A method of using an adjustable motor cooling device

A motor cooling and adjustable technology, applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., can solve the problem of not being able to adjust according to the actual situation, and achieve the effect of good heat dissipation, enhanced heat dissipation, and smooth air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

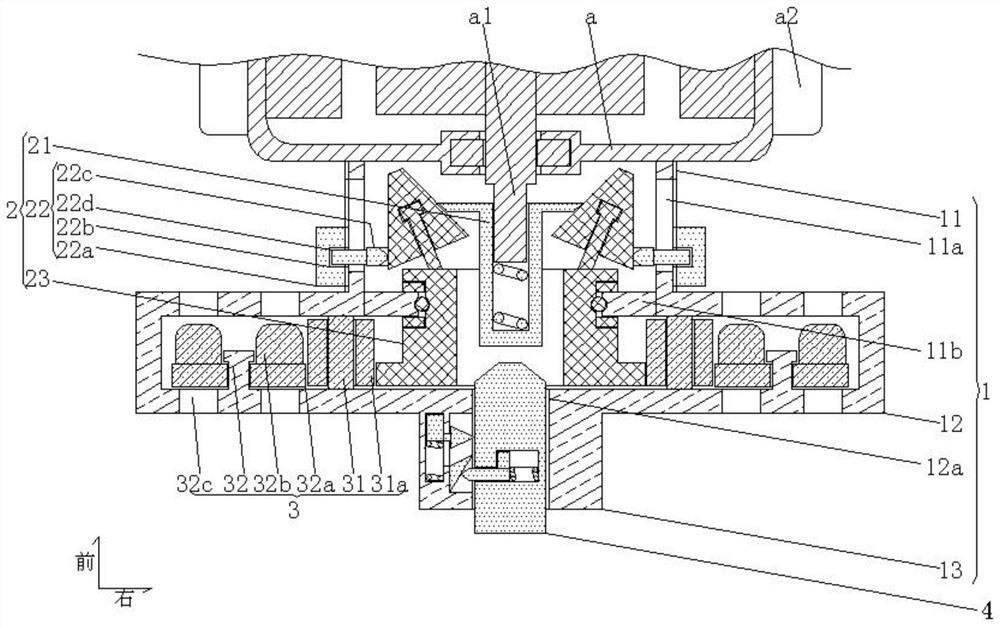

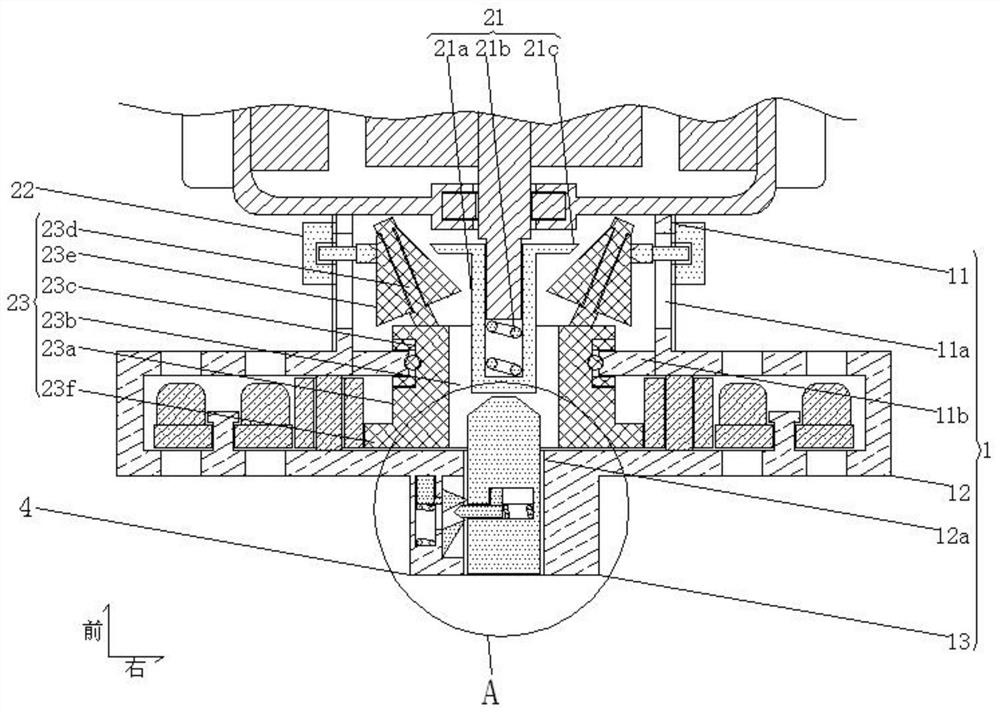

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings.

