Underactuation crane operating whole process active-disturbance-rejection control method of single parameter adjustment

A technology of active disturbance rejection control and active disturbance rejection controller, which is applied in the directions of load suspension components, transportation and packaging, etc., can solve the problems of difficult popularization and application, increased cost of installing speed sensors, and difficulty in load swing angular velocity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

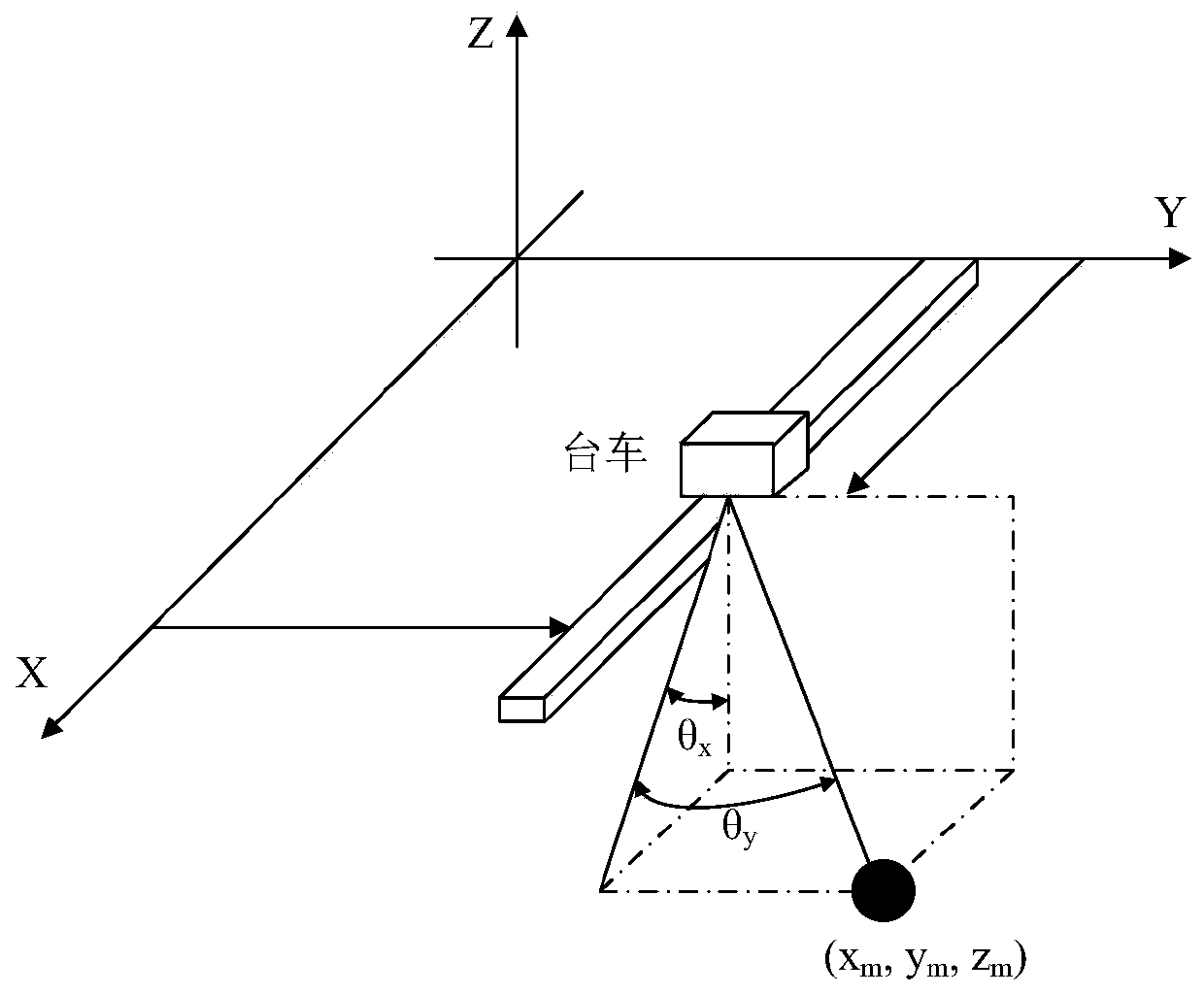

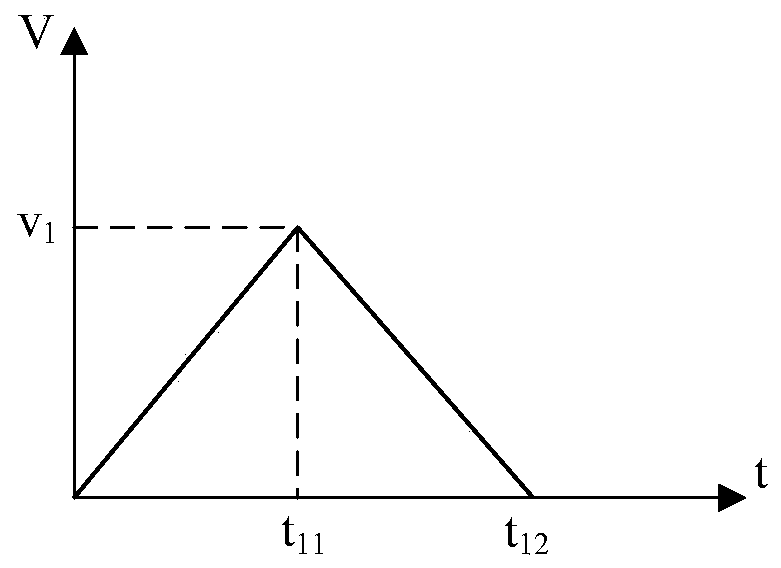

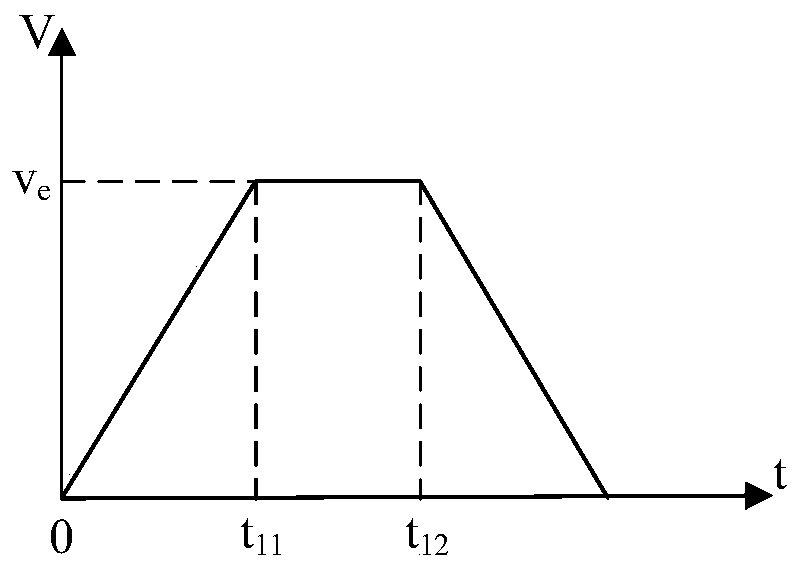

[0060] The basic idea of the active disturbance rejection control method for the whole process of underactuated crane operation of the present invention is: firstly, according to the motion characteristics of the underactuated crane, establish the state equation of the underactuated crane, and then, according to the starting and target positions of the trolley, consider the According to the safety constraints such as speed, acceleration and operating environment, the ideal operating trajectory of the trolley with priority on efficiency is generated, and compared with the actual position of the trolley, an error feedback control law for the movement of the trolley is constructed. Considering that uncertain factors such as rope length, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com