Assembly soft steel compound friction damper and assembly method thereof

A compound damping and prefabricated technology, applied in protective buildings/shelters, building components, building types, etc., can solve problems such as single energy consumption mechanism, high shape requirements, and ineffectiveness, and achieve low production cost, The effect of simple form and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

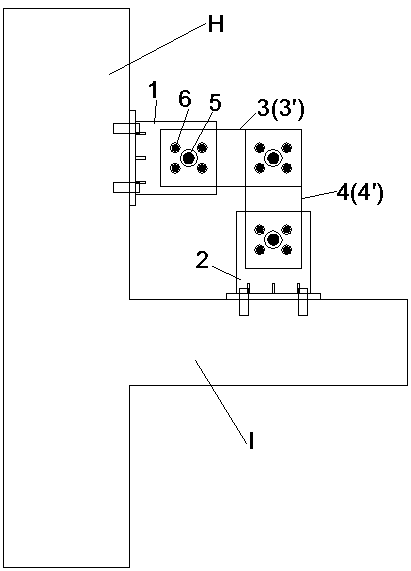

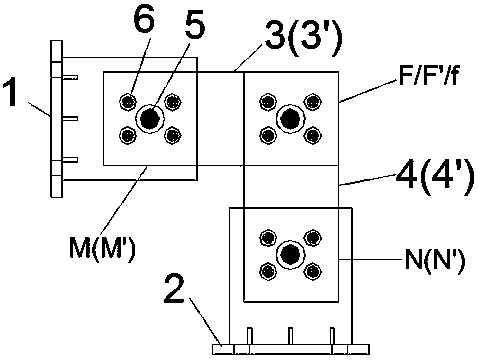

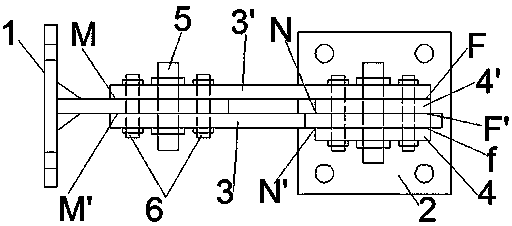

[0027] Such as Figure 1-7 As shown, the present invention proposes an assembled mild steel-friction composite damper, comprising a first connecting plate 1, a second connecting plate 2, a first friction plate 3, a second friction plate 4, high-strength bolts 5 and mild steel Stick 6.

[0028] The first connecting plate 1 is composed of a bottom plate 7 and a web 8, and there is a stiffening rib 9 between the bottom plate and the web to increase the strength. The bottom plate is provided with a bottom plate bolt hole 16, and the high strength bolt passes through the bottom plate bolt hole 16 and The column H is fixed; both sides of the web 8 are sandblasted; the second connecting plate 2 has the same shape and size as the first connecting plate, and is fixed to the beam 1 through the bolt holes 16 of the bottom plate by high-strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com