Method and device for vertical lifting of muck

A muck and vertical technology, applied in the field of muck vertical lifting methods and devices, can solve the problems of discontinuous excavation, inability to realize muck crushing and filtering classification, and inability to effectively control the impact force of muck, etc. , to achieve the effect of low transportation cost, guaranteed excavation speed and continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

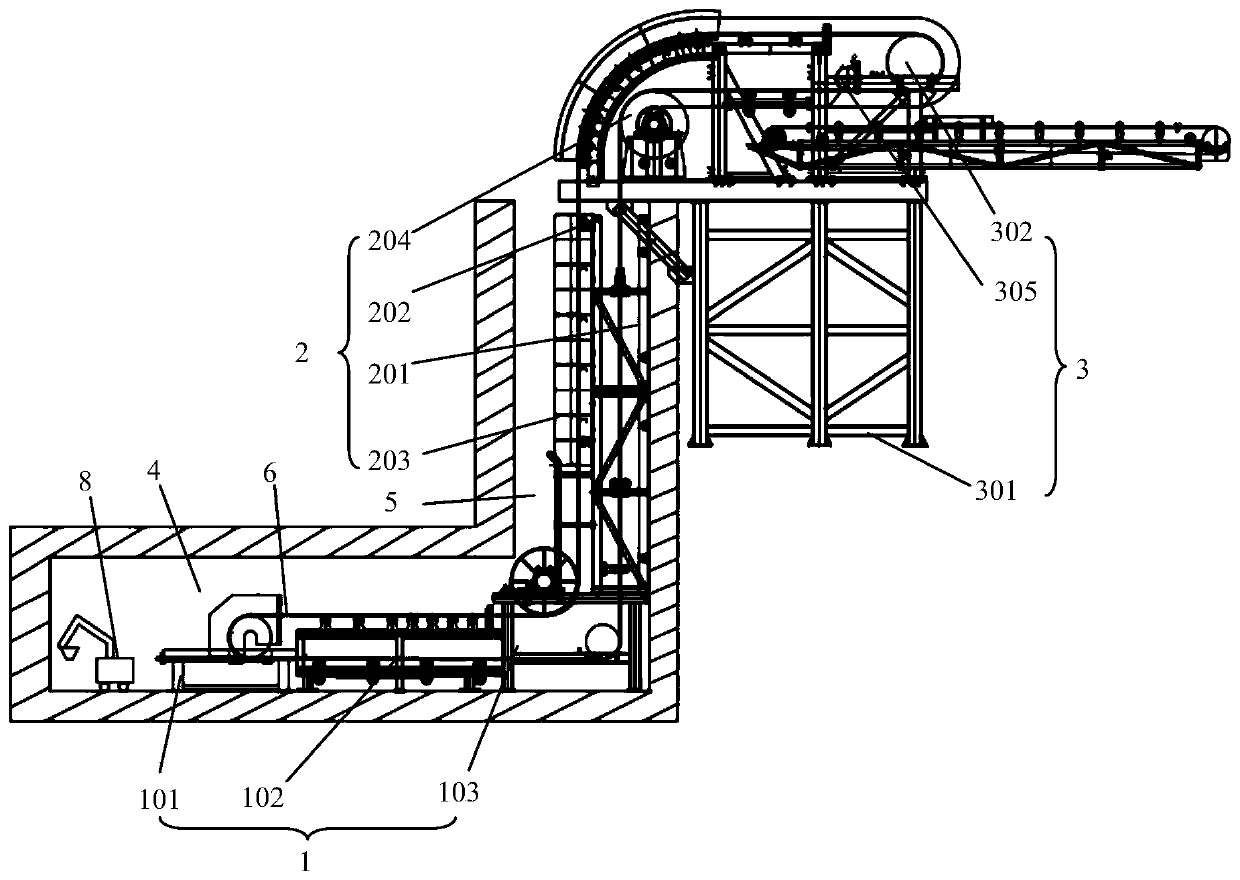

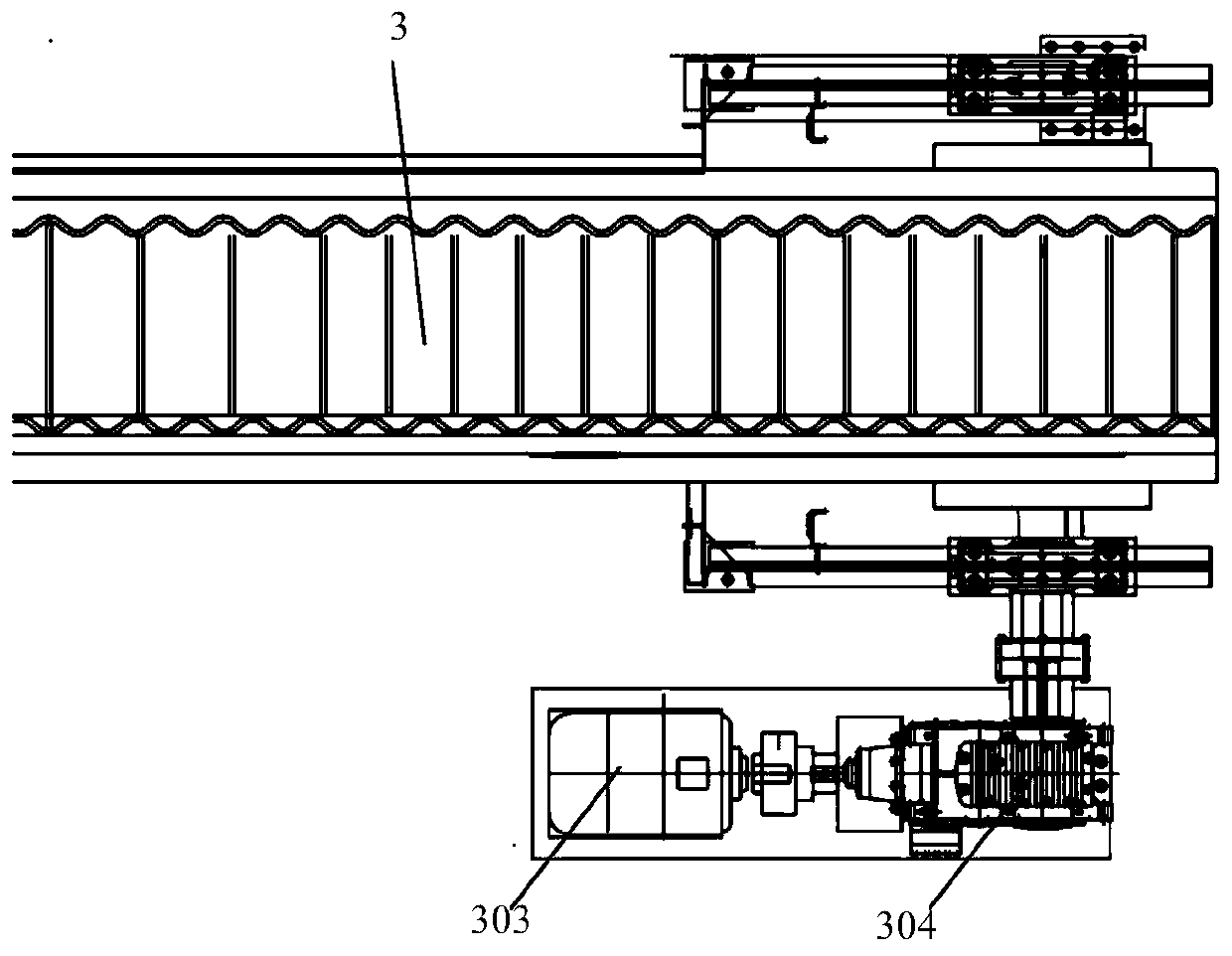

[0053] Such as figure 1 As shown, the present invention provides a muck vertical lifting device, which can be used in the construction of subway underground tunnels or deep foundation pits. The muck vertical lifting device at least includes a first horizontal conveying part 1 , a vertical lifting part 2 and a second horizontal conveying part 3 . The first horizontal conveying part 1 is arranged at the bottom of the tunnel 4 to transfer, for example, muck excavated by an excavator to the bottom of the shaft. The vertical lifting part 2 is arranged on the side wall of the shaft 5, and is used for vertically lifting the muck at the bottom of the shaft, and then can lift the muck to the surface along the shaft 5. The second horizontal conveying part 3 is arranged on the ground surface, and it is used for transferring the dregs lifted by the vertical lifting part 2 to the muck storage yard, for example. The vertical lifting part 2 can transport the muck from the first horizontal ...

