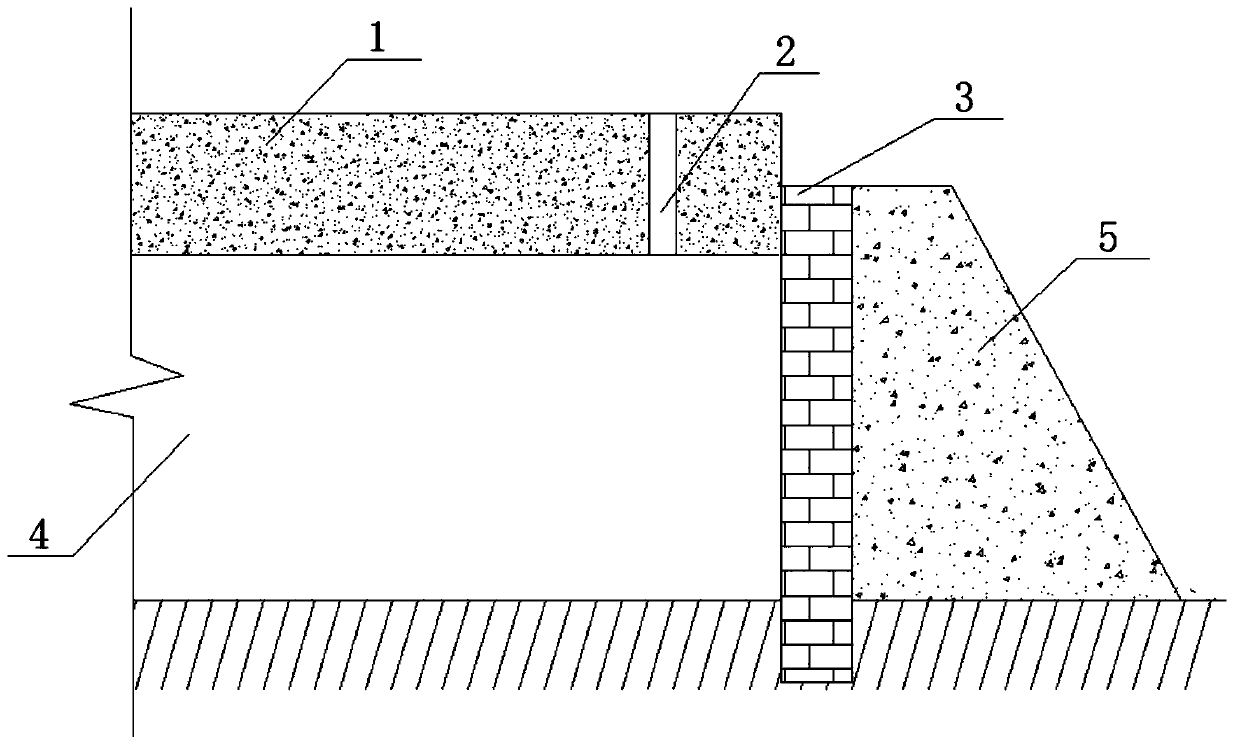

Construction method for filling cave dwelling with self-compacting cement soil

A construction method and cement-soil technology, applied in filling, infrastructure engineering, construction, etc., can solve problems such as high construction cost, complicated construction process, and difficulty in guaranteeing the quality of backfilling in cave dwelling treatment engineering, and achieve high construction cost and low cost. Inexpensive, easy-to-modulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the self-compacting cement soil of the present invention, the cement is an inorganic gelling material, and the cement soil is diluted with water to increase its fluidity, and the water can be turned into a certain strength cement soil after natural evaporation.

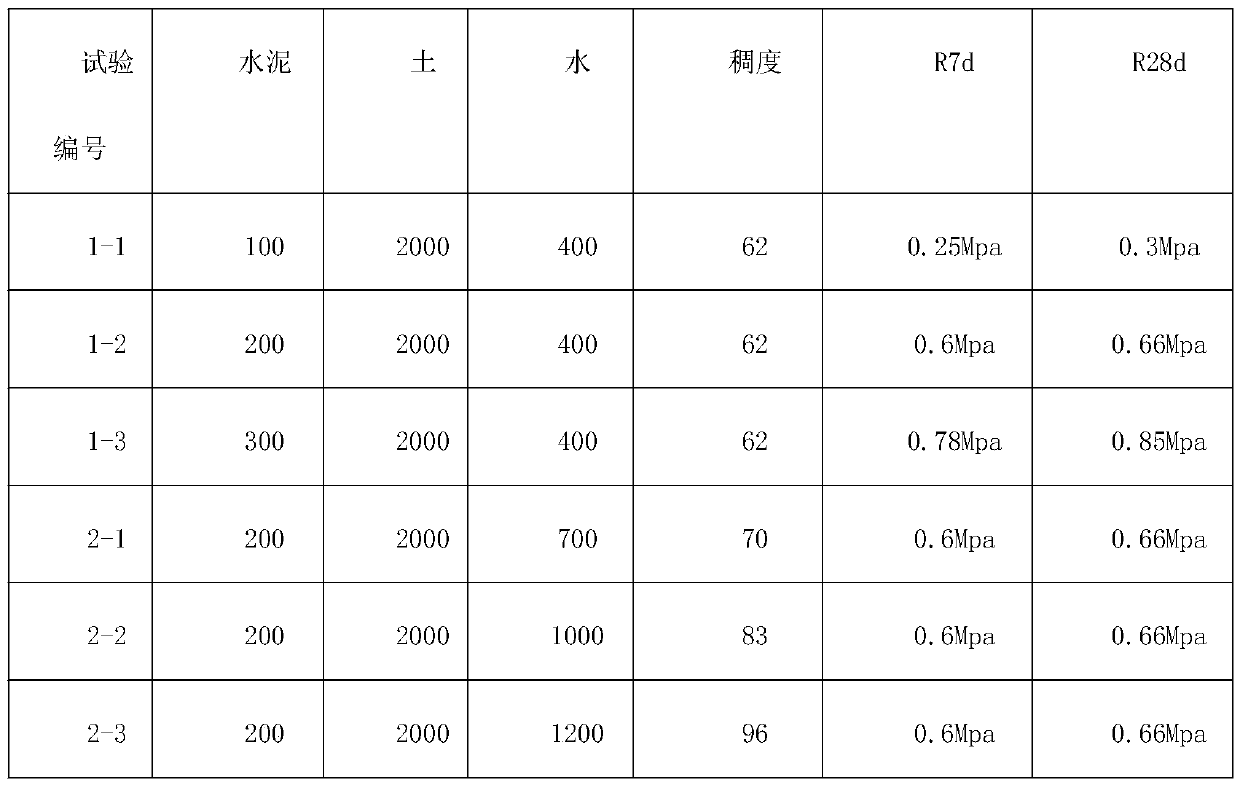

[0032] In order to produce cement soil with appropriate strength, several sets of mix ratios are designed according to the site conditions, materials are configured according to the mix ratio, and the consistency testing equipment is used to test, and 0.7×0.7×0.7 test blocks are made, and the strength is tested after 7 days and 28 days of curing. The following table data is obtained:

[0033]

[0034] The self-tightening cement-soil mix ratio is determined through repeated tests. The cement content is 10%. After the water evaporates, its strength can reach more than 0.6Mpa after testing, which fully meets the strength requirements. The volume mix ratio of cement-soil is cement:soil:water =200:2000:1000 (f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com