Material distribution system based on stereoscopic warehouse

A batching system and vertical warehouse technology, applied in electromagnetic radiation induction, transportation and packaging, storage devices, etc., can solve the problems of hard to seal the storage area of the material box, high labor intensity, time delay and batching efficiency, etc., to achieve The effect of improving the level of factory information interaction, improving the level of workshop automation, and saving the time for picking and placing material boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

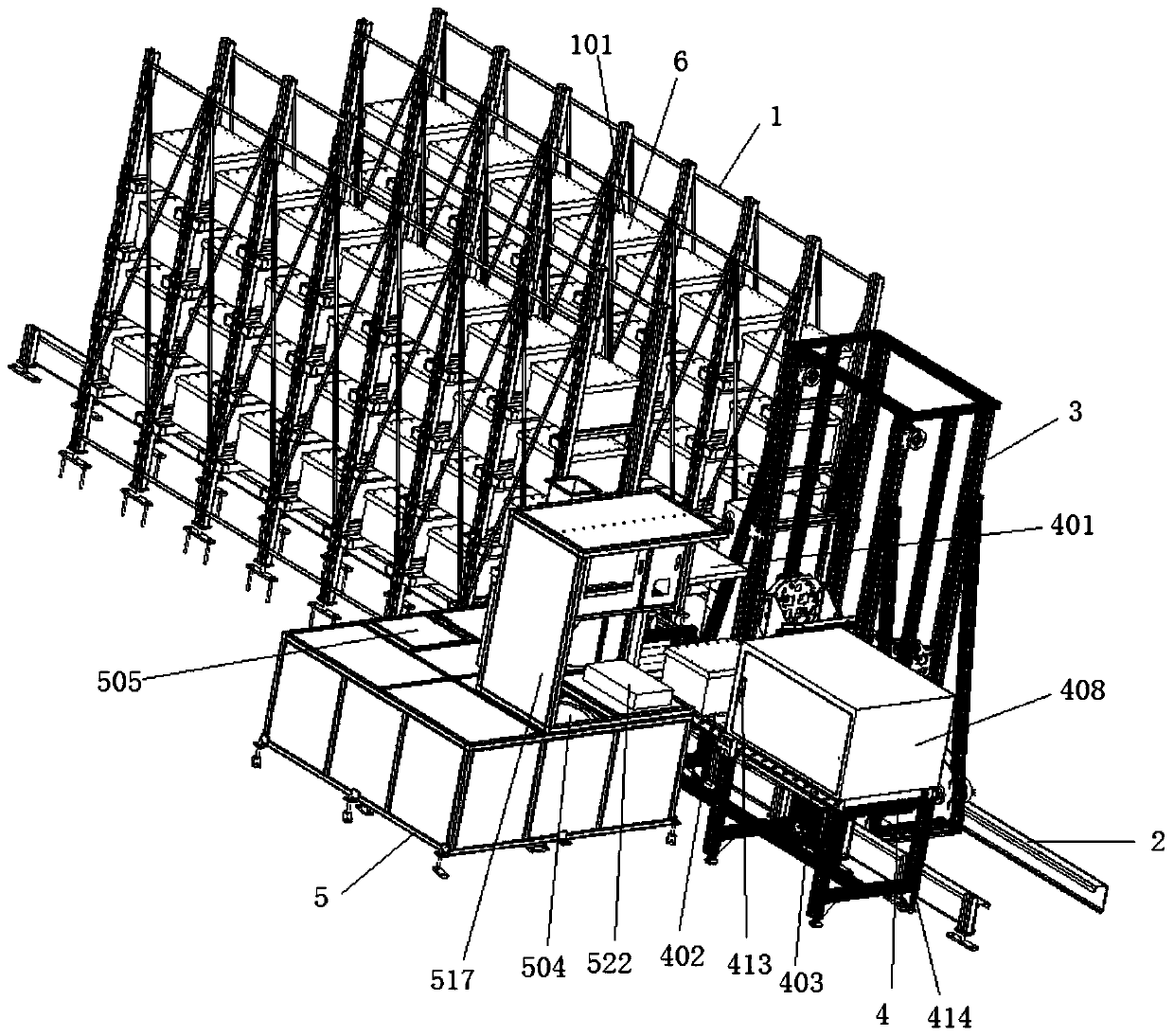

[0035] Such as figure 1 As shown, a batching system based on a vertical warehouse includes a vertical warehouse 1, a track 2, a stacker 3, a conveying mechanism 4, and a batching mechanism 5.

[0036] A plurality of storage positions 101 are set on the vertical warehouse 1 for storing a plurality of material boxes 6 , and the storage positions 101 place the material boxes 6 . A bar code is pasted on the material box 6 for verifying the information of the material box.

[0037] The track 2 runs through the vertical warehouse 1 and is set.

[0038] The stacker 3 bidirectionally moves on the track 2, the stacker 3 picks and releases the material box 6 on the vertical warehouse 1, and the stacker 3 picks and releases the material box 6 on the conveying mechanism 4.

