Tubular condensation water and mist removal method and device

A condensation dehydration, tube-type technology, applied in separation methods, chemical instruments and methods, steam condensation, etc., to reduce environmental pollution, improve recycling rate, and improve removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0030] It is used for repurification of wet desulfurization tail gas of 470t / h boiler flue gas, and the treated flue gas volume is 600,000m 3 / h, SO in flue gas imported from desulfurization 2 The content is 3000mg / Nm 3 , dust content 13mg / Nm 3 . Flue gas volume after wet desulfurization is 630000m 3 / h, the temperature is 51°C, the relative humidity is 95%, the absolute humidity is 12.8% water vapor content, and the sulfur dioxide content is 33mg / Nm 3 , dust content 11mg / Nm 3 , droplet content 5000mg / Nm 3 . The clean flue gas after wet desulfurization is dehydrated and demisted by the present invention.

[0031] Method and structure:

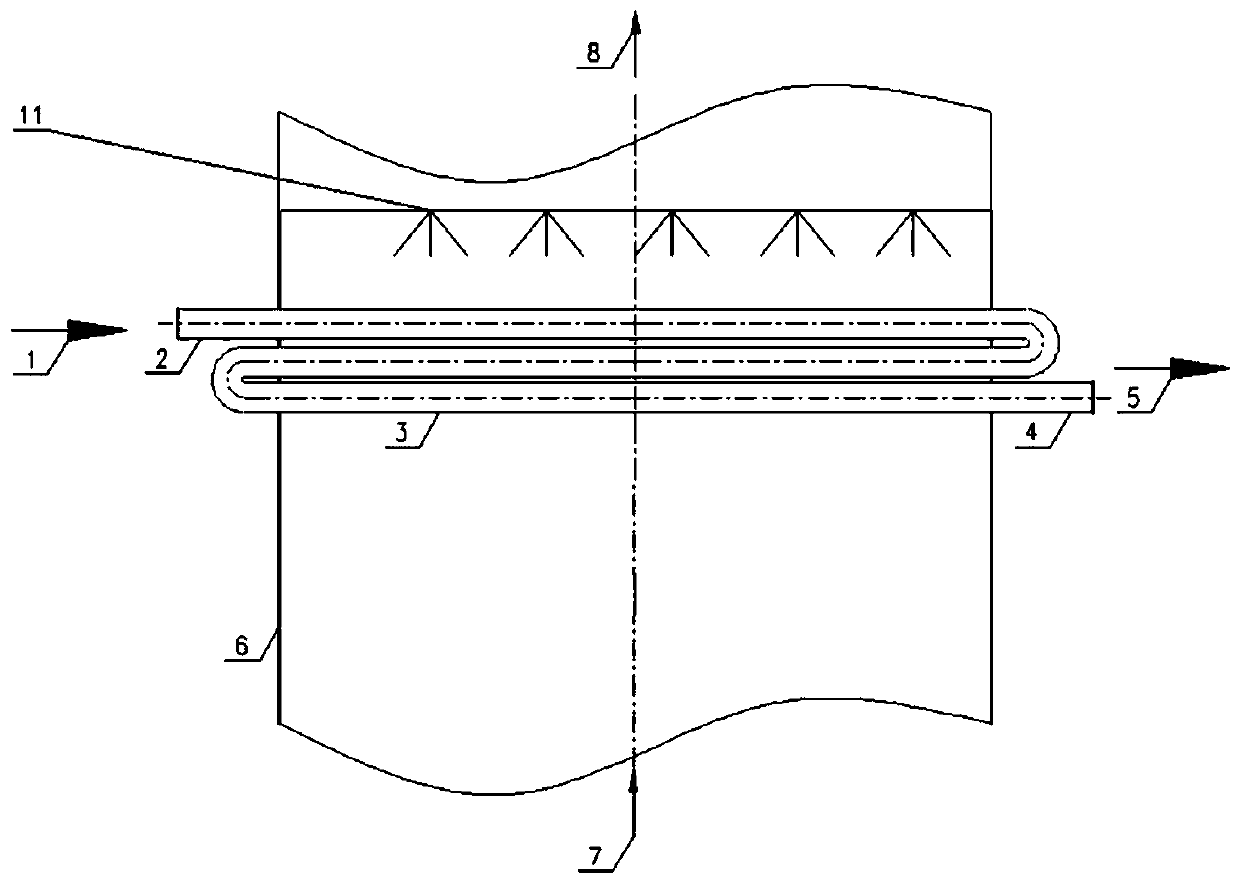

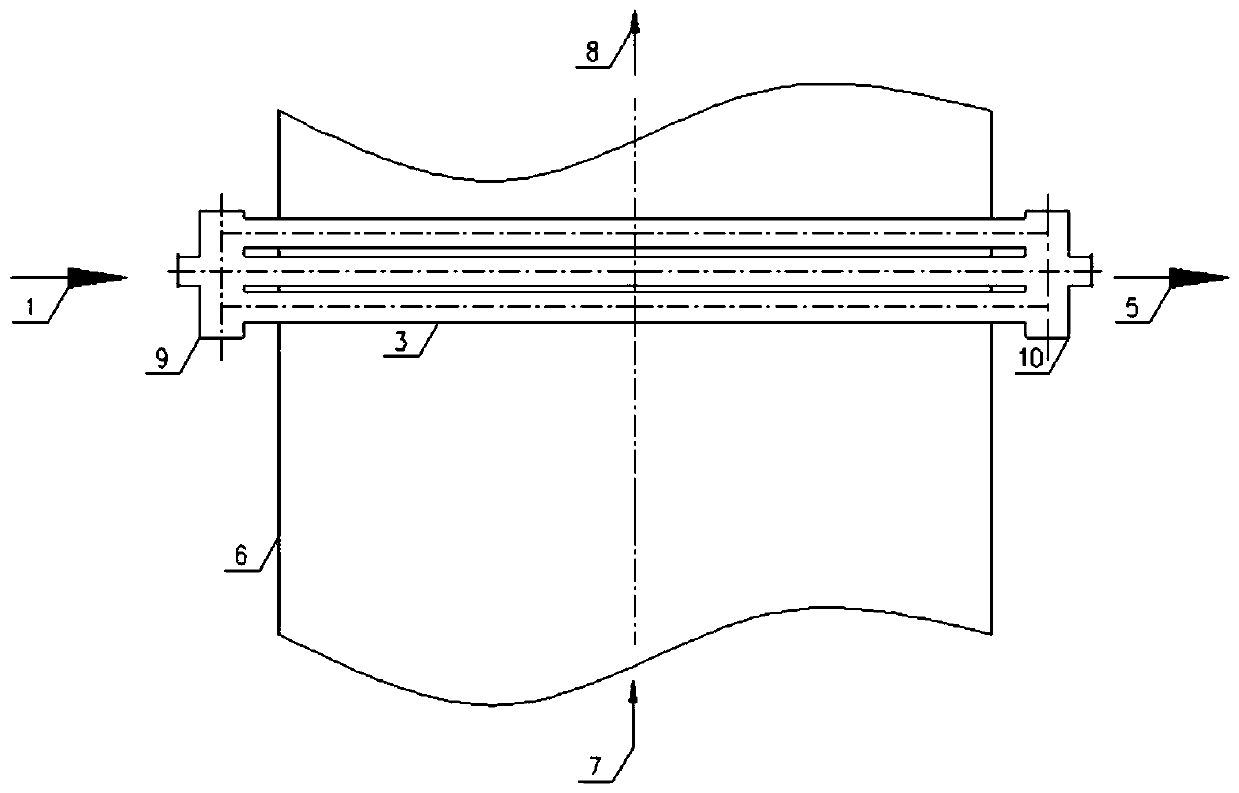

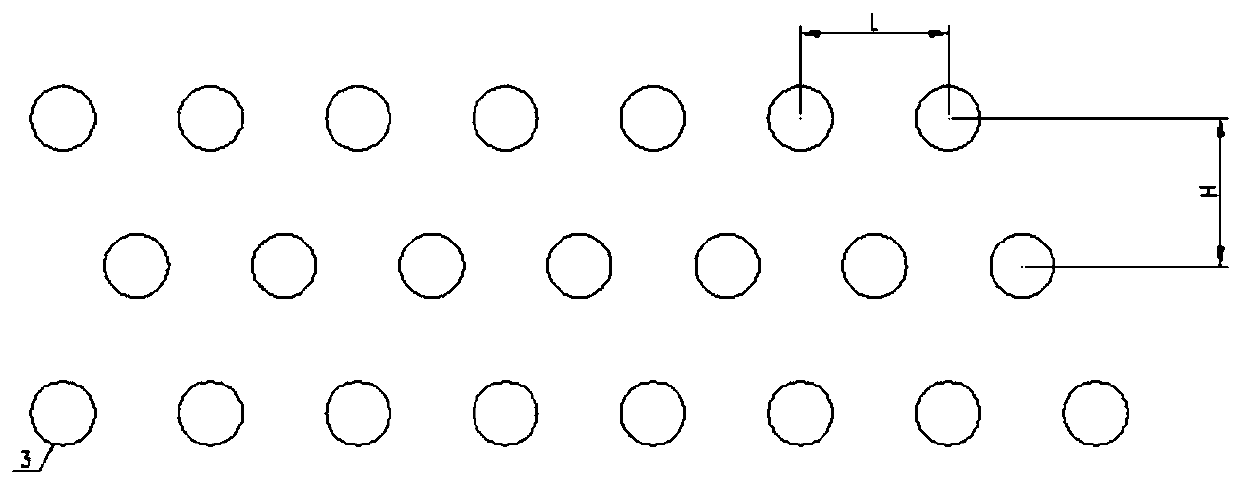

[0032] The tube-type condensing dehydration demister for desulfurization tail gas dehydration and mist removal is attached figure 1 , image 3 , Figure 4 .

[0033] The tubular condensation dehydration demister is located after the desulfurization purification equipment spray absorption, the gas enters the tubular condensation deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com