Method and device for testing slurry droplets of wet desulphurization system

A wet desulfurization and slurry technology, applied in measuring devices, sampling devices, weighing by removing certain components, etc., can solve the problems of difficult to clean droplet scale, incomplete recovery of magnesium ions, difficult practical operation, etc. The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

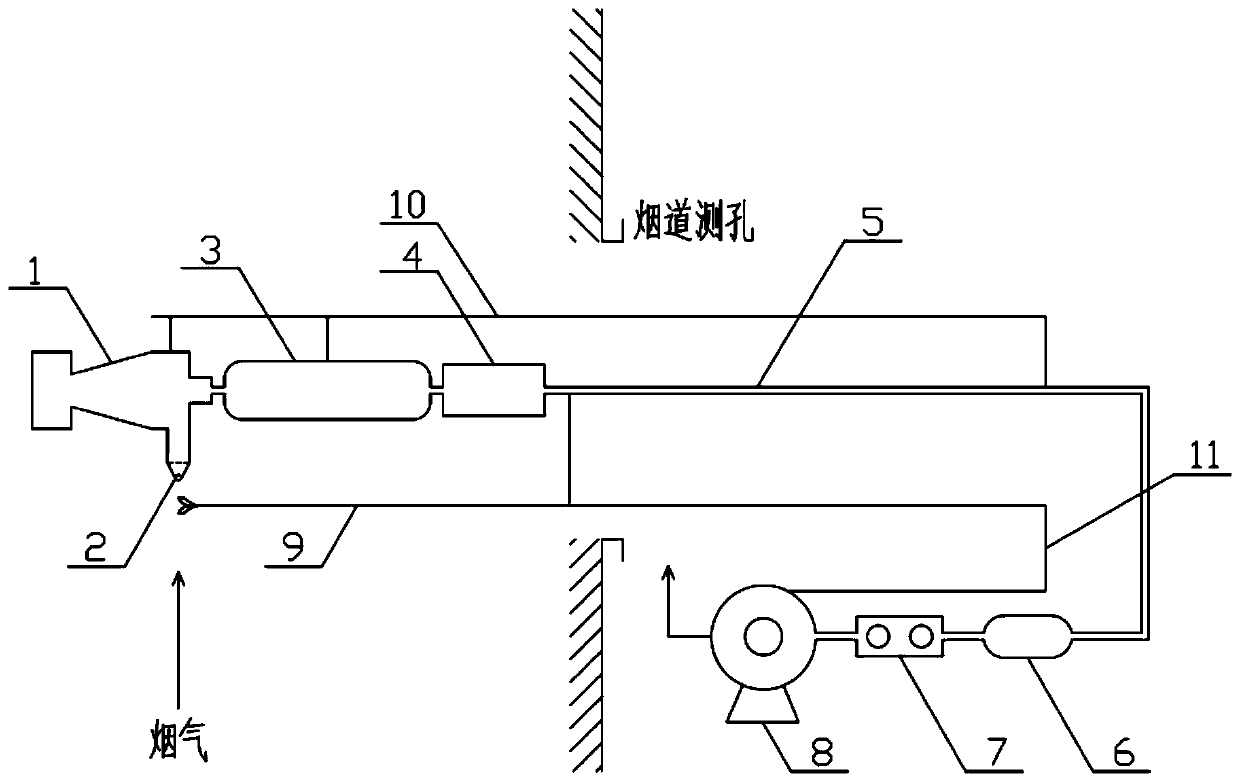

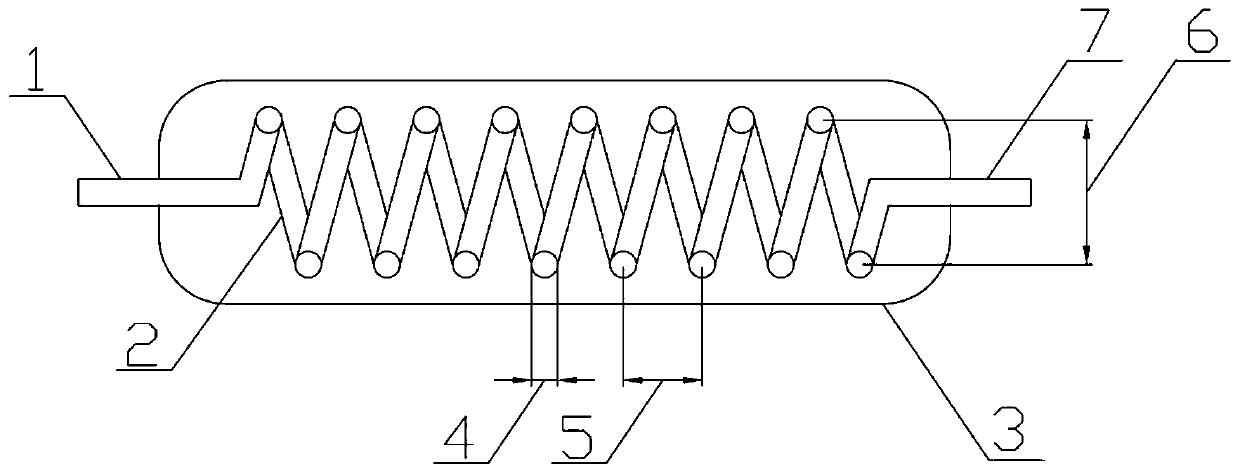

[0058] Such as figure 1 As shown, the slurry mist sampling device of the wet desulfurization system of the present invention comprises in turn: a fog collecting device, a dehumidification device 6, a metering device 7 and a power device 8, and the fog collecting device consists of a cyclone catcher 1, a serpentine tube 3 and The anti-backflow device 4 is formed by connecting, and the mist collecting device is connected with the dehumidification device 6 through the sampling pipe or sampling gun 5 . A sampling nozzle 2 is installed on the intake pipe of the cyclone collector 1; the cyclone collector 1, the serpentine pipe 3, and the anti-backflow device 4 are fixedly connected with the sampling pipe or the sampling gun 5 through the support structure;

[0059] The device also includes an S-shaped pitot tube 9, which is connected to the power unit 8 through a dynamic and static pressure balance communication pipe 11, and the air inlet of the pitot tube is on the same longitudina...

