Preparation method and application of rare earth ytterbium holmium double-doped pyrochlore phase nanofiber

A nanofiber, double-doping technology is applied in the direction of inorganic raw material rayon, etc., to meet the requirements of mass production, good repeatability, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing rare earth ytterbium holmium double-doped pyrochlore phase nanofibers of the present invention comprises the following steps:

[0034] S1, DMF and acetic acid are mixed and stirred according to the mass ratio of 1:(0.2~0.8), to obtain solution A;

[0035] S2. In the process of continuous stirring, tetrabutyl titanate with a mass ratio of 1: (3-5) to solution A is added to solution A to obtain solution B;

[0036] S3, adding ytterbium nitrate and holmium nitrate with a mass ratio of 1: (3 to 18) in solution B to obtain solution C during continuous stirring, the mass ratio of solution B to the sum of ytterbium nitrate and holmium nitrate is (3.8 to 5.2 ):1;

[0037] S4, adding bismuth nitrate with a mass ratio of 1: (5.5 to 6.5) to solution C in the process of continuous stirring to obtain solution D;

[0038] S5. Add PVP with a mass fraction of 4-8% to the solution C and stir to prepare an electrospinning precursor solution;

[0039] S6. In the ...

Embodiment 1

[0049] DMF and acetic acid were mixed according to a mass ratio of 1:0.2, and a transparent solution was formed by magnetic stirring; then 0.9ml of tetrabutyl titanate was added and fully dissolved by stirring; 0.027g of holmium nitrate and 0.112g of ytterbium nitrate; after it is fully dissolved, add 1.018g of bismuth nitrate and fully stir to dissolve it, and finally add PVP with a mass fraction of 4%, and obtain an electrospinning precursor solution after magnetic stirring.

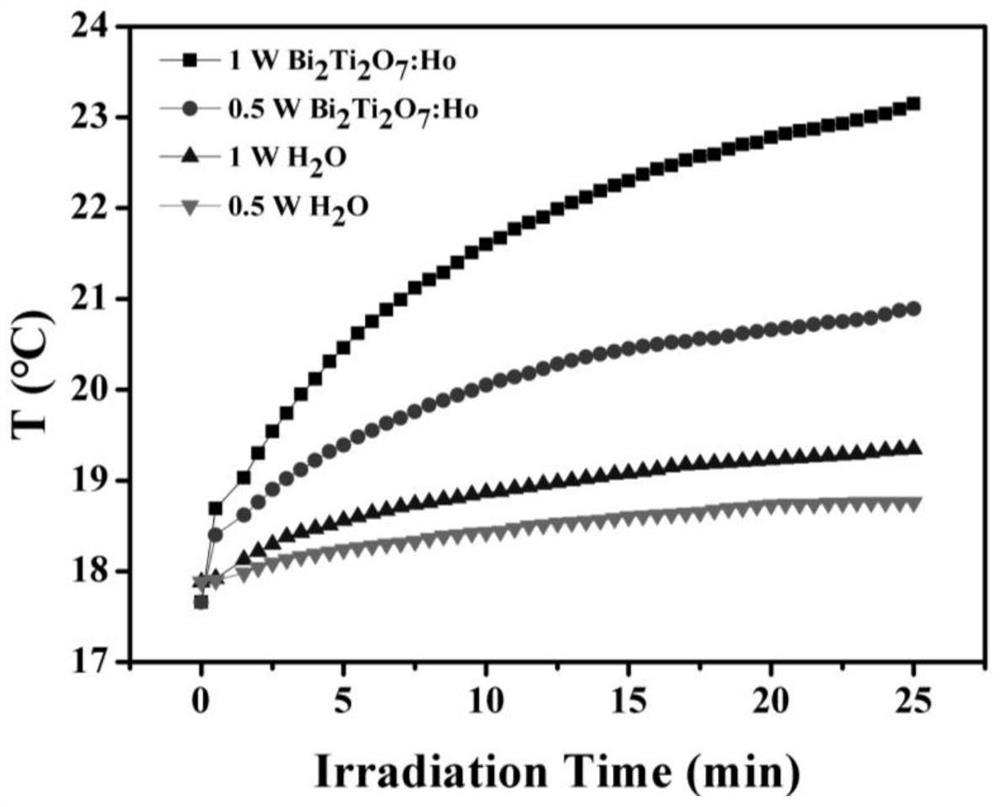

[0050] Under the conditions of control voltage of 15KV and flow rate of 3μl / m, a large amount of nanomaterials appeared on the collector. After the electrospinning was completed, the nanomaterials on the collector were transferred to the muffle furnace and heated at 3°C / min. If the rate is increased to 600°C for 2 hours, the pyrochlore phase Bi with high crystallization performance can be obtained. 2 Ti 2 o 7 : Yb 3+ ,Ho 3+ nanomaterials.