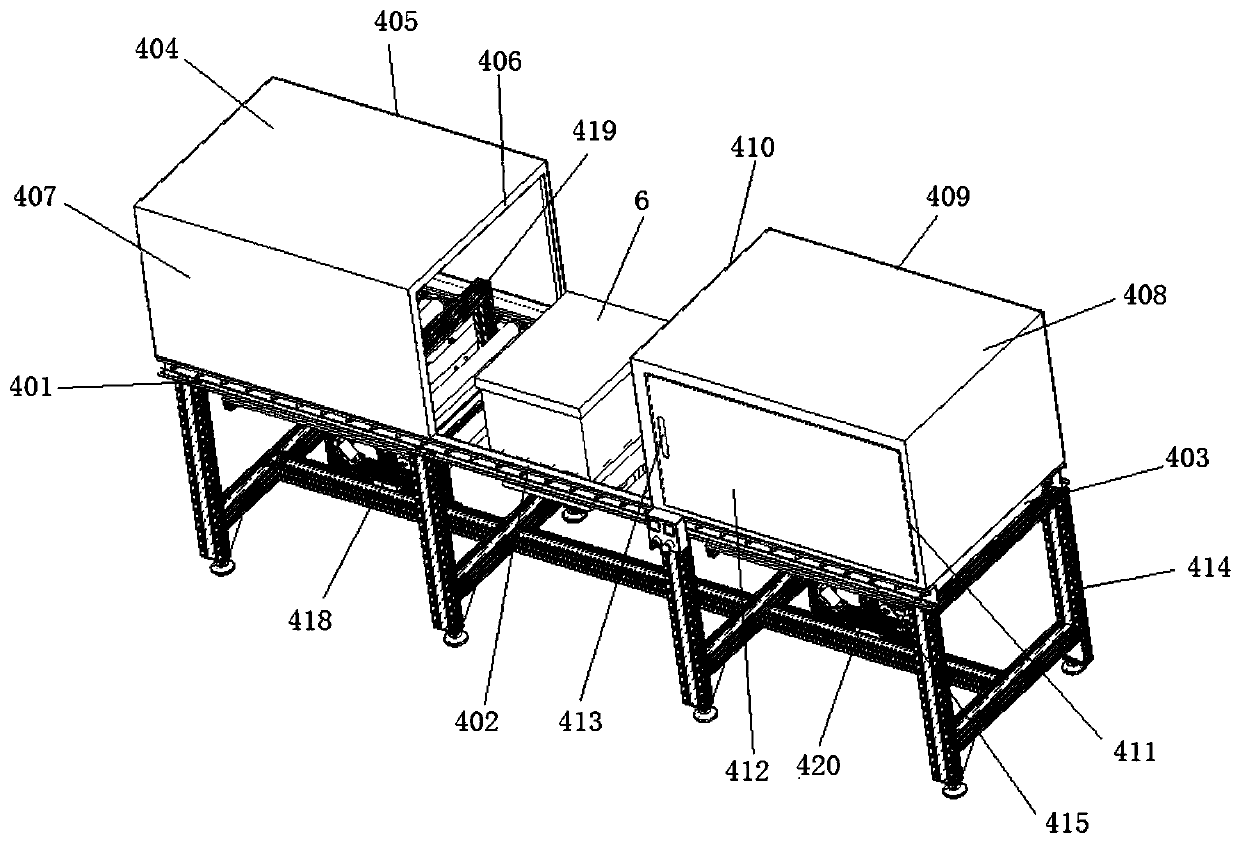

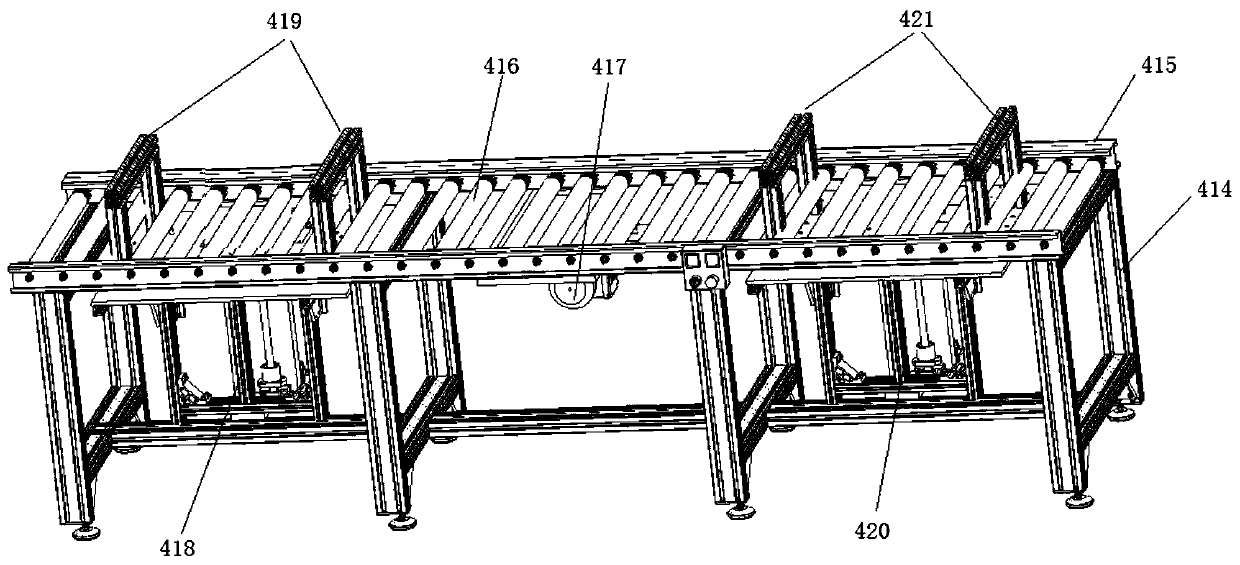

[0039] The conveying mechanism 4 includes a conveying assembly and a verification assembly arranged on the conveying assembly. The conveying assembly is used to convey the material box to the batching position, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com