Embodiment 2

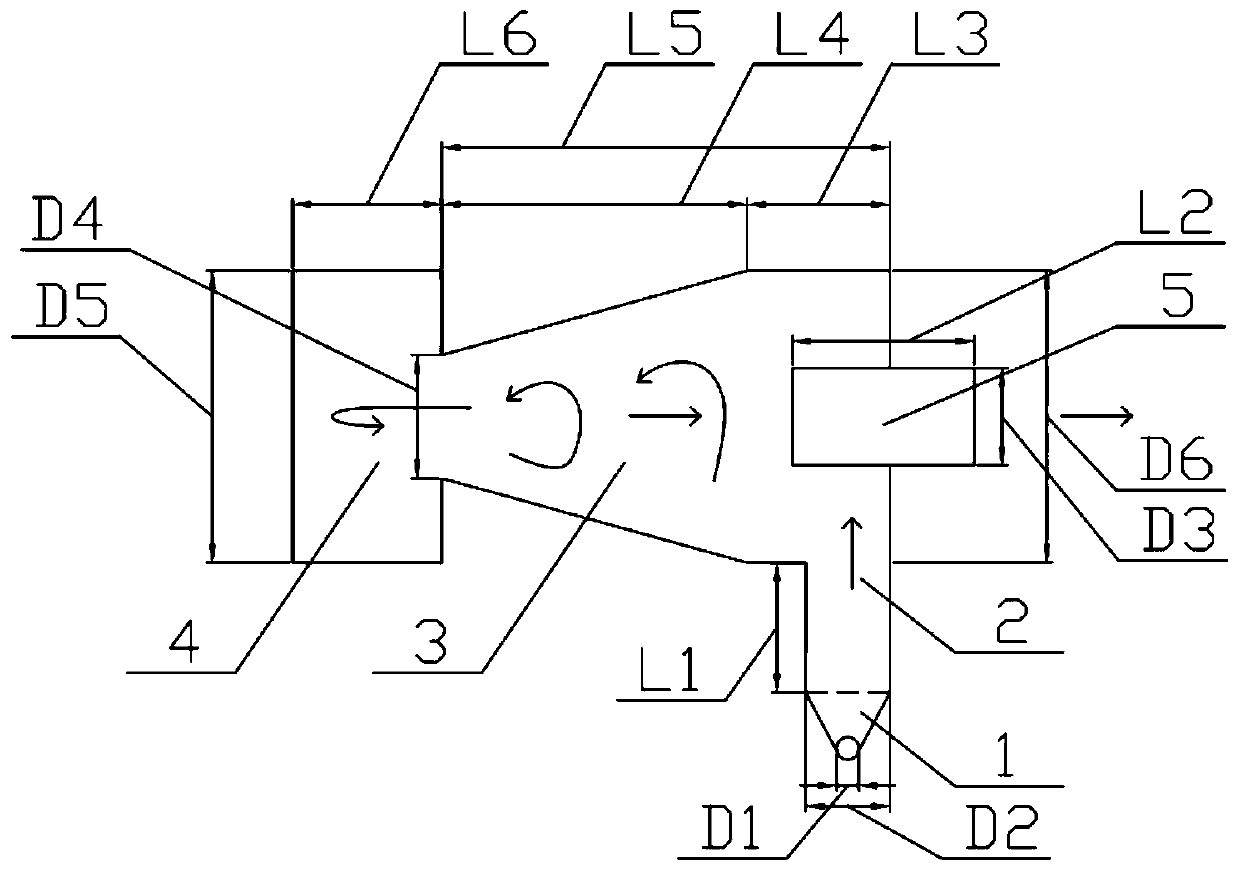

[0062] The optional design of this example is that the structure of the cyclone catcher is as follows figure 2 As shown, the cyclone catcher includes a cone 3, the bottom end of the cone 3 is provided with an air intake pipe 2 for collecting flue gas, the front end of the cone 3 is provided with a mist collection chamber 4 for cutting slurry droplets, and the rear end of the cone 3 is provided with Exit pipe 5 is arranged, links to each other with serpentine pipe. A sampling nozzle 1 is also installed on the intake pipe 2 .

[0063] The extracted flue gas enters the cyclone collector tangentially through the sampling nozzle 1 and the air inlet pipe 2, and the droplets with an aerodynamic diameter of 10 μm or more will be collected in the cone due to centrifugal force and flow into the mist collection chamber; the aerodynamic diameter Droplets below 10 μm follow the airflow, change the direction of the airflow at the entrance of the mist collection chamber, and flow out throu...

Embodiment 3

[0065] The optional design of this example lies in, such as figure 1 , The cyclone collector 1, the serpentine pipe 3, and the backflow prevention device 4 are connected through a Teflon connecting pipe; the dehumidification device 6 is filled with hygroscopic silica gel. The metering device 7 is provided with a temperature probe and a pressure probe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com