Embodiment 2

[0059] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

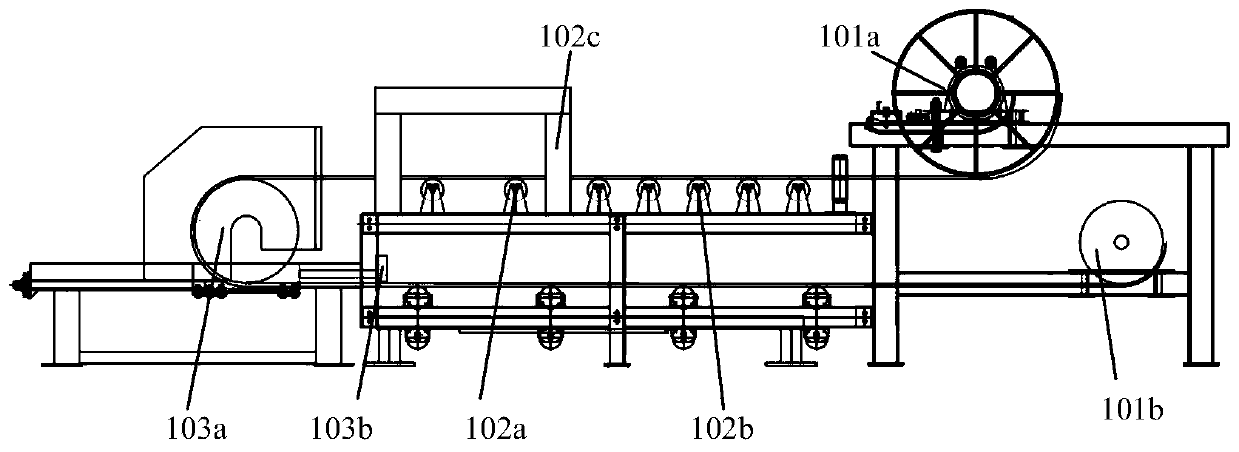

[0060] preferred, such as figure 2 As shown, the second support 102 is also provided with several parallel rollers 102b and material guide grooves 102c. The first horizontal conveying part plays the role of conveying materials through the joint rotation of the parallel idler roller 102b and the buffer idler roller 102a. Both the parallel idler roller and the buffer idler roller are arranged on the second support 102 in a manner parallel to each other. The material guide trough 102c and the buffer roller 102a are used as a pair. That is, the material guide groove 102c is arranged above the buffer idler roller 102a. The material guide trough 102c is used to receive, for example, muck excavated by an excavator, and then pour the muck onto the belt 6 on the buffer idler roller 102a. The first muck and / or the second muck can be transported through the buffer idler...

Embodiment 3

[0067] This embodiment is a further improvement on the foregoing embodiments, and repeated content will not be repeated here.

[0068] preferred, such as Figure 6 As shown, the first horizontal conveying part 1 is arranged at the intersection of the tunnel 4 and the shaft 5 . The muck vertical lifting device further includes an extended conveying part 7 composed of a first conveying unit 701 , a buffer unit 702 and a second conveying unit 703 . The extension conveying part 7 is arranged in the tunnel 4, and as the excavation continues, the length of the tunnel 4 will continue to increase. Continuous transfer.

[0069] Preferably, the first conveying unit 701 and the second conveying unit 703 may be belt conveyors. Along the extending direction of the tunnel 4, a first conveying unit 701, a buffer unit 702 and a third conveying unit 703 are sequentially arranged from inside to outside. The first conveying unit 701 is close to the excavation face of the tunnel 4 , so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com