, an advance and retreat seat 2, a traverse seat 3, a lifting seat 4, a flexible clamping propulsion mechanism 5, a non-contact detection system 6 and a connector Component7.

[0032] The base 1 includes a base frame 1-1, and the upper and rear ends of the base frame 1-1 are equipped with an advancing and retreating AC servo motor 1-2, a double output shaft reducer 1-3 and two pair of right angle reducers 1-5. Two advance and retreat guide rail pairs 1-6 and support bases 1-8 are installed on the top of the base frame 1-1. 8 on. The forward and backward AC servo motor 1-2 is connected with the forward and backward screw pair 1-7 through the double output shaft reducer 1-3, the transmission shaft 1-4, the right angle reducer 1-5, and the forward and backward AC servo motor 1-2 drives Advance and retreat lead screw pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com