Walnut cookie roller-marking machine

A technology of roller printing machine and peach cake, which is applied to the structural parts of mixing/kneading machinery, dough anti-sticking, baking, etc. The effect of reducing stickiness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

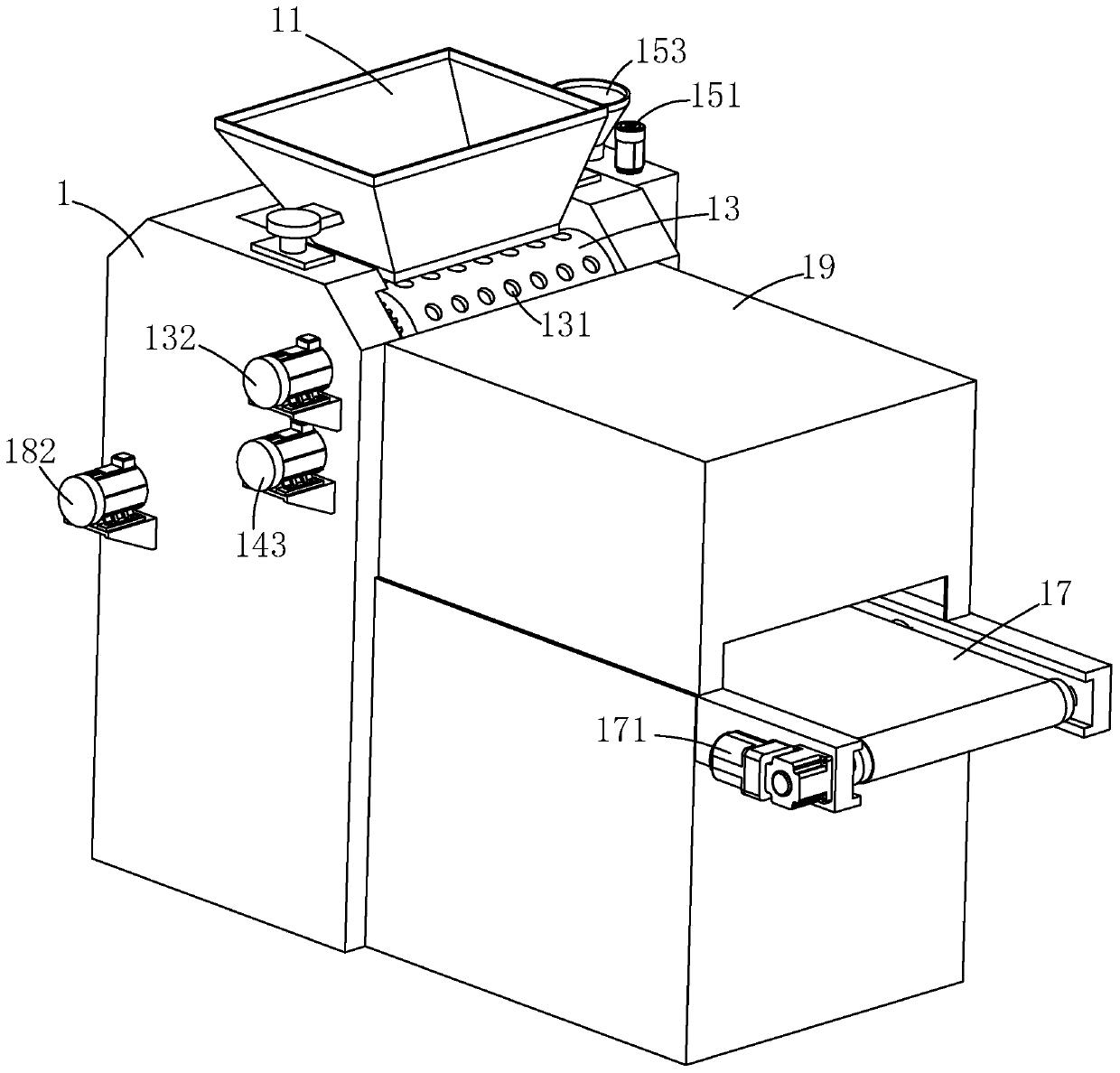

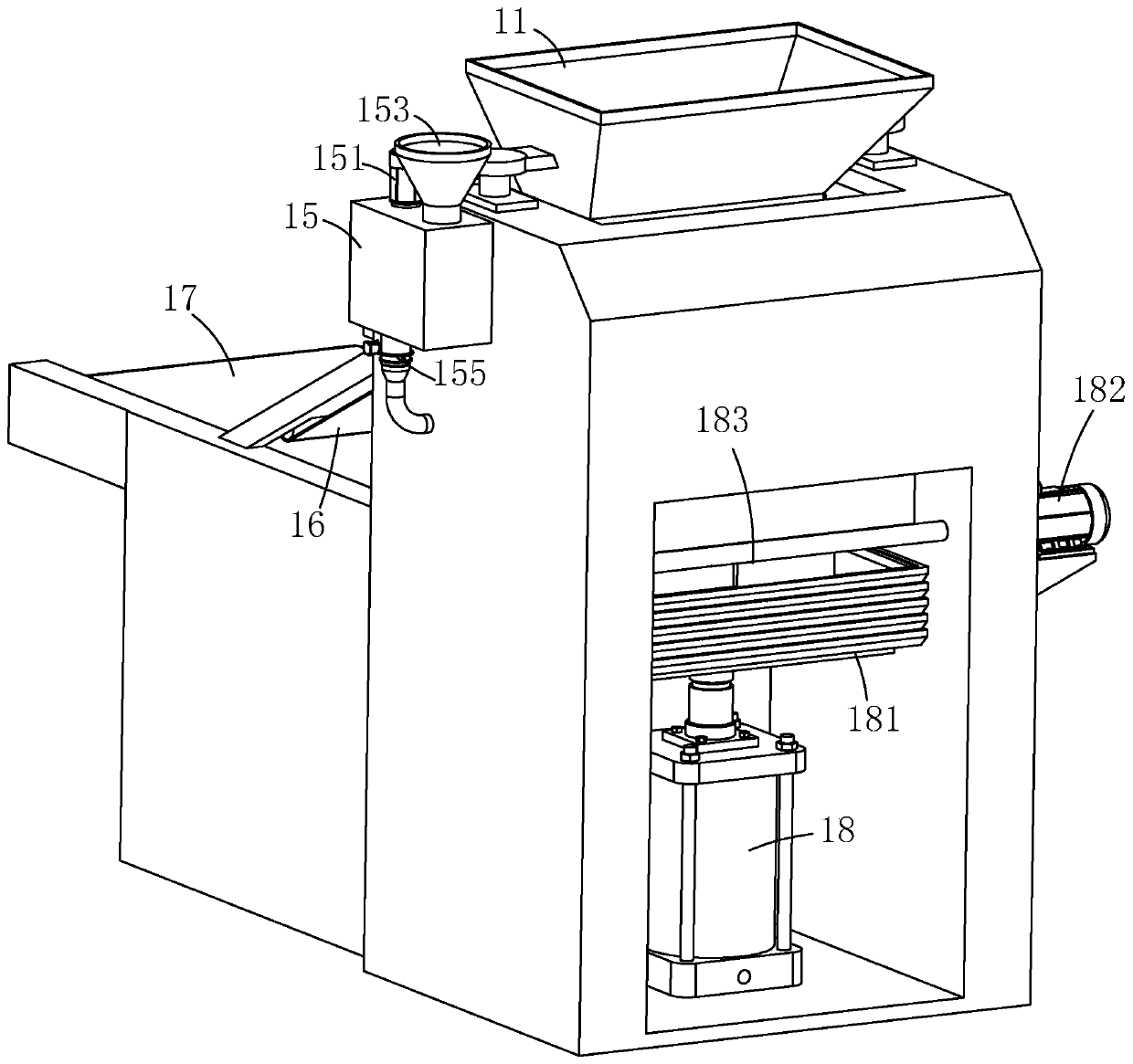

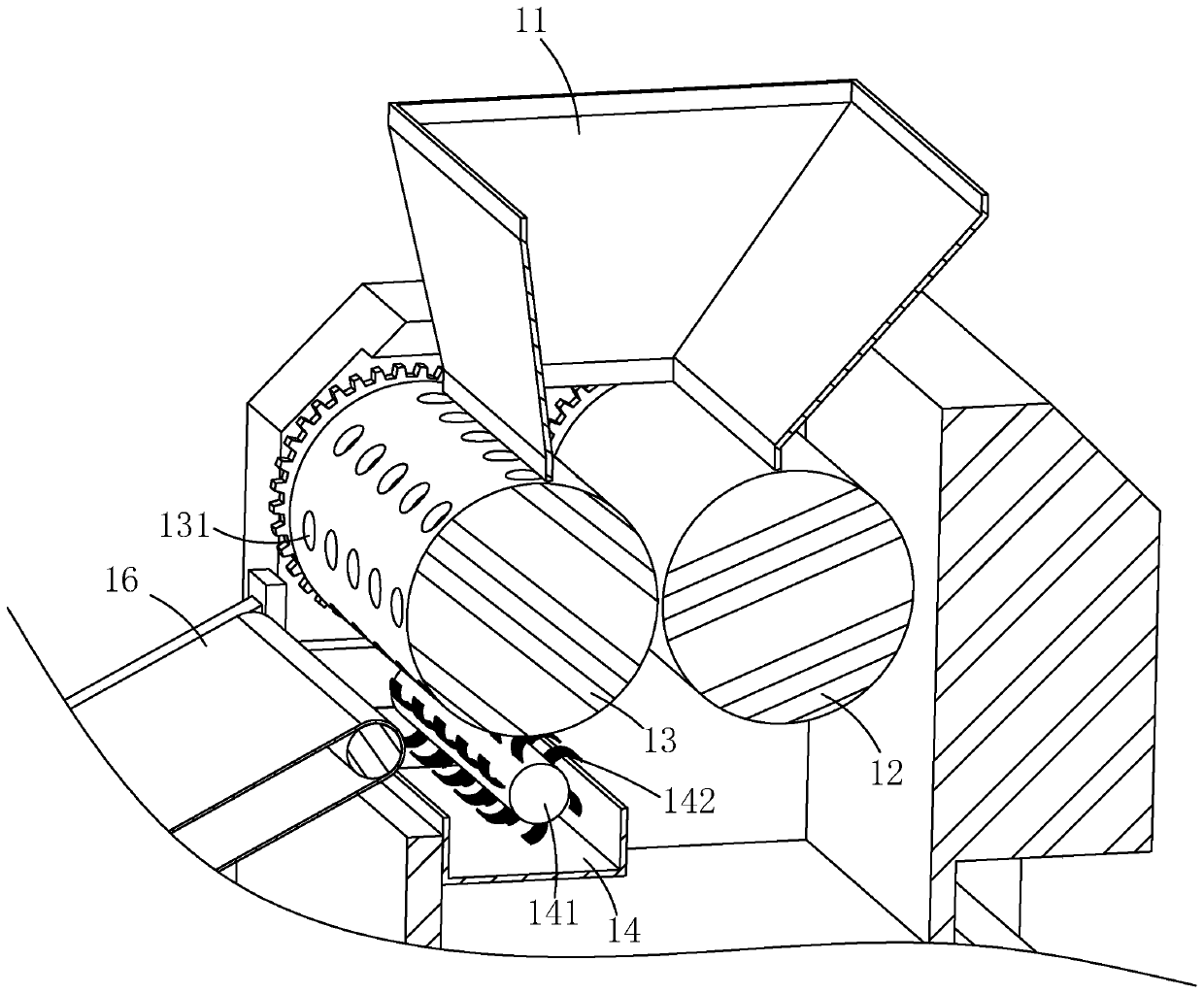

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] refer to figure 1 , is a peach cake roll printing machine disclosed by the present invention, comprising a frame 1, a feed hopper 11, a feeding roller 12, a mold roller 13 and a canvas conveyor belt 16, wherein the feeding roller 12 is rotatably connected to the frame 1 And be positioned at the directly below of feeding hopper 11, and feed roller 12 is coated with non-stick layer outside, in the present embodiment non-stick layer has polytetrafluoroethylene coating and forms, and mold roll 13 is rotatably connected on frame 1 The top is horizontally adjacent to the feeding roller 12, and the rotation direction of the mold roller 13 is opposite to that of the feeding roller 12, and the outer peripheral walls of the feeding roller 12 and the mold roller 13 abut against each other, and the outer peripheral wall of the mold roller 13 A plurality of mold g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com