IF cold rolling steel with the tensile strength larger than or equal to 440 MPa and production method

A tensile strength, cold-rolled steel technology, applied in the field of IF cold-rolled steel and production, can solve the problems of poor plate shape, large fluctuation of hot-rolled incoming material strength, large fluctuation of mechanical properties, etc., to reduce thickness fluctuation, The effect of improved shape and stable strip rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below:

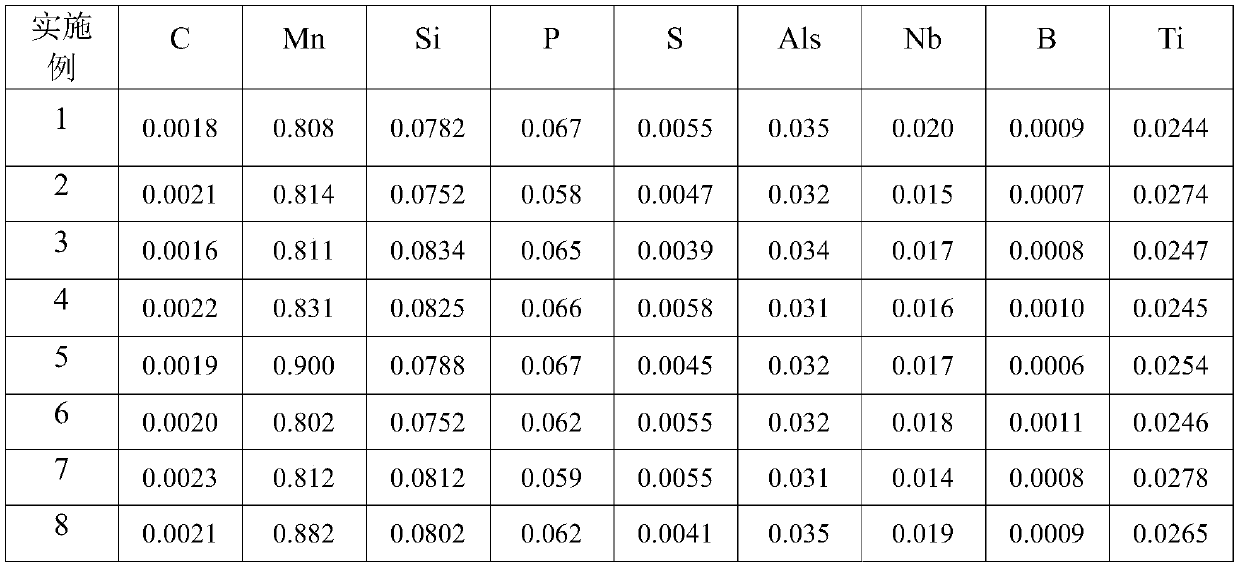

[0043] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

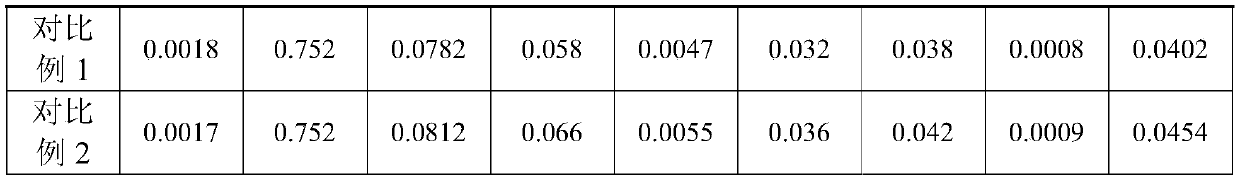

[0044] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

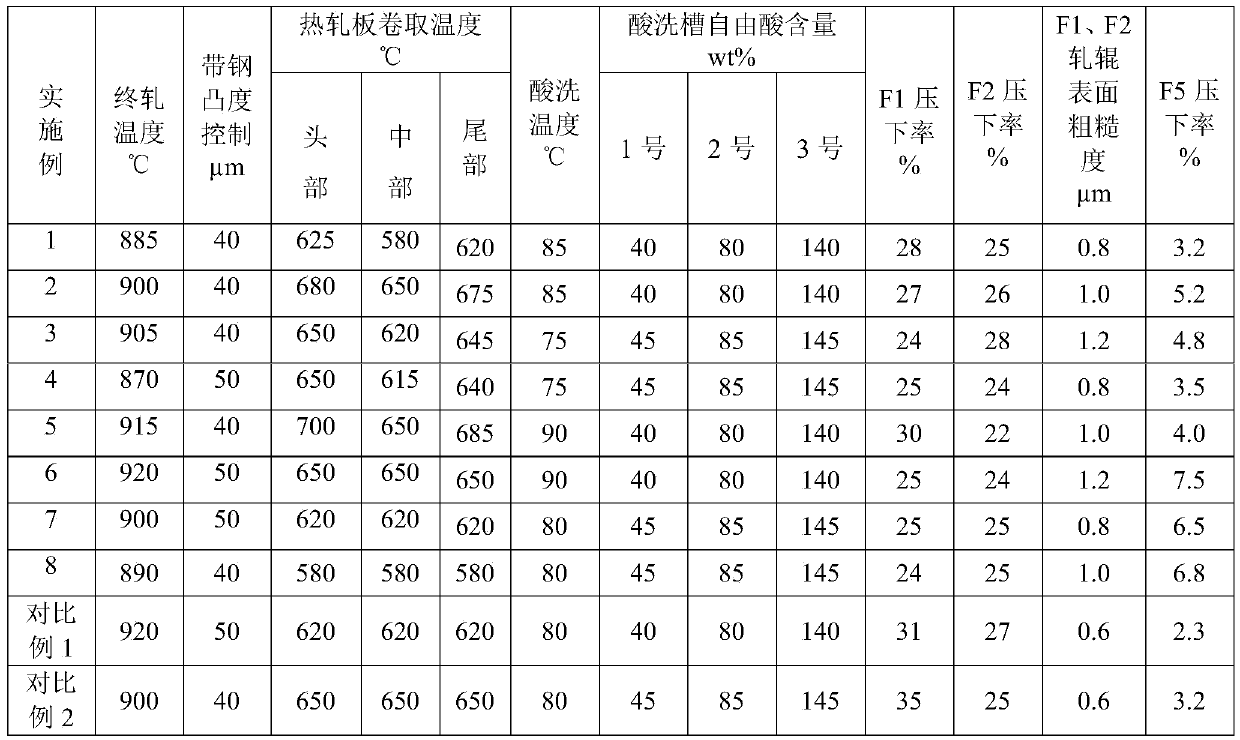

[0045] Table 3 is the performance list of each embodiment of the present invention and comparative examples.

[0046] Each embodiment of the present invention all produces according to the following steps:

[0047] 1) Conventionally smelted and cast into billets;

[0048] 2) Carry out rough rolling and finishing rolling, and control the finish rolling and final rolling temperature at 880-930°C; the surface roughness of the roll is controlled at no more than 40 μm;

[0049] 3) Cool the hot-rolled plate in sections to the coiling temperature: the coiling temperature of the head and tail of the steel strip with a length of no more than 150m is controlled at 620-700°C; the coiling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com