Thermal expansion valve

A technology of thermal expansion valve and concave part, which is applied in the direction of lighting and heating equipment, fluid circulation arrangement, refrigeration components, etc., and can solve problems such as difficulty in stably controlling the flow rate and affecting the lift of the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Thermal expansion valve comprises air box head, valve body and valve stem 20 (referring to Figure 15 ), the air box head and the valve body are fixedly arranged, and the air box head and the valve stem are arranged in cooperation, and the thermal expansion valve can be used for throttling the fluid flow in the air conditioning system.

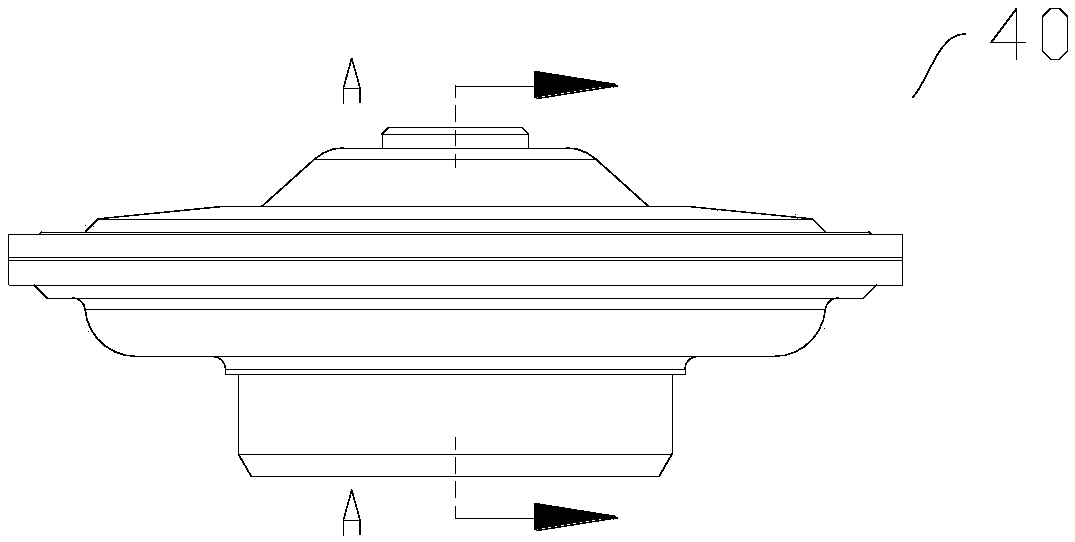

