Flaw detection device of round pipe type steel member

A flaw detection and detection technology for steel components, which is applied to measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. Accurately measure the boundary and length of the weld, so as to improve the detection efficiency, improve the marking accuracy, and improve the marking efficiency and marking accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

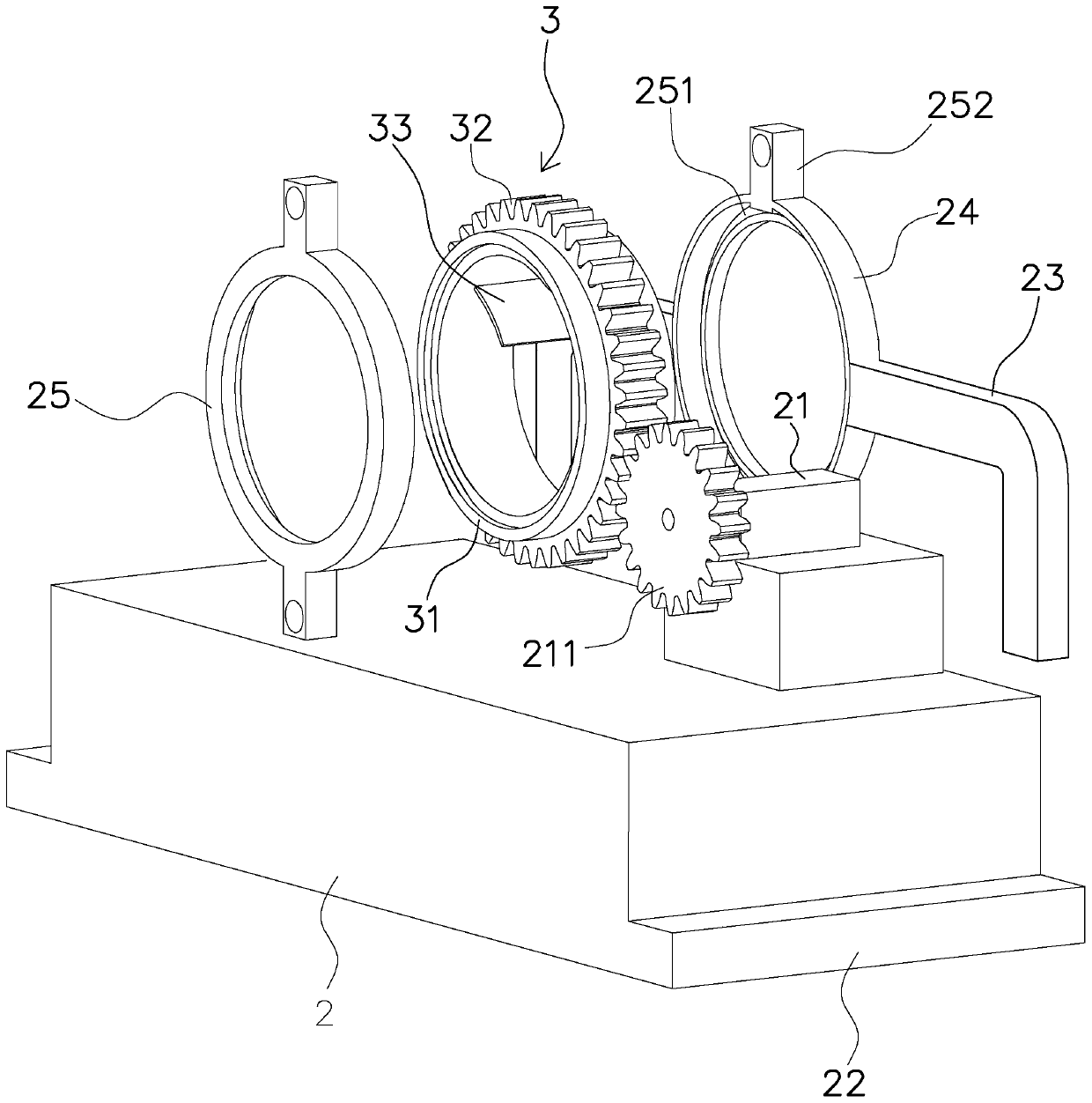

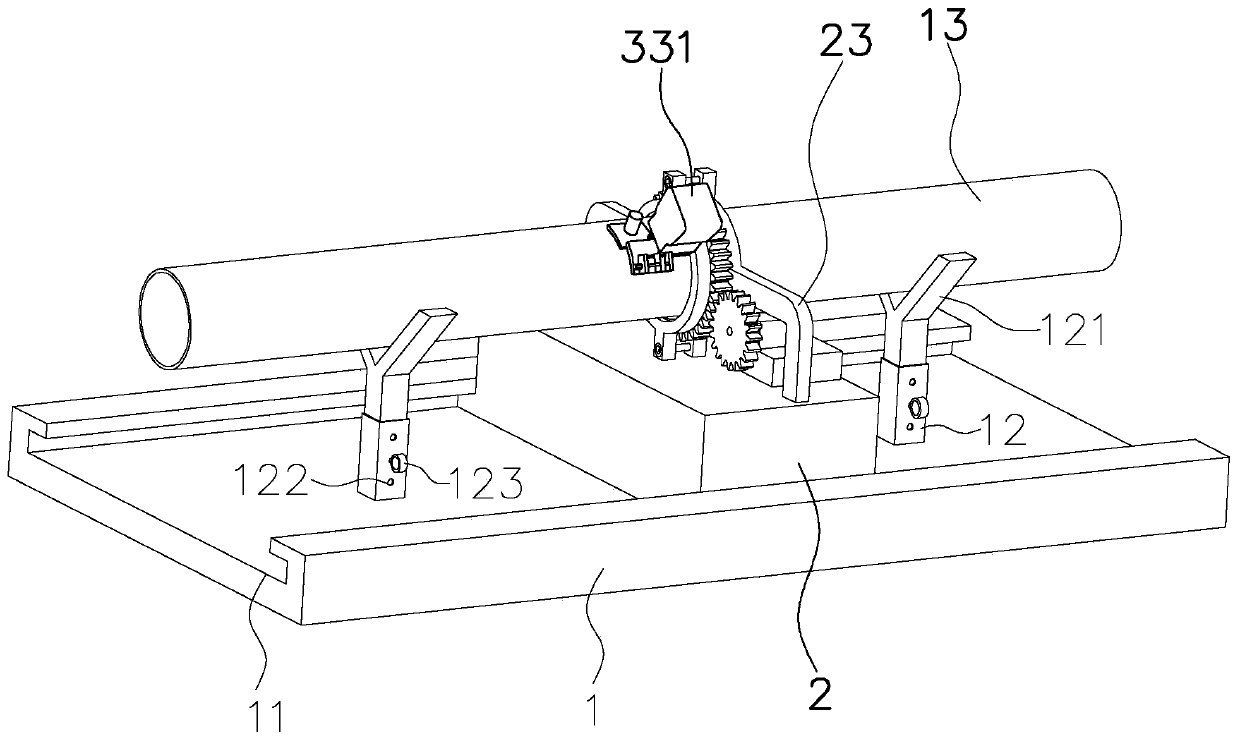

[0040] refer to figure 1 and figure 2 , is a flaw detection device for a circular tubular steel member disclosed in the present invention, comprising a base plate 1 on which an inverted T-shaped chute 11 is opened. In this embodiment, on both sides of the length of the chute 11, there are support cylinders 12 vertically fixed on the base plate 1, and a Y-shaped support body 121 is set inside the support cylinder 12, and the support body 121 The bifurcated portion protrudes upwards out of the support cylinder 12 and the carrier 121 can slide up and down relative to the support cylinder 12 .

[0041] refer to figure 1 and figure 2 A plurality of positioning holes 122 arranged vertically are arranged at equal intervals on one side of the support cylinder 12 . In this embodiment, an annular pin 123 is pierced through the positioning hole 122 .

