Water reducing agent and preparation method thereof

A technology of water reducing agent and initiator, which is applied in the field of water reducing agent and its preparation, which can solve the problems of compatibility difficult to meet the requirements of admixtures, long concrete setting time, and large amount of early strength agent, so as to avoid steam Maintenance costs, outstanding economic benefits, and the effect of improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the invention also discloses a preparation method of the water reducing agent, which includes the following steps:

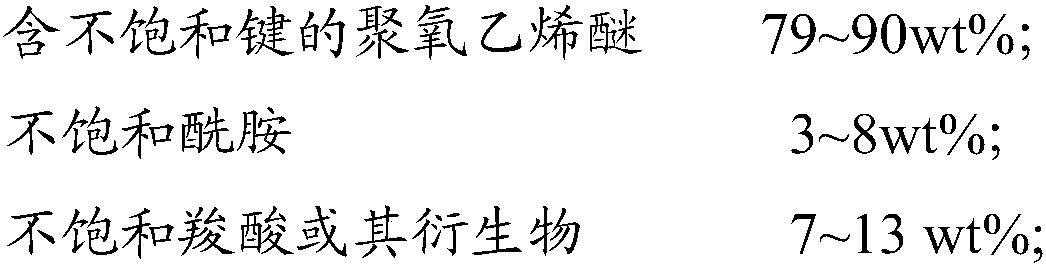

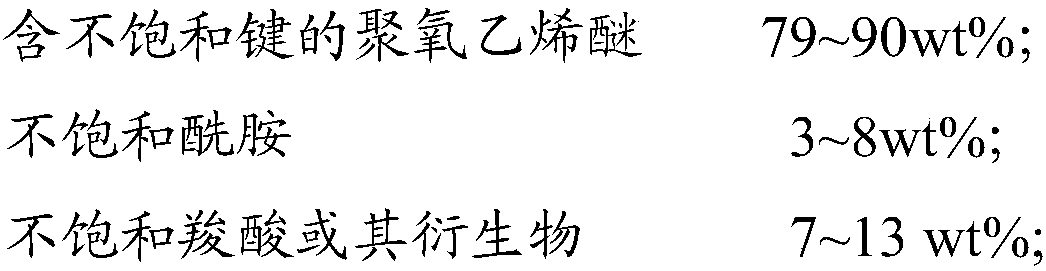

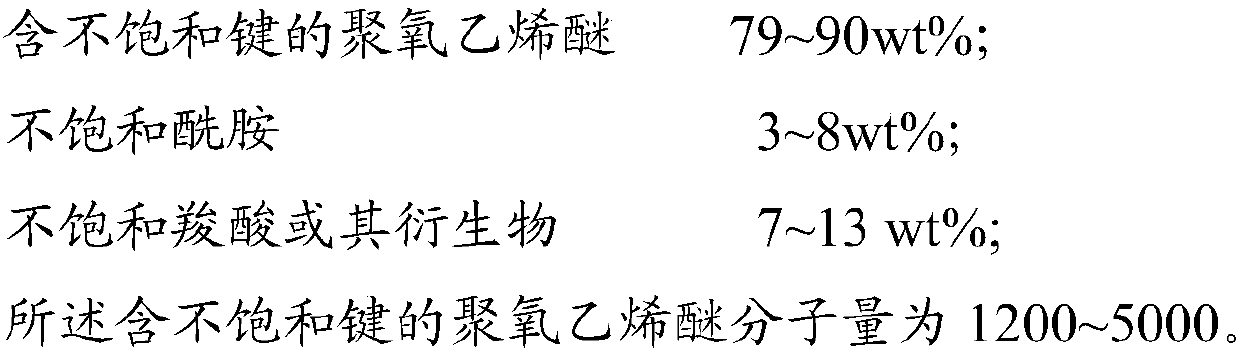

[0033] Mixing unsaturated bond-containing polyoxyethylene ether, unsaturated amide, initiator and water to obtain a mixed solution; the addition amount of the initiator is 0.1 to 5% of the total mass of the unsaturated monomer;

[0034] Dissolve the unsaturated carboxylic acid monomer or its derivative in water to obtain a combined solution A;

[0035] Mix the reducing agent, the chain transfer agent and water to obtain the combined solution B; the addition amount of the reducing agent is 0.1 to 6% of the total mass of the unsaturated monomer; the addition amount of the chain transfer agent is the total mass of the unsaturated monomer 0.1~6%;

[0036] The combination liquid A and the combination liquid B are added dropwise to the mixed liquid to carry out a polymerization reaction to obtain a water reducing agent;

[0037] The unsaturated monomer...

Embodiment 1

[0050] In a four-necked flask equipped with a thermometer, a stirrer and a constant-flow dripping pump, add 312.0g of water, 355g of prenol-based polyoxyethylene ether (molecular weight 1200) and start stirring, then add 20g of acrylamide and mix Evenly, the temperature is raised to 60° C., and 6.2 g of 30% hydrogen peroxide is added to obtain a mixed solution.

[0051] 28.6g acrylic acid was dissolved in 180.0g deionized water to obtain a combination liquid A;

[0052] 0.7g of ascorbic acid and 3.1g of mercaptopropionic acid were dissolved in 100.0g of deionized water and mixed uniformly to obtain a combination liquid B;

[0053] In the mixed liquid, start to drip the combined liquid A and the combined liquid B respectively, and the uniform dripping is completed within 2.5 hours. The temperature of the reaction system is maintained at 58℃~62℃, after that, the temperature of the system is increased to 68~72℃, and the constant temperature stirring is continued for 1.5h. Finally, the ...

Embodiment 2

[0055] In a four-necked flask equipped with a thermometer, a stirrer, and a constant-flow dripping pump, add 320g of water, 355.8g of prenol-based polyoxyethylene ether with a molecular weight of 2400 and start stirring, then add 25g of acrylamide and mix well. The temperature was raised to 60° C., and 6.2 g of hydrogen peroxide with a mass concentration of 30% was added to obtain a mixed solution.

[0056] 30g acrylic acid is dissolved in 180g deionized water to obtain a combination liquid A;

[0057] 0.6 g of ascorbic acid and 2.3 g of mercaptopropionic acid were dissolved in 100 g of deionized water and mixed uniformly to obtain a combination liquid B;

[0058] In the mixed liquid, start to drip the combined liquid A and the combined liquid B respectively, and the uniform dripping is completed within 2.5 hours. The temperature of the reaction system is maintained at 58℃~62℃, after that, the temperature of the system is increased to 68~72℃, and the constant temperature stirring is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap