A chopper amplification circuit adopting a negative impedance compensation technology

A technology of amplifying circuits and negative impedance, which is applied in the field of analog circuit design, can solve problems such as high input impedance, boost, and affect circuit stability, and achieve high input impedance, expand application prospects, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