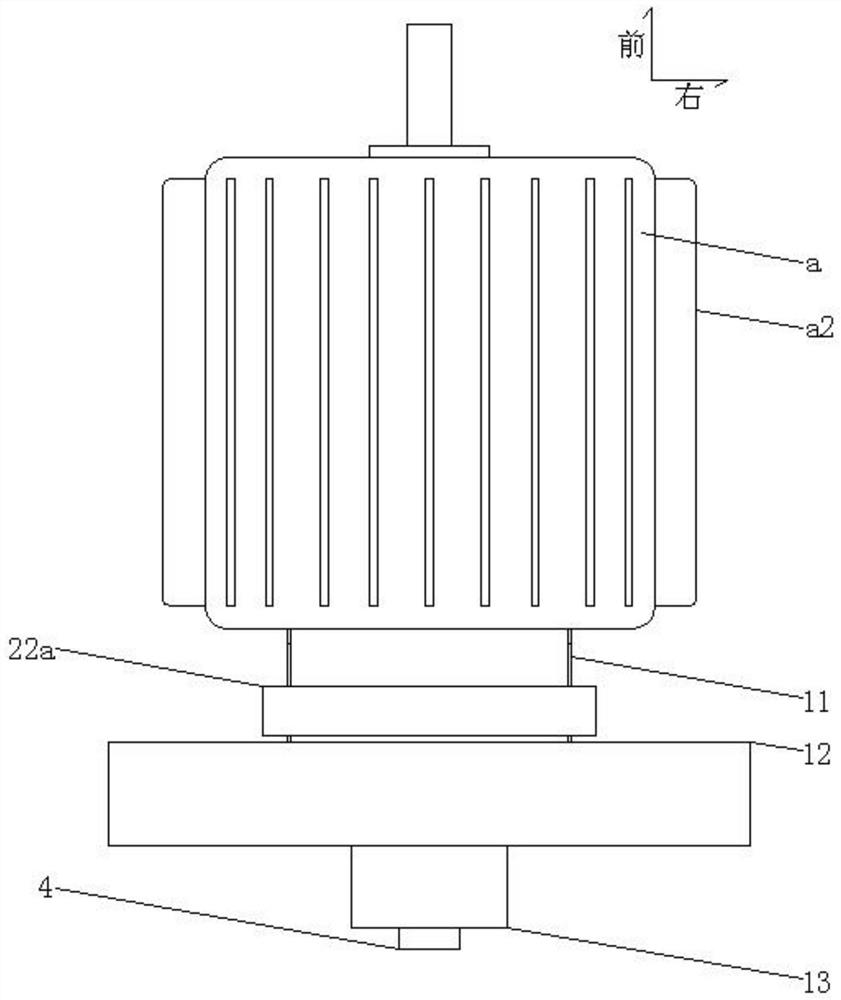

[0059] A method for using an adjustable motor cooling device, the motor cooling device is installed on the rear end of the motor body a, the rear end of the output shaft of the motor body a is formed with a rectangular insertion rod a1, and the outer wall of the motor body a is uniformly distributed along the circumference Axially arranged heat sink a2 is characterized in that:

[0060] The motor cooling device includes a device housing 1, a transmission device 2, a blowing device 3, and an opening and closing device 4;

[0061] The device housing 1 is arranged behind the motor body a to provide structural support for the transmission device 2, the blowing device 3, and the opening and closing device 4. The device housing 1 includes:

[0062] The externally threaded cylinder 11 is arranged at the rear end of the motor body a, and the peripheral side wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com