Multi-layer corrugated pipe and connecting pipe connecting structure and connecting method of connecting structure

A connection structure and corrugated pipe technology, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, passing components, etc., can solve problems such as leakage, failure of expansion joints, and unknowable inner connection status, etc., to achieve long life , good sealing, suitable for mass promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

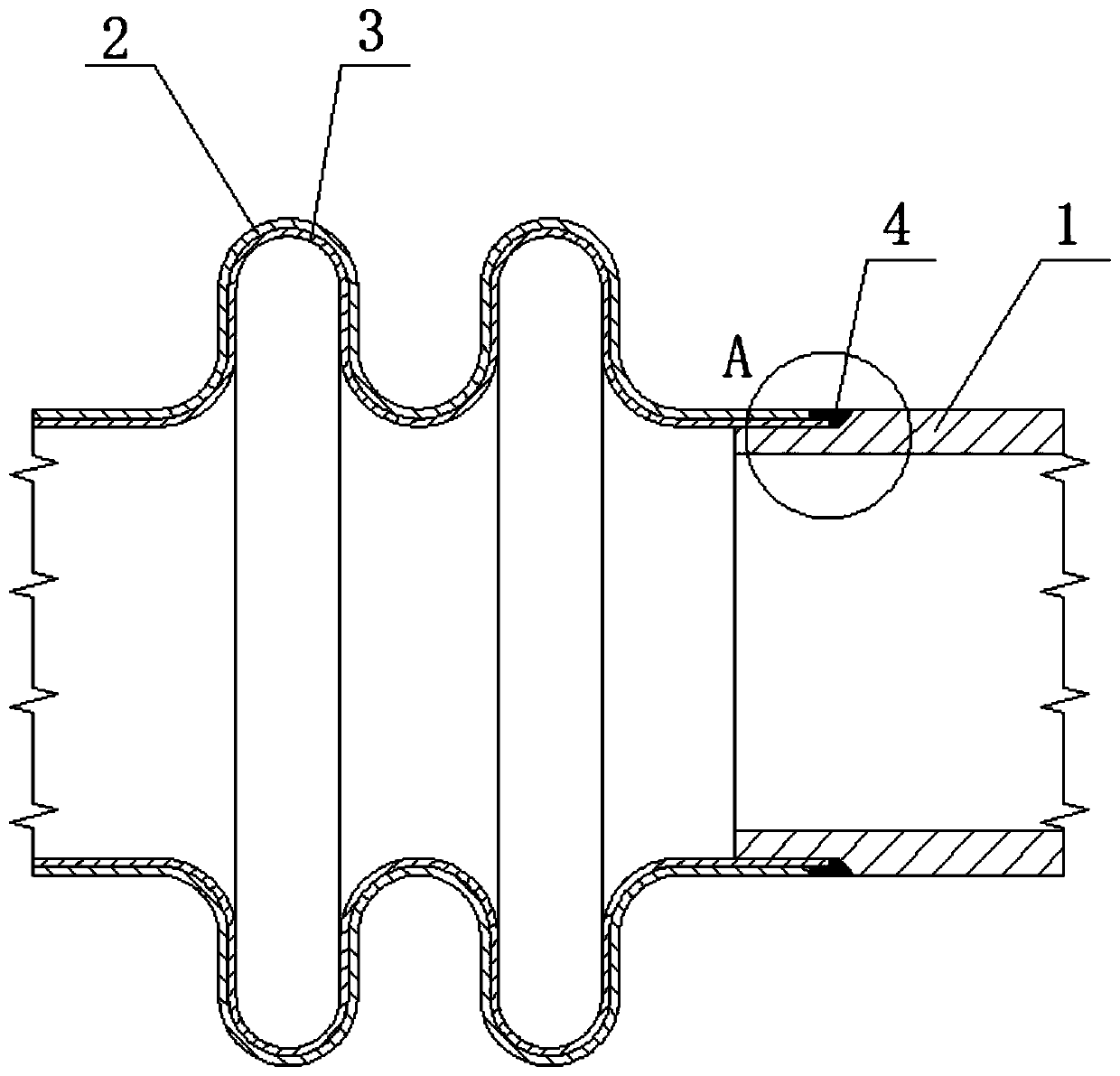