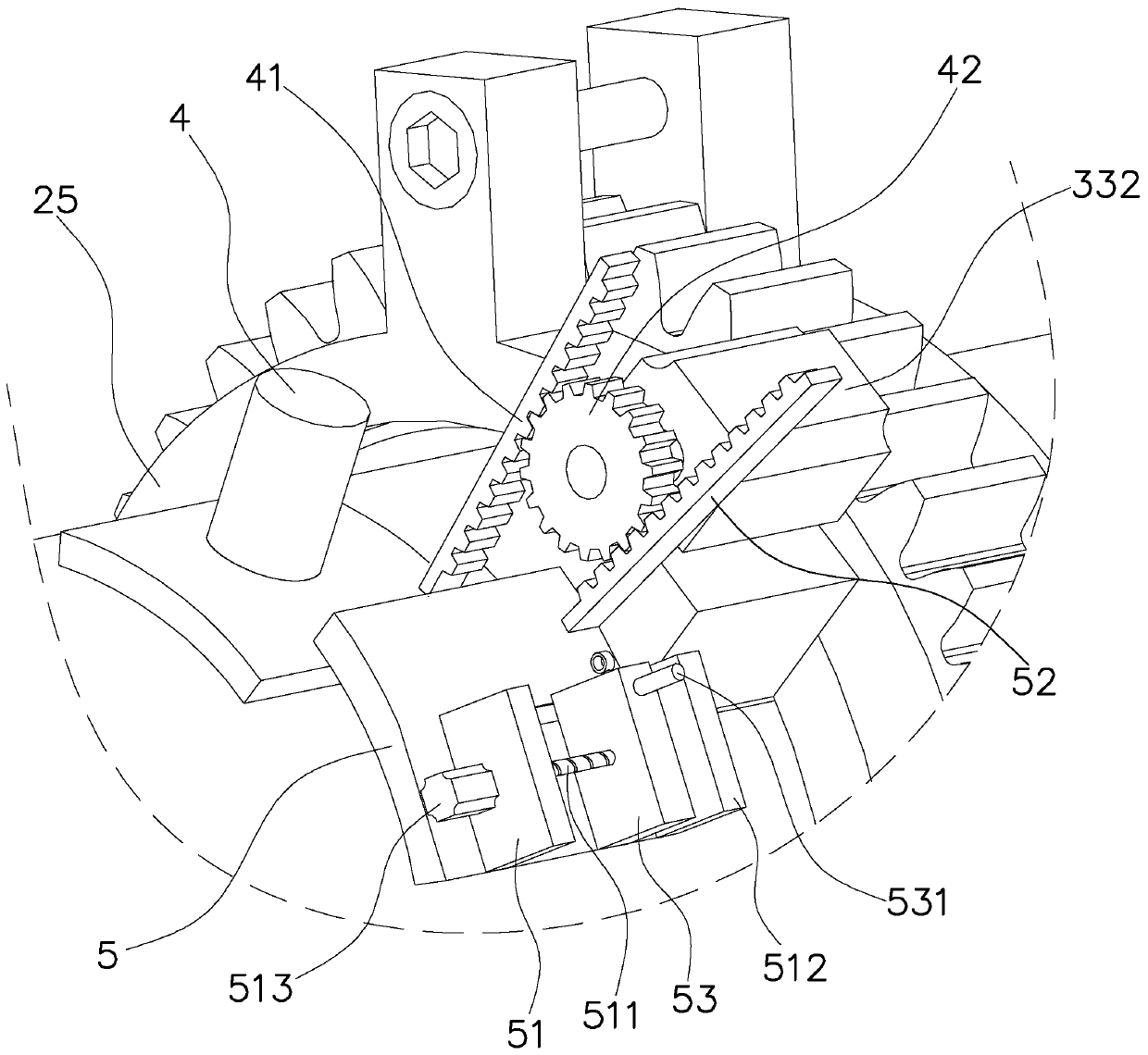

[0042] refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com