Six-suspension-pole internal and external double-rotor type magnetic suspension slice switch reluctance motor

A dual-rotor, thin-film switch technology, applied in AC motor control, magnetic circuit, electric components, etc., can solve the problems of reducing suspension force density and torque density, torque tooth occupancy, large radial space, etc. The effect of torque and suspension force, low cost and power consumption, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

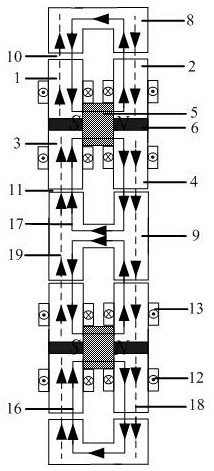

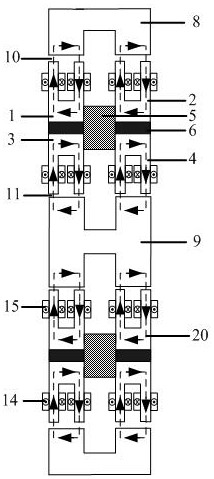

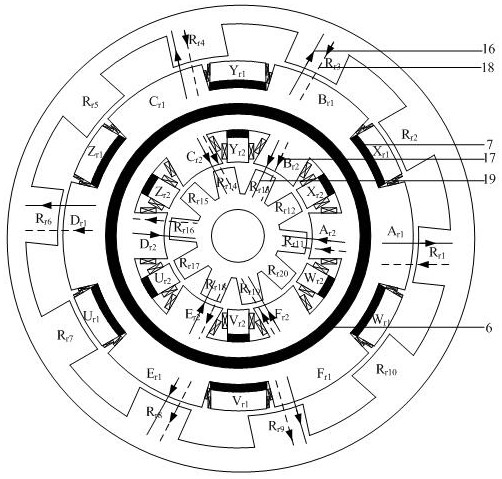

[0023] Specific implementation methods such as Figure 1-4 As shown, a magnetic levitation switched reluctance motor with six levitation poles and inner and outer double rotors includes a stator, an inner rotor, an outer rotor, and a rotating shaft. The stator includes a left motor stator core, a right motor stator core, a permanent magnet ring 5 and two magnetic isolation aluminum rings 6 . The left motor stator core and the right motor stator core are respectively divided into left outer motor stator core 1, left inner motor stator core 3, right outer motor stator core 2, right inner motor stator core 4 by their corresponding magnetic isolation aluminum rings 6, left The outer circumference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com