A paper belt type degreasing treatment filtration system and method with pre-coating function

A degreasing treatment and filtration system technology, applied in the separation method, filtration separation, filtration circuit, etc., can solve the problems of difficulty in guaranteeing the cleanliness of degreasing liquid, increasing the difficulty of wastewater treatment, and large consumption of degreasing liquid, so as to improve the recycling rate, The effect of solving cleanliness and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

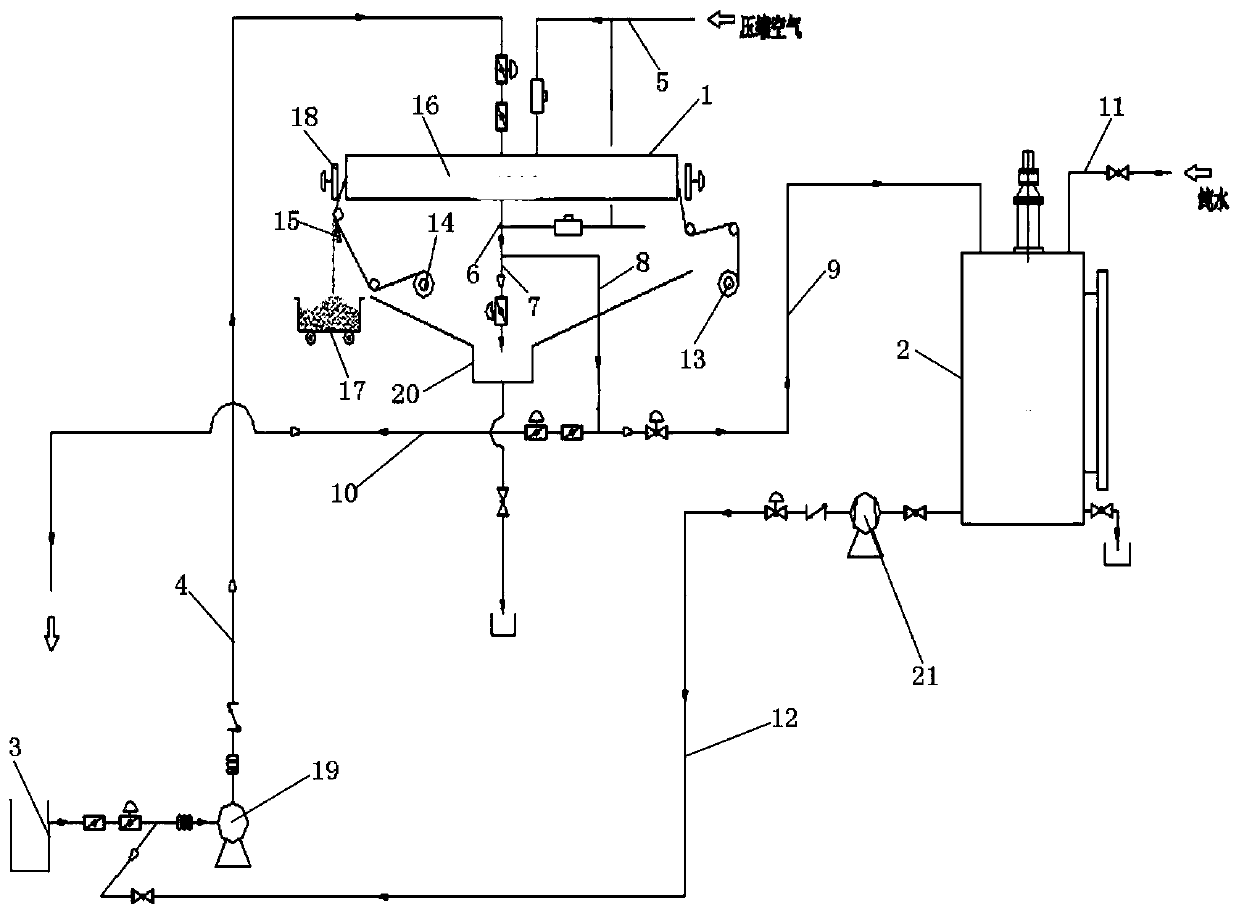

[0020] Such as figure 1 As shown, a paper strip type degreasing treatment filter system with pre-coating function includes a filter chamber 1, a dosing mixer 2, an lye tank and an lye tank 3, and the lye in the lye tank is used for strip steel surface After cleaning, it is discharged into the lye tank, and the lye tank is connected with the liquid inlet of the filter chamber through the lye inlet pipe 4, and the lye inlet pipe is provided with a pressurizing pump 19, which is lifted and pressurized by the booster pump to filter The air inlet of the chamber is connected with the compressed air source through the air inlet pipe 5, the liquid discharge port at the bottom of the filter chamber is connected with the liquid discharge main pipe 6, and the liquid discharge main pipe is respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com