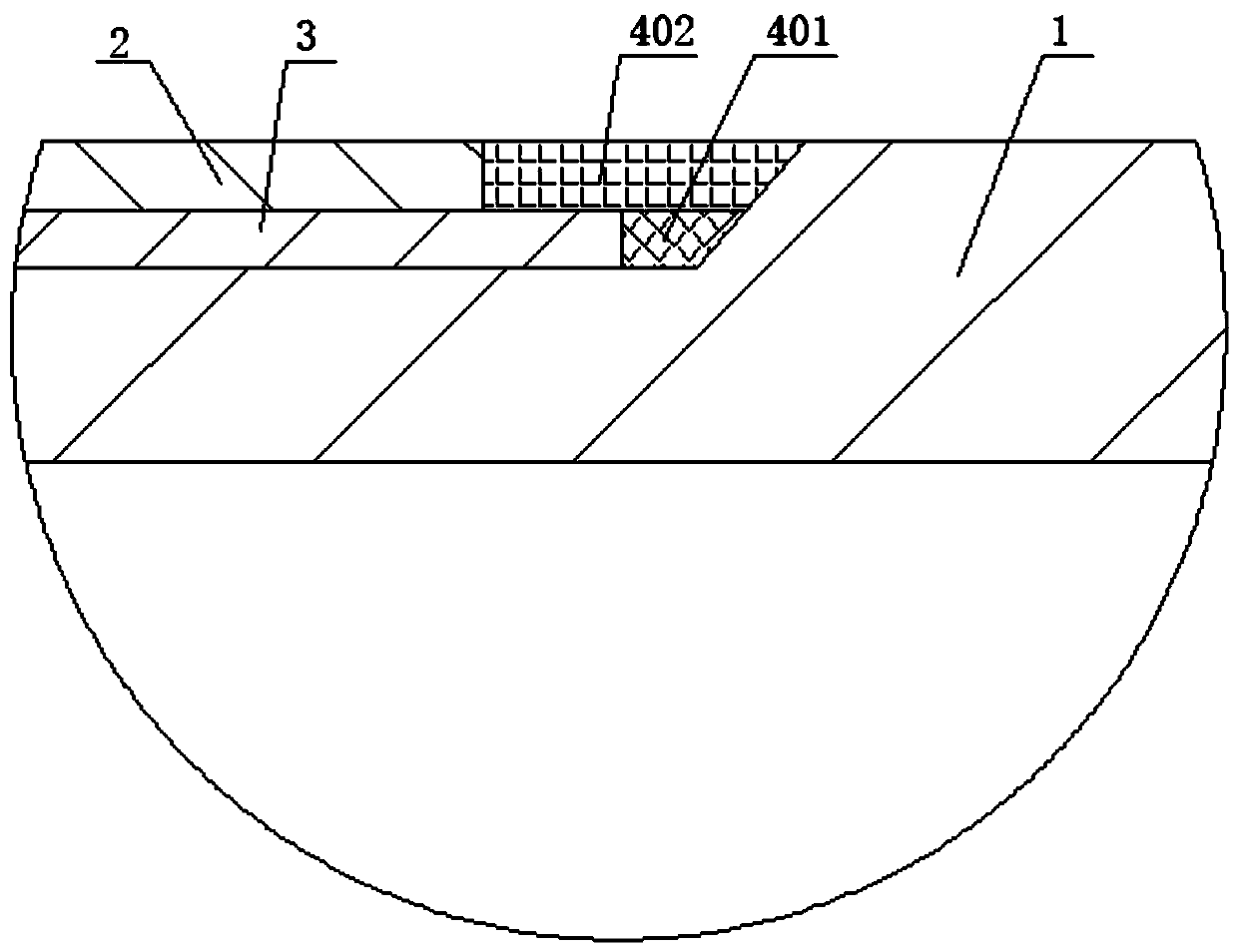

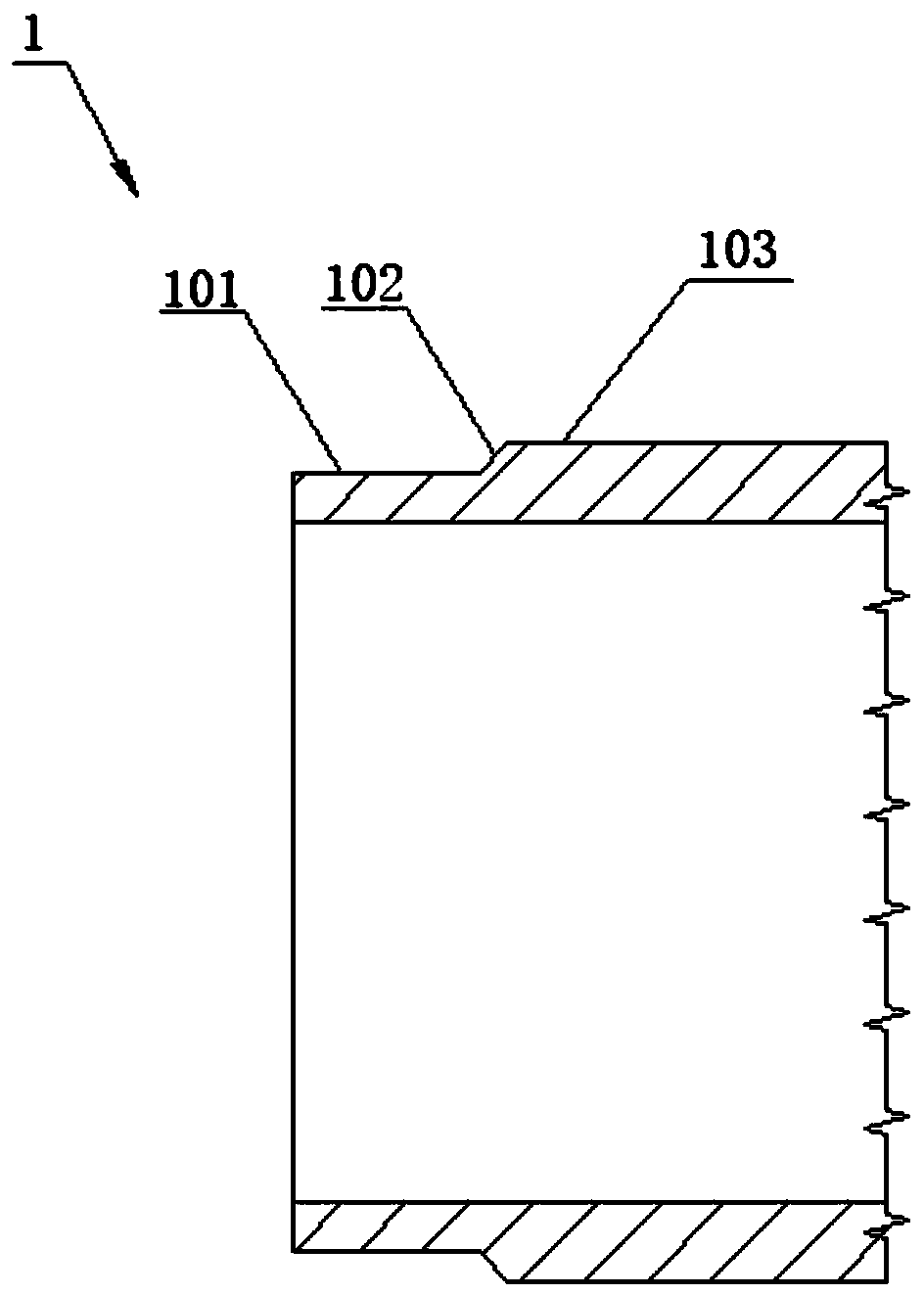

[0053] Embodiment two, such as Figure 4 with Figure 5 As shown, the multi-layer corrugated pipe and the connecting pipe 1 are connected by interpolation. In the first step of material preparation, prepare the multi-layer corrugated pipe with a stepped inner ring at the end of the straight section, prepare the connecting pipe 1 with a stepped inner ring at the end, and repeat the first step. From the second step to the seventh step, starting from the welding connection between the outermost layer of the multi-layer corrugated pipe and the connecting pipe 1, until the welding of the innermost layer of the corrugated pipe and the connecting pipe 1 is completed and the inspection is completed.

[0054] The invention has the advantages of simple operation, good connection sealing performance of pipe fittings, long service life, wide applicability and easy popularization and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com