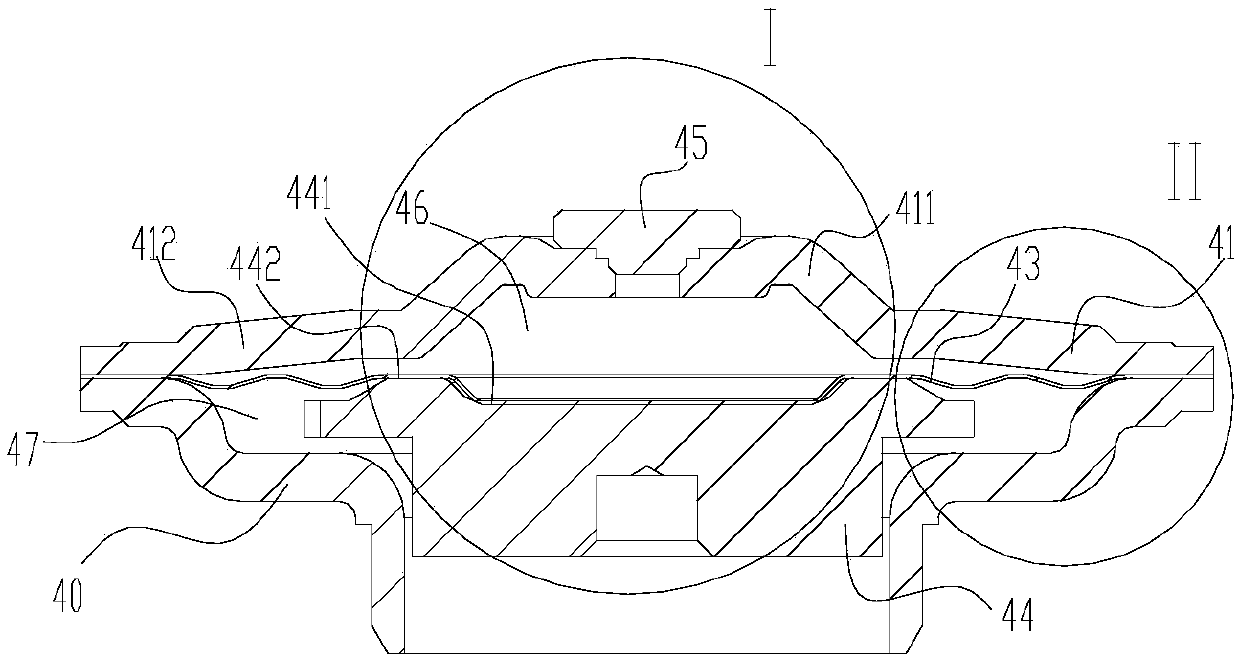

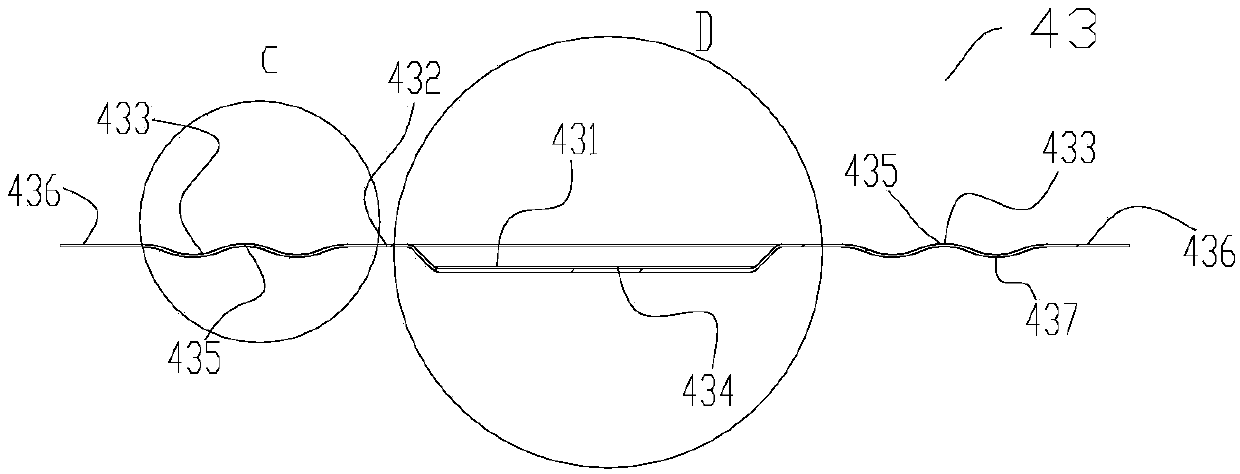

[0024] refer to figure 1 and figure 2 , figure 1 A schematic structural view of the air box head 40 is shown, figure 2 for figure 1 As shown in the schematic cross-sectional view of the A-A direction, the air box head 40 includes an air box cover 41, an air box seat 42, a diaphragm 43, a transmission piece 44 and a sealing plug 45, and the diaphragm 43 is located between the air box cover 41 and the air box seat 42 and the air box cover 41 and the air box seat 42 are fixedly arranged, such as by welding, the inside of the air box head 40 includes a closed chamber 46 and a pressure equalizing chamber 47, and a diaphragm 43 separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com