Replaceable energy dissipation wood structure beam-column joint

A technology for column joints and wood structures, which is used in building components, building structures, and earthquake resistance. performance, reduce maintenance and repair costs, and avoid cross-grain splitting damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

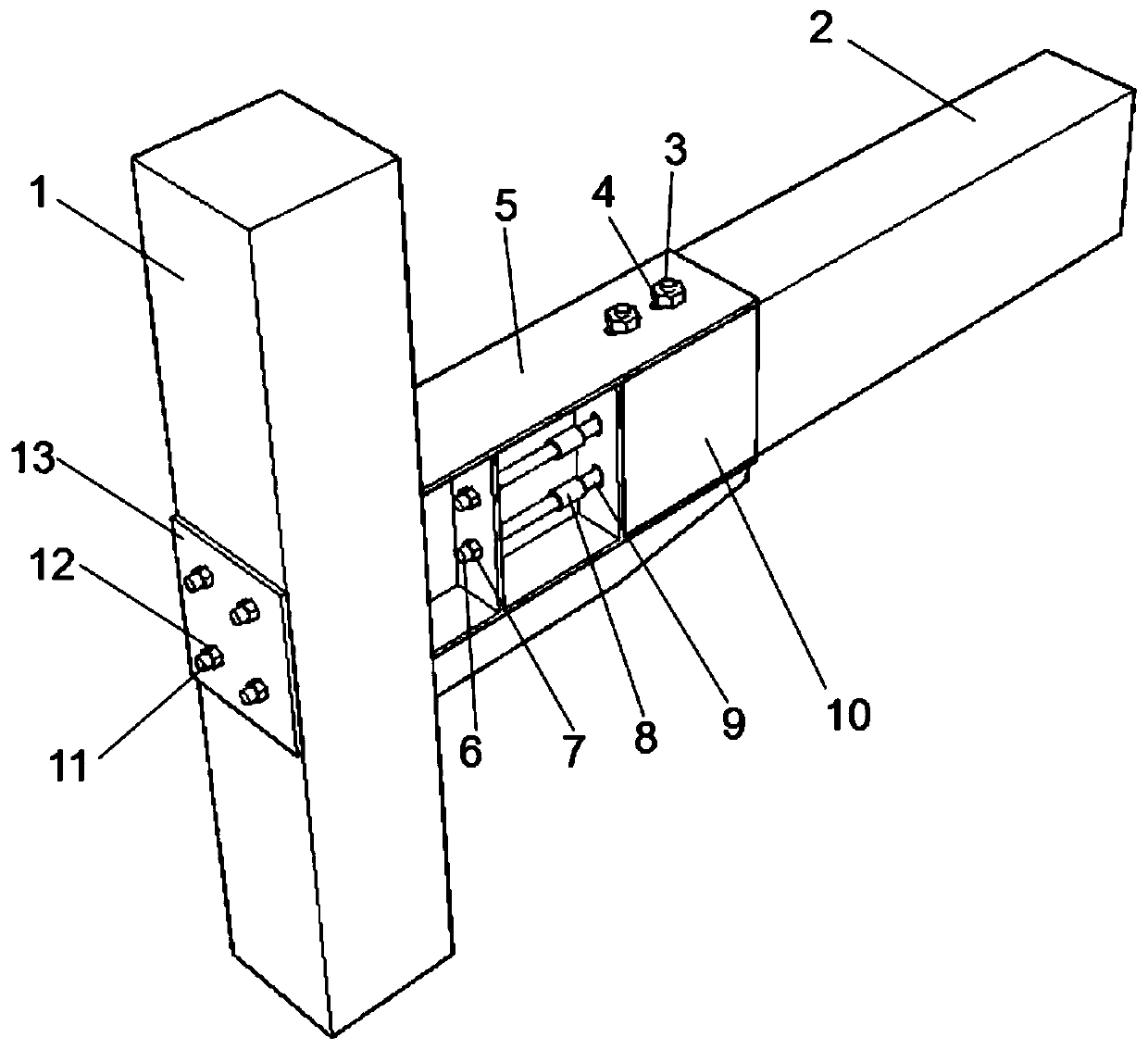

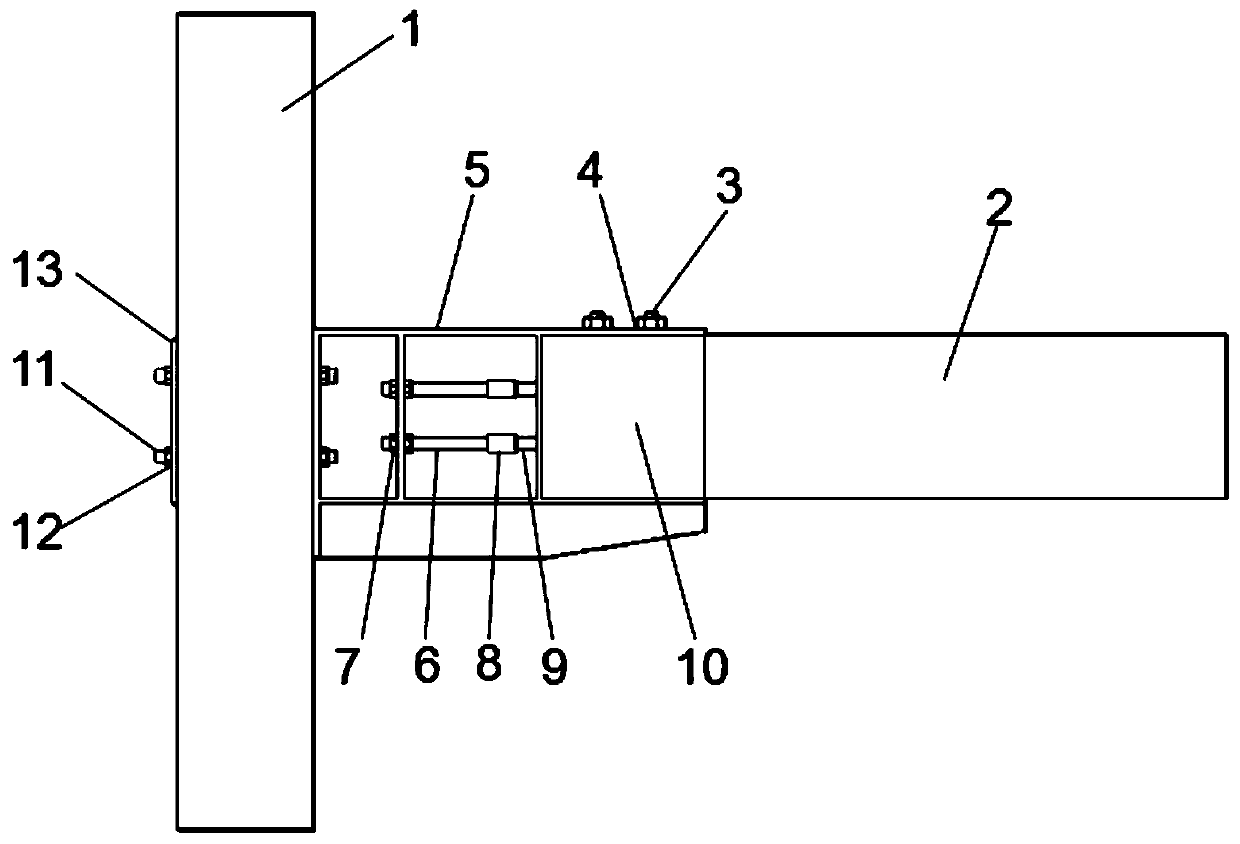

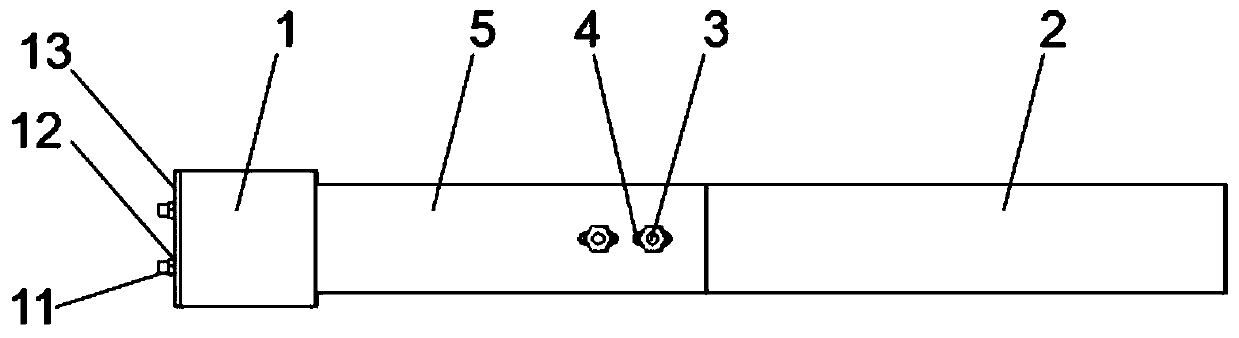

[0038] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a replaceable energy-consuming wooden beam-column joint mainly includes beam-column connector 5, steel plate frame 10, planting reinforcement 9 and shape memory alloy screw 6, and the material of wooden beam 2 and wooden column 1 is log , sawn timber, glued or laminated veneer lumber or other engineered wood. in:

[0039] The beam-column connector 5 is located between the connection ends of the wooden column 1 and the wooden beam 2, refer to Figure 5 , which includes an I-beam, including an I-beam, and a number of vertical steel plates perpendicular to the web are welded between the upper and lower wing plates of the I-beam.

[0040] In order to further facilitate the connection, the end faces of the I-beams are closed by vertical steel plates perpendicular to the web...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com