A Processing Fixture for Precisely and Quickly Extruding the Inclined Hole of Valve Seat

A technology of hydraulic extrusion and valve seat, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inconsistent factory conditions, high part rejection rate, large capital investment, etc., and achieve high manufacturing precision , Simple installation, and the effect of improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

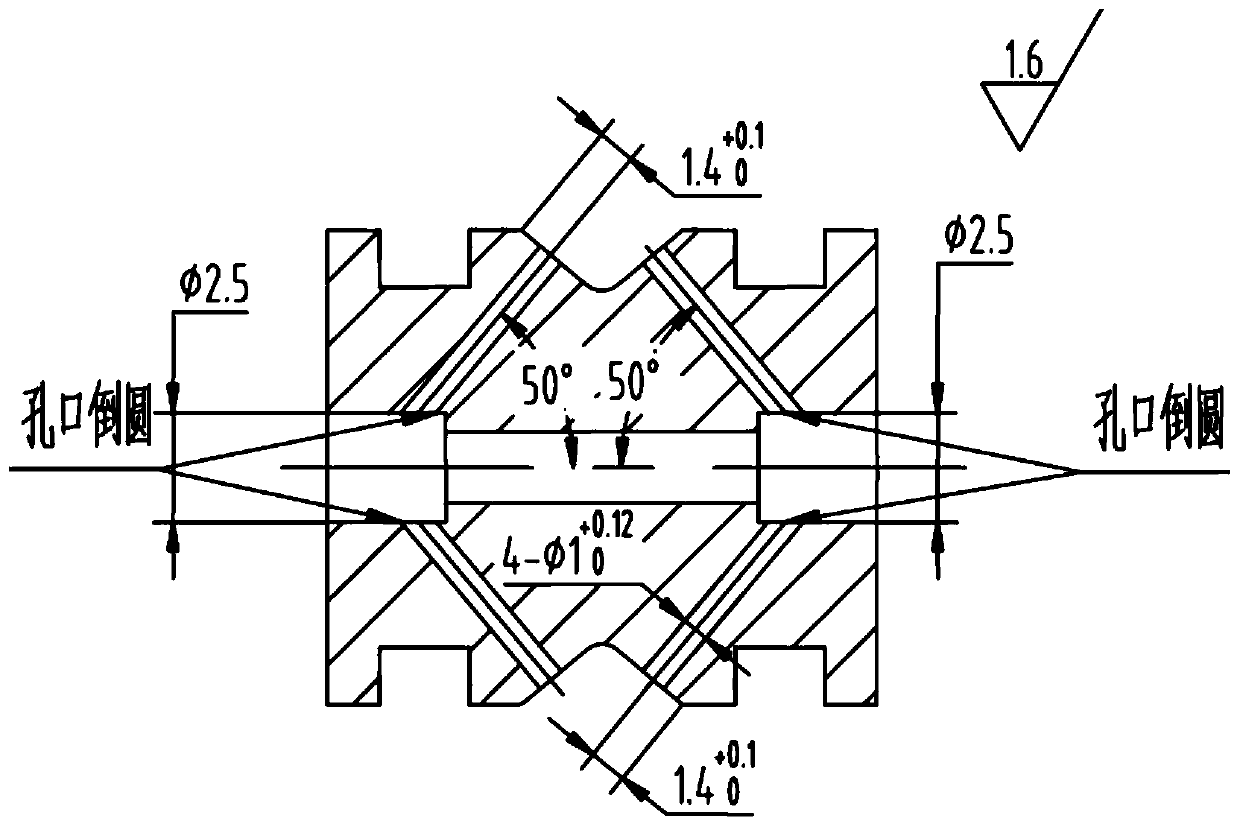

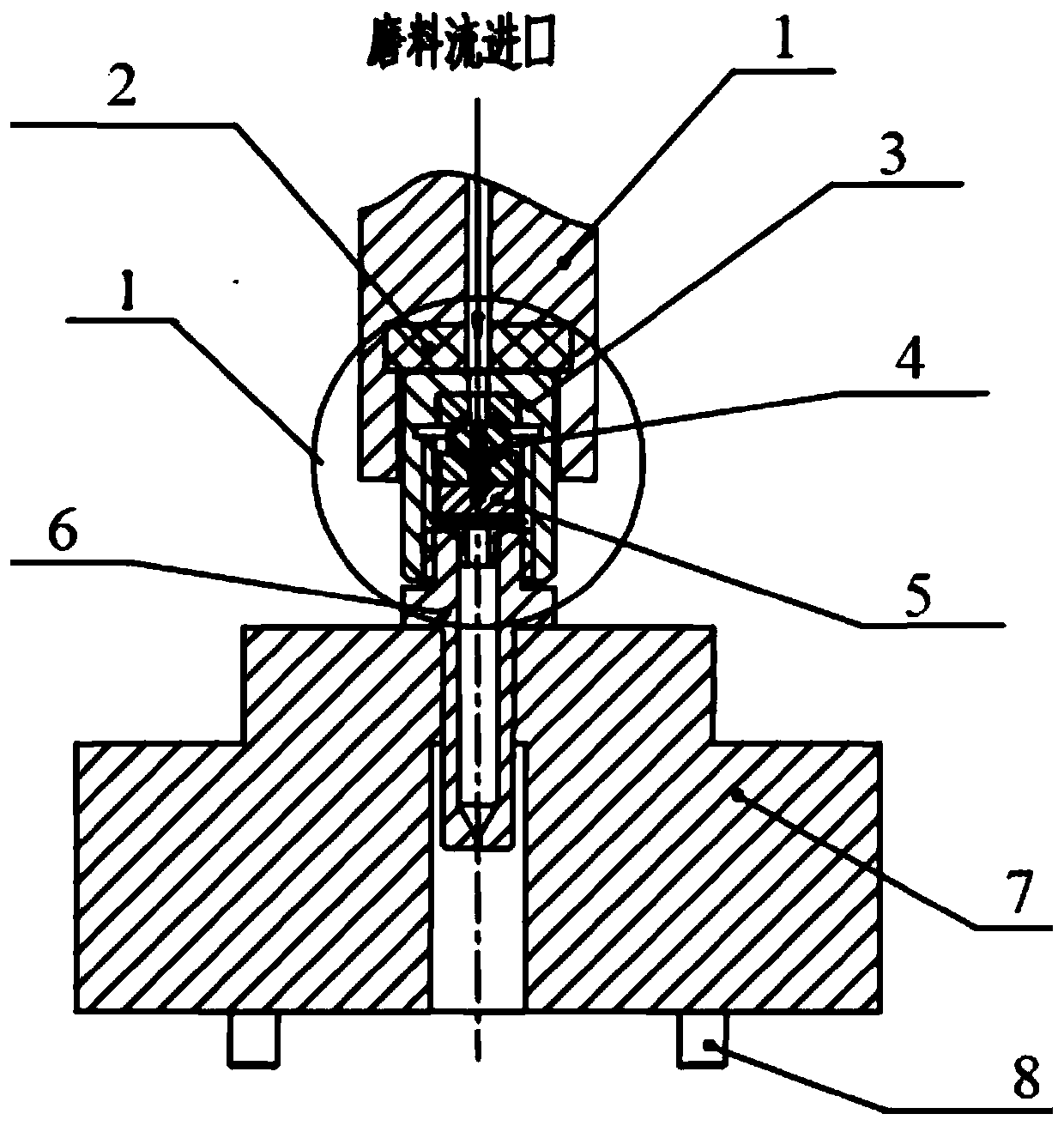

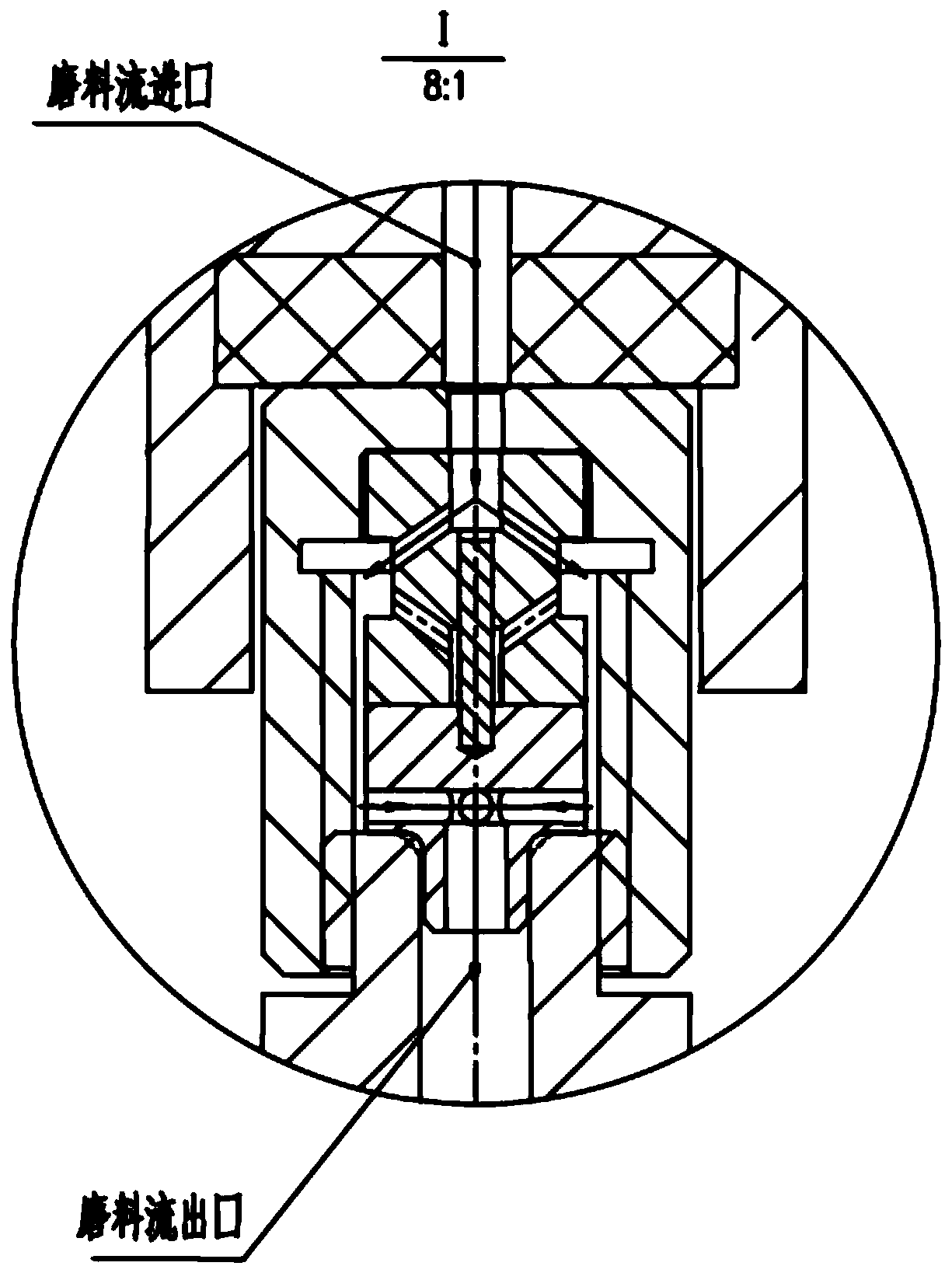

[0034] refer to Figure 2 to Figure 8 As shown, this fixture is an assembled and combined structure, including: guide sleeve 3, first positioning pin 4, positioning valve 5 and liquid guide valve 6, guide sleeve 3 is a sleeve-shaped structure with a hole in the center of the upper end surface, and the inside of guide sleeve 3 Install the valve seat, the middle hole of the valve seat is coaxial with the through hole of the guide sleeve, the positioning valve 5 is arranged under the valve seat, and the liquid guide valve 6 is arranged below the positioning valve 5, and the liquid guide valve 6 is threadedly connected with the inner cylinder wall of the guide sleeve 3; The hole in the seat includes an upper hole and a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com