A carding roller for a rotor spinning device, and the rotor spinning device

A technology of air spinning and opening roller, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, etc. It can solve the problems of large flange space requirements, complex connection release, etc., and achieve saving Effects of space, simplification of manufacture, and simple support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following description of the figures, identical and / or at least similar features in the various figures are identified with the same reference numerals. Each feature, its technical solution and / or operating principle is usually only described in detail when it is first mentioned. If each feature is not described in detail again, its technical solution and / or working principle is equivalent to the technical solution and working principle of the features already described.

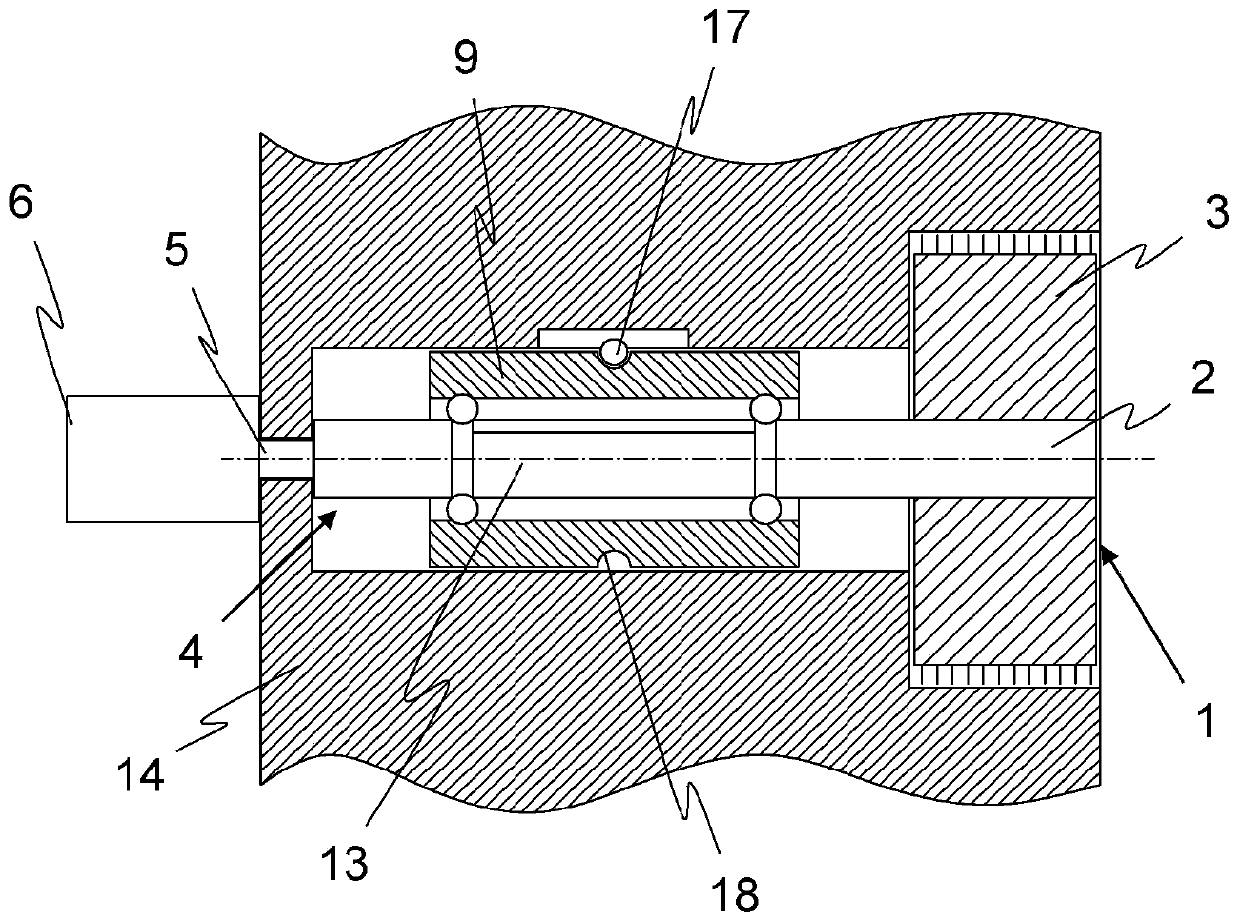

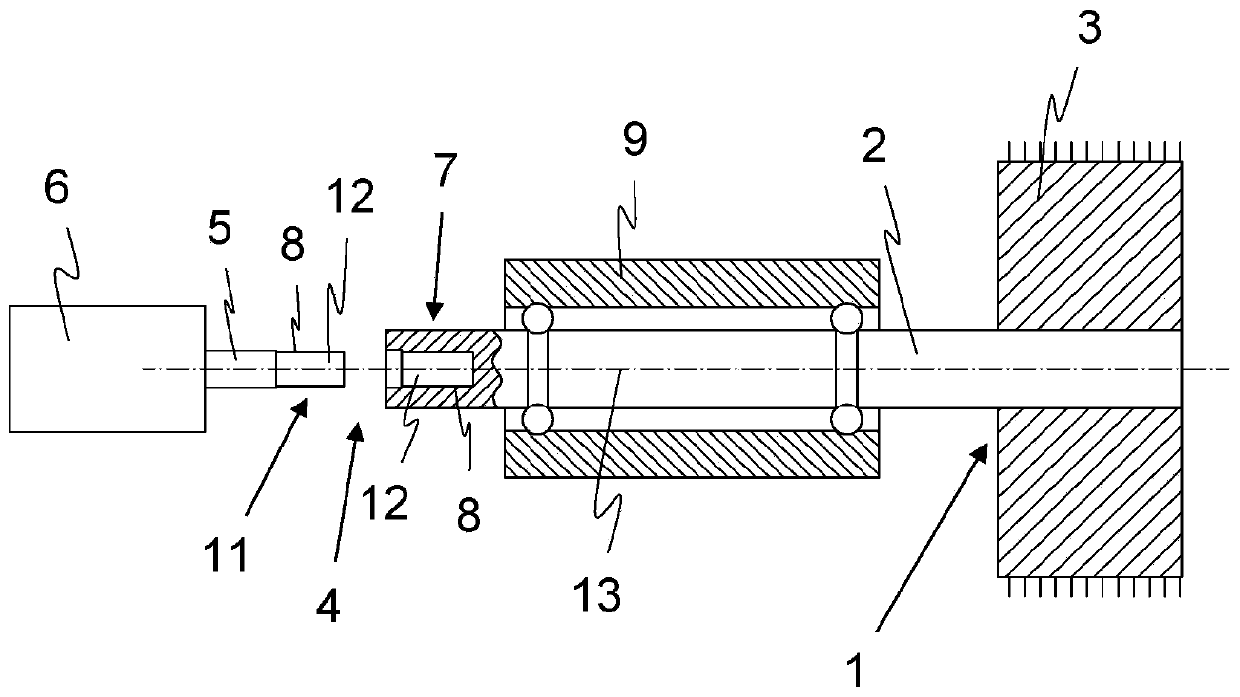

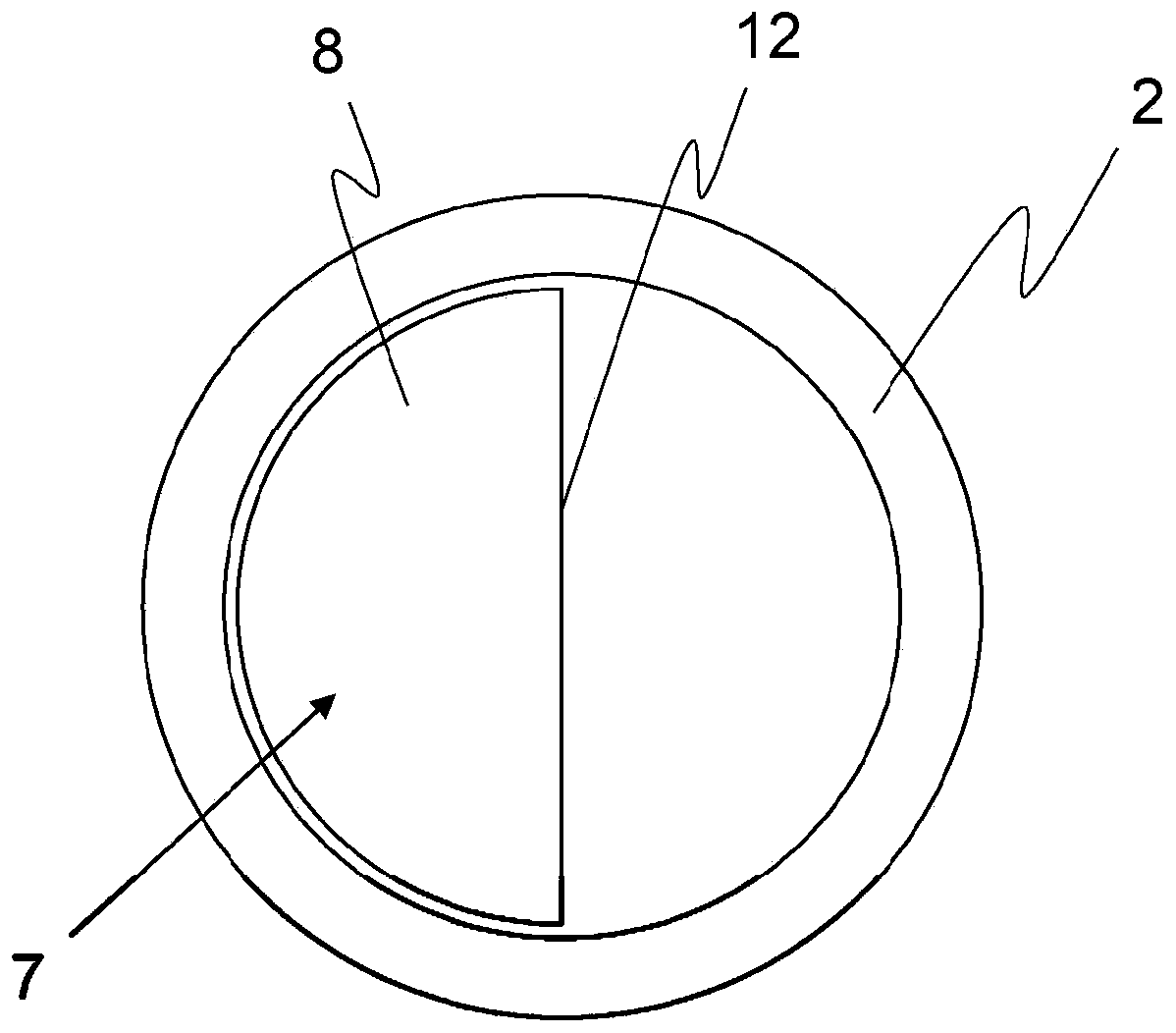

[0040] Such as Figure 1a As shown, the opening roller 1 , which consists of a drive shaft 2 and a roll body 3 , is connected via a coupling device 4 to an output shaft 5 of a drive, which is designed here as an electrically independent drive 6 . The drive shaft 2 and the driven shaft 5 have a common axis of rotation 13 . The coupling device 4 is formed by a coupling element 7 on the side of the opening roller 1 and by a coupling 11 on the side of the independent drive 6 (see Figure 1b ). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com