Folding tooth channel steel for rail transit tunnel and preparation process thereof

A technology for rail transit and preparation process, applied in tunnels, tunnel linings, applications, etc., can solve the problems of mold preparation, high grinding cost, difficult product changeover, complex processing technology, etc., to achieve high bearing capacity and reduce holes. The effect of simple design and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

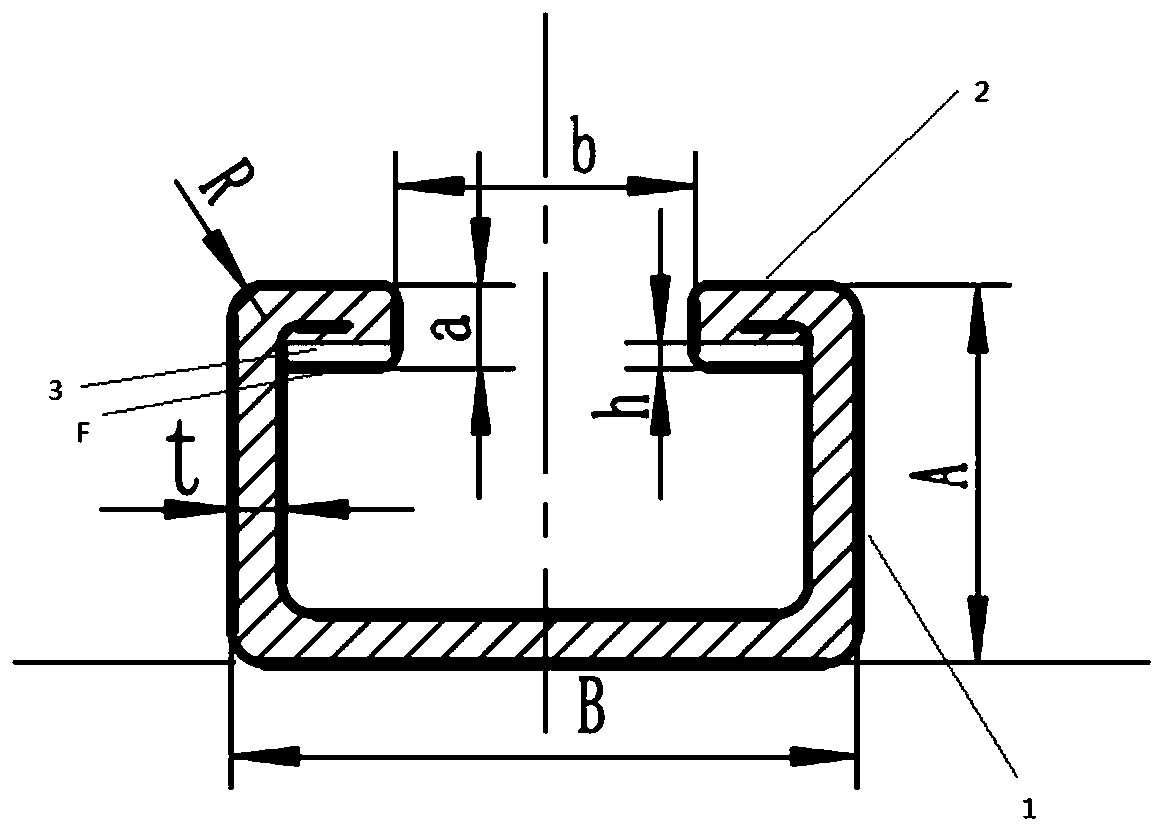

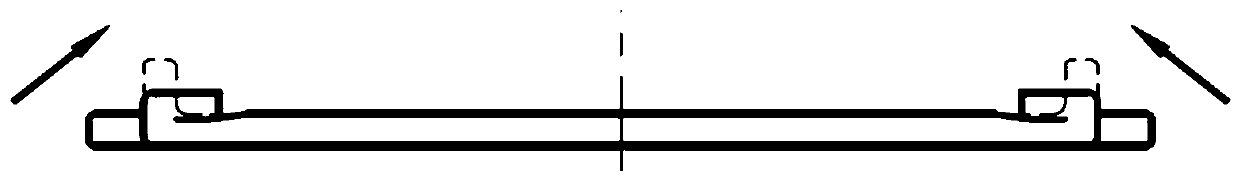

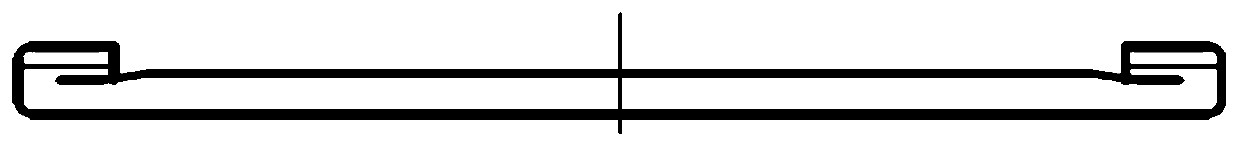

[0028] The folded tooth alveolar steel is formed by bending the strip plate with equal thickness. First, the edge parts on both sides of the strip plate are turned up and pressed to form the tooth-shaped part 3, and then the teeth are pressed on the upper surface F of the tooth-shaped part 3. as attached figure 2 or attached image 3 As shown, then carry out symmetrical vertical bending on both sides of the belt plate to form the supporting part 2, as shown in the attached Figure 5 As shown, finally bend the belt plate upward again to form the support leg 1, so that the support part is horizontal, as shown in the attached Figure 6 shown. The cross-sectional view of the formed folded alveolar steel is a rectangular frame structure with one side open.

[0029] The height A of the formed folded tooth alveolar steel is 23mm; the total width B is 38mm; the opening width b is 18mm; the total height a of the tooth segment is 6mm; the tooth height h is 2mm; the wall thickness t ...

specific Embodiment 2

[0037] The folded tooth alveolar steel is formed by bending the strip plate with equal thickness. First, the edge parts on both sides of the strip plate are turned up and pressed to form the tooth-shaped part 3, and then the teeth are pressed on the upper surface F of the tooth-shaped part 3. as attached figure 2 or attached image 3 As shown, then carry out symmetrical vertical bending on both sides of the belt plate to form the supporting part 2, as shown in the attached Figure 5 As shown, finally bend the belt plate upward again to form the support leg 1, so that the support part is horizontal, as shown in the attached Figure 6 shown. The cross-sectional view of the formed folded alveolar steel is a rectangular frame structure with one side open.

[0038] The height A of the formed folded tooth alveolar steel is 25mm; the total width B is 50mm; the opening width b is 22mm; the total height a of the tooth segment is 6mm; the tooth height h is 2mm; the wall thickness t ...

specific Embodiment approach 3

[0046] The folded tooth alveolar steel is formed by bending the strip plate with equal thickness. First, the edge parts on both sides of the strip plate are turned up and pressed to form the tooth-shaped part 3, and then the teeth are pressed on the upper surface F of the tooth-shaped part 3. as attached figure 2 or attached image 3 As shown, then carry out symmetrical vertical bending on both sides of the belt plate to form the supporting part 2, as shown in the attached Figure 5 As shown, finally bend the belt plate upward again to form the support leg 1, so that the support part is horizontal, as shown in the attached Figure 6 shown. The cross-sectional view of the formed folded alveolar steel is a rectangular frame structure with one side open.

[0047] The height A of the formed folded tooth alveolar steel is 36mm; the total width B is 53mm; the opening width b is 22mm; the total height a of the tooth segment is 7mm; the tooth height h is 3mm; the wall thickness t ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com