Silicon carbide single crystal growing device

A silicon carbide single crystal and growth device technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem of difficulty in achieving uniformity of graphite crucible temperature, waste of heating power, and affecting the growth of silicon carbide single crystal, etc. problems, to achieve the effect of improving the direction of heat transfer, improving the growth quality, and optimizing the heat conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

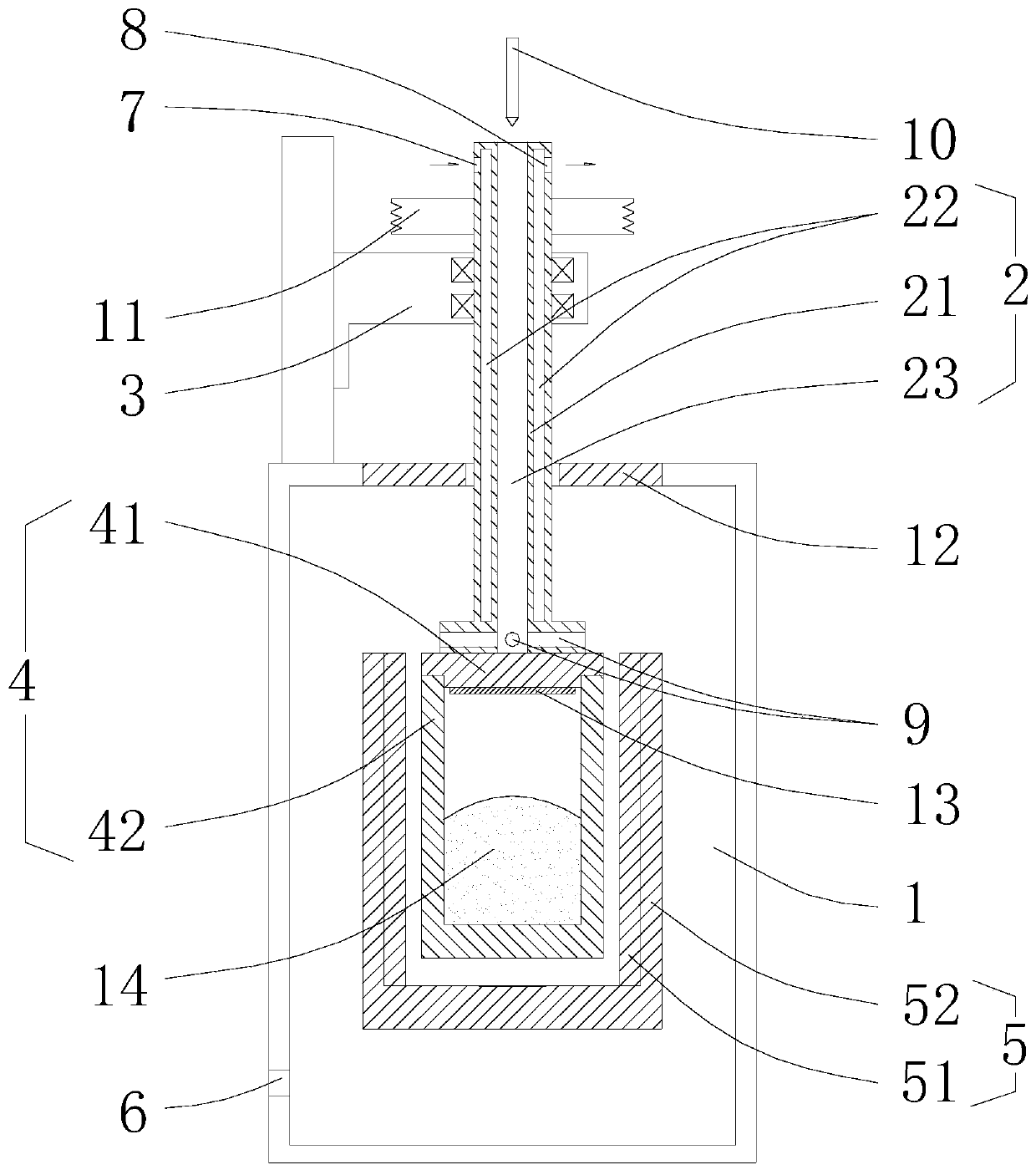

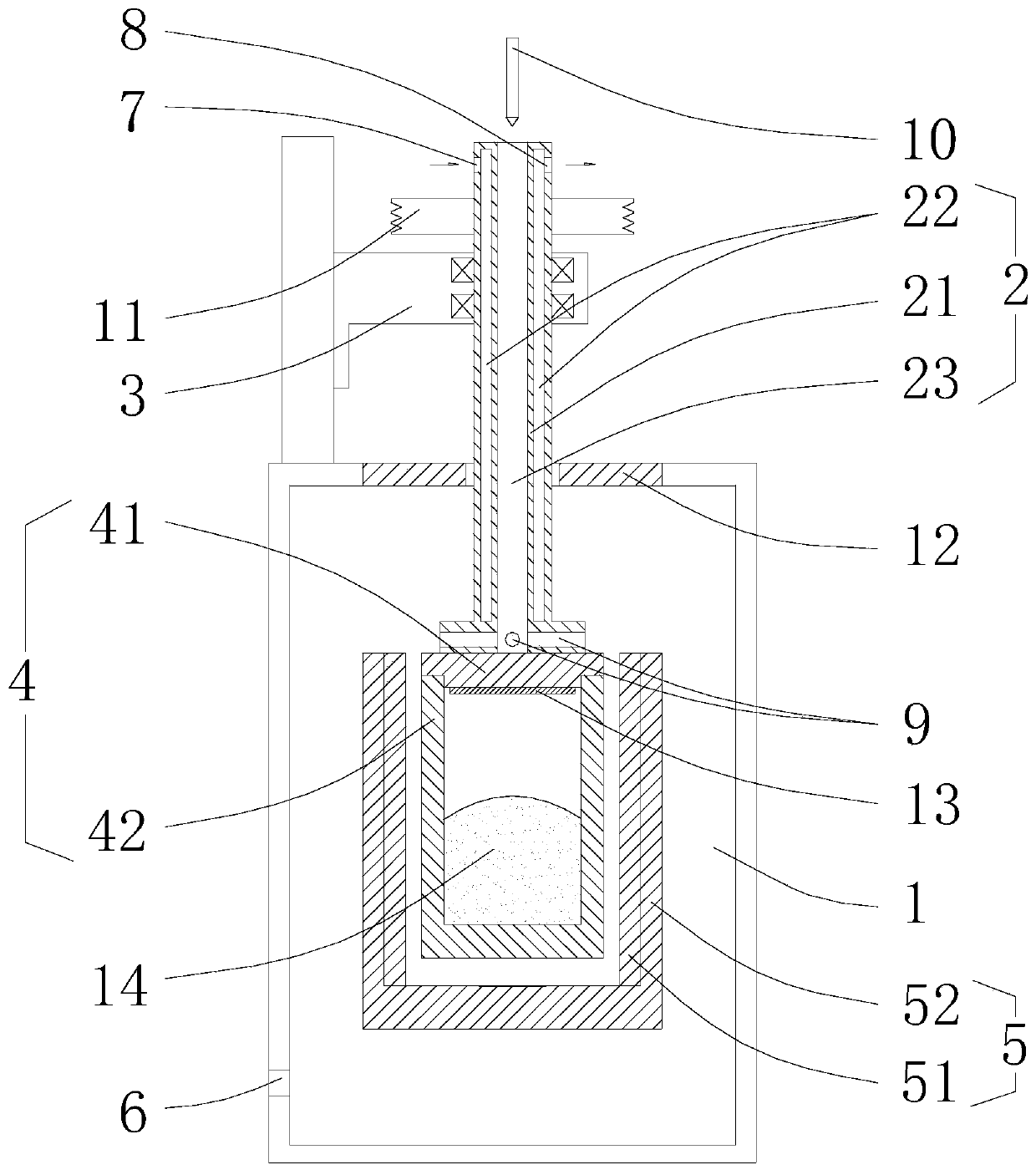

[0022] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] see figure 1 As shown, the above-mentioned silicon carbide single crystal growth device includes a working chamber 1, a connecting rod 2 that can be lifted and lowered through the working chamber 1, a first driving mechanism 3 for driving the connecting rod 2 to go up and down, a device A crucible 4 in the working chamber 1 and a heating mechanism 5 for heating the crucible 4 . The upper part of the working cavity 1 is provided with a cover plate 12. When it is necessary to load raw materials or take out finished products, the cover plate 12 is opened and the crucible 4 is lifted out of the working cavity 1. In this embodiment, the heating mechanism 5 includes a heating cylinder 51 surrounding the outer periphery of the crucible 4 , and a heat preservation cover 52 sleeved on the outer periphery of the heating cylinder 51 and opening u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com