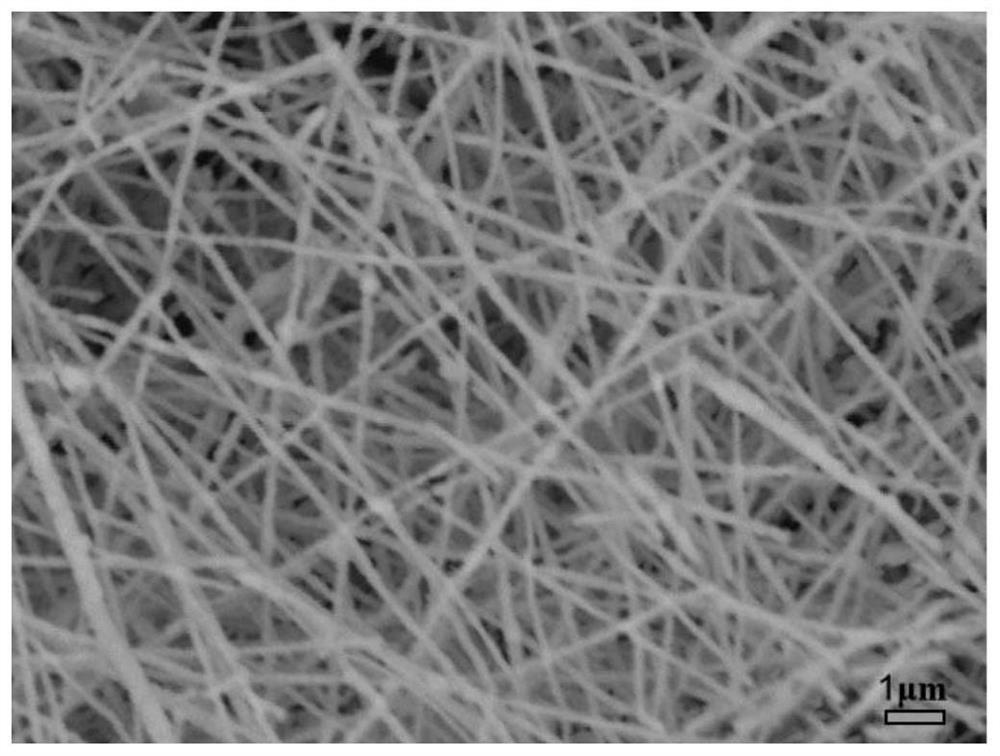

[0051] figure 1 Given the obtained Bi 2 Ti 2 o 7 : Yb...

Embodiment 2

[0053] DMF and acetic acid were mixed according to a mass ratio of 1:0.4, and a transparent solution was formed by magnetic stirring; then 1.0ml of tetrabutyl titanate was added and fully dissolved by stirring; 0.019g of holmium nitrate and 0.12g of ytterbium nitrate; after it is fully dissolved, add 1.018g of bismuth nitrate and fully stir to dissolve it, and finally add PVP with a mass fraction of 5%, and obtain an electrospinning precursor solution after magnetic stirring.

[0054] Under the conditions of control voltage of 15KV and flow rate of 7μl / m, a large amount of nanomaterials appeared on the collector. After the electrospinning was completed, the nanomaterials on the collector were transferred to the muffle furnace and heated at 3°C / min. If the rate is increased to 650°C for 2 hours, the pyrochlore phase Bi with high crystallization performance can be obtained. 2 Ti 2 o 7 : Yb 3+ ,Ho 3+ nanomaterials.

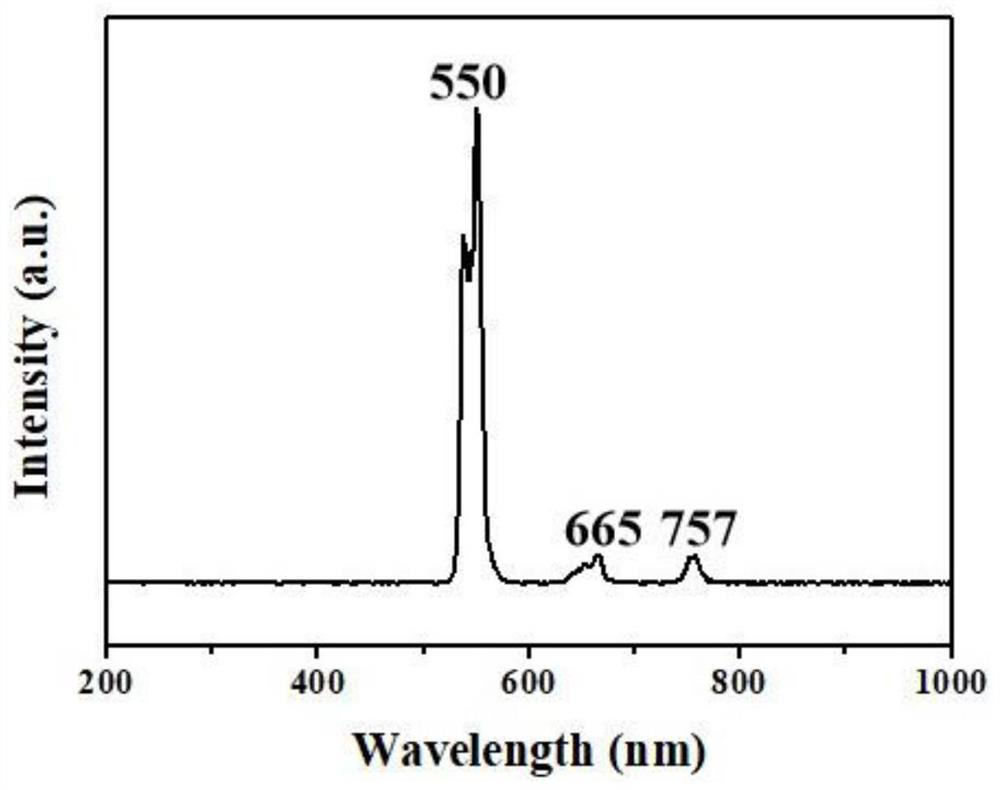

[0055] figure 2 Given that the laser with a wavelength o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com