Engine lubricant composition

A lubricant composition, engine technology, applied in the direction of lubricating composition, additives, petroleum industry, etc., can solve the problems of improving engine cleanliness, not describing polyalkylene glycol, not increasing gasoline or diesel fuel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

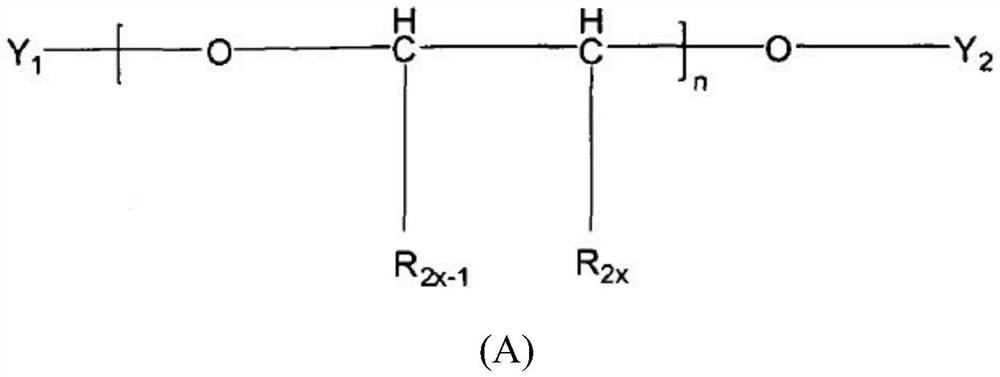

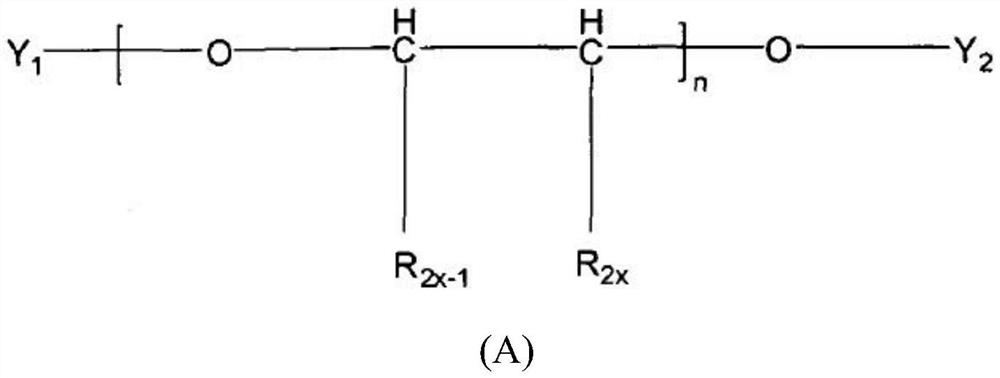

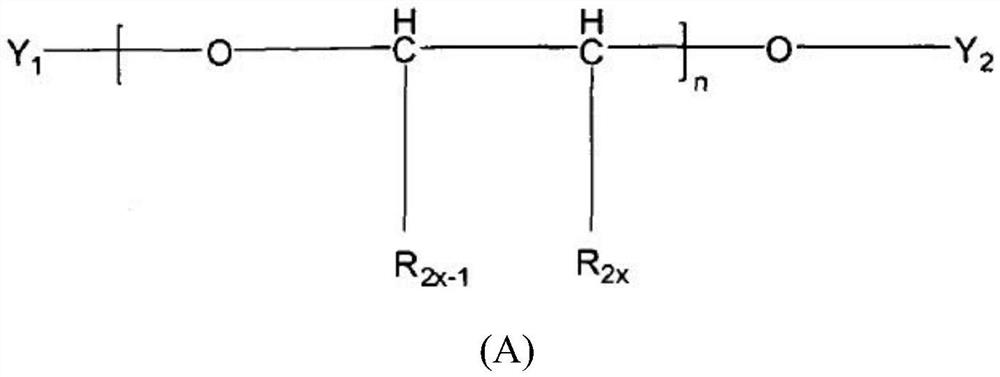

Method used

Image

Examples

Embodiment 1

[0171] The control composition T was prepared as follows 1 and composition L 1 and L 2 :

[0172] - mixtures of Group III base oils,

[0173] - Additive package including ZnDTP type antiwear additives, amino and phenolic antioxidants, succinimide type dispersants, salicylate type detergents,

[0174] - molybdenum dithiocarbamate (MoDTC),

[0175] - a star-shaped hydrogenated, styrene / isoprene (HIS) viscosity index improver polymer having a mass Mw equal to 498700 (measured according to standard ASTM D5296), having a mass Mn equal to 325900 (measured according to standard ASTM D5296 ), having a polydispersity index equal to 1.5.

[0176] - polyalkylmethacrylate (PAMAd) grafted with vinylpyrrolidone units, having a mass Mw equal to 206900 (measured according to standard ASTM D5296), having a mass Mn equal to 75320 (measured according to standard ASTM D5296), having equal to a polydispersity index of 2.7,

[0177] - BO / PO (butylene oxide / propylene oxide) PAG with a mass ra...

Embodiment 2

[0194] A control composition T was prepared from the same ingredients as above, except that another polyalkylene glycol was used as follows 2 and composition C 1 -C 4 : BO / PO PAG with a mass ratio of 50 / 50, a KV100 equal to 4 cSt (measured according to standard ASTM D445) and a molar mass equal to 505 g / mol (measured according to standard ASTM D4274).

[0195] The proportions in mass percent of the different ingredients are shown in Table III below. The ratio of the mixture of base oil and viscosity index improver polymer is adjusted such that for grade 5W-30, the lubricant composition T 2 、C 1 -C 4 have equal viscosity.

[0196] Then, the lubricant composition T is measured on the driven DW10C test engine 2 、C 1 -C 4 "Fuel Economy" gain. The conditions for this test are as follows:

[0197] The engine is driven by a generator making it possible to enforce a rotational speed between 750 and 3000 rpm, while a torque sensor makes it possible to measure the frictional t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com