Method for rapidly removing organic solderable protective agent and oxide from substrate

An oxide and solderability technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as different functions, low machine productivity, and complicated flux pre-cleaning process, and achieve heat release. Small, no security risk effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

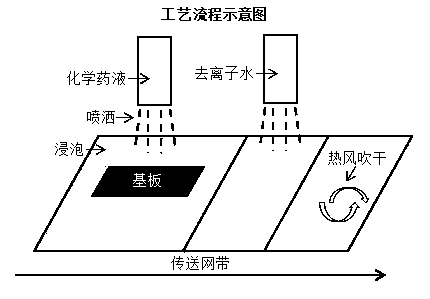

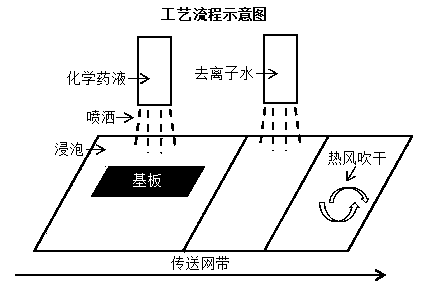

[0023] The invention discloses a method for quickly removing substrate organic solderability preservatives and oxides, such as figure 1 As shown, the method includes the following steps:

[0024] S1: feeding;

[0025] Place the material to be cleaned on the conveyor belt to start the cleaning process;

[0026] S2: Spray soaking;

[0027] Spray and infiltrate the material to be cleaned with a weak alkaline liquid, and fully neutralize the acid-base reaction with the organic solderable protective agent and oxide on the metal surface of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com