Wood facing and wood facing manufacturing method

A production method and wood veneer technology, applied in the field of wood veneer or wood, can solve problems such as poor wood texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

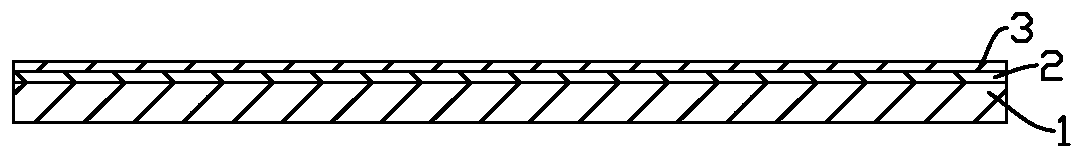

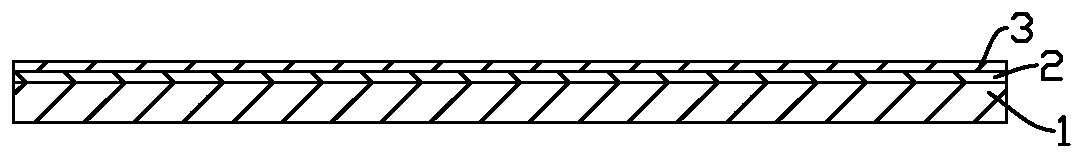

Image

Examples

Embodiment 1

[0040] This embodiment discloses a method for making a wood veneer, which includes the following steps in sequence:

[0041] veneer or wood pretreatment step, veneer or wood is bleached;

[0042] Dipping or coating step, dipping the veneer or wood pre-treated veneer or wood into the slurry to carry out the dipping treatment or using a coating process to apply the slurry to the surface of the veneer or wood; wherein, the slurry It consists of the following components in mass percentage: 0.1% of cationic polysaccharide, 1% of cationic polyurethane, and the balance is water. In this embodiment, the cationic polysaccharide is selected from cationic etherified starch, cationic starch or cationic guar gum. Of course, the cationic polysaccharide can also be selected from other cationic polysaccharides.

[0043] drying step, drying the product obtained in the dipping or coating step;

[0044] Digital printing step, using digital printing equipment to spray ink onto the product obta...

Embodiment 2

[0047] This embodiment discloses a method for making a wood veneer, which includes the following steps in sequence:

[0048] veneer or wood pretreatment step, veneer or wood is bleached;

[0049] Dipping or coating step, dipping the veneer or wood pre-treated veneer or wood into the slurry to carry out the dipping treatment or using a coating process to apply the slurry to the surface of the veneer or wood; wherein, the slurry It consists of the following components in mass percentage: 10% of cationic polysaccharide, 20% of cationic polyurethane, and the balance is water. In this embodiment, the cationic polysaccharide is selected from cationic etherified starch, cationic starch or cationic guar gum. Of course, the cationic polysaccharide can also be selected from other cationic polysaccharides.

[0050] drying step, drying the product obtained in the dipping or coating step;

[0051] Digital printing step, using digital printing equipment to spray ink onto the product obta...

Embodiment 3

[0054] This embodiment discloses a method for making a wood veneer, which includes the following steps in sequence:

[0055] veneer or wood pretreatment step, veneer or wood is bleached;

[0056] Dipping or coating step, dipping the veneer or wood pre-treated veneer or wood into the slurry to carry out the dipping treatment or using a coating process to apply the slurry to the surface of the veneer or wood; wherein, the slurry It consists of the following components in mass percentage: 5% cationic polysaccharide, 10% cationic polyurethane, and the balance is water. In this embodiment, the cationic polysaccharide is selected from cationic etherified starch, cationic starch or cationic guar gum. Of course, the cationic polysaccharide can also be selected from other cationic polysaccharides.

[0057] drying step, drying the product obtained in the dipping or coating step;

[0058] Digital printing step, using digital printing equipment to spray ink onto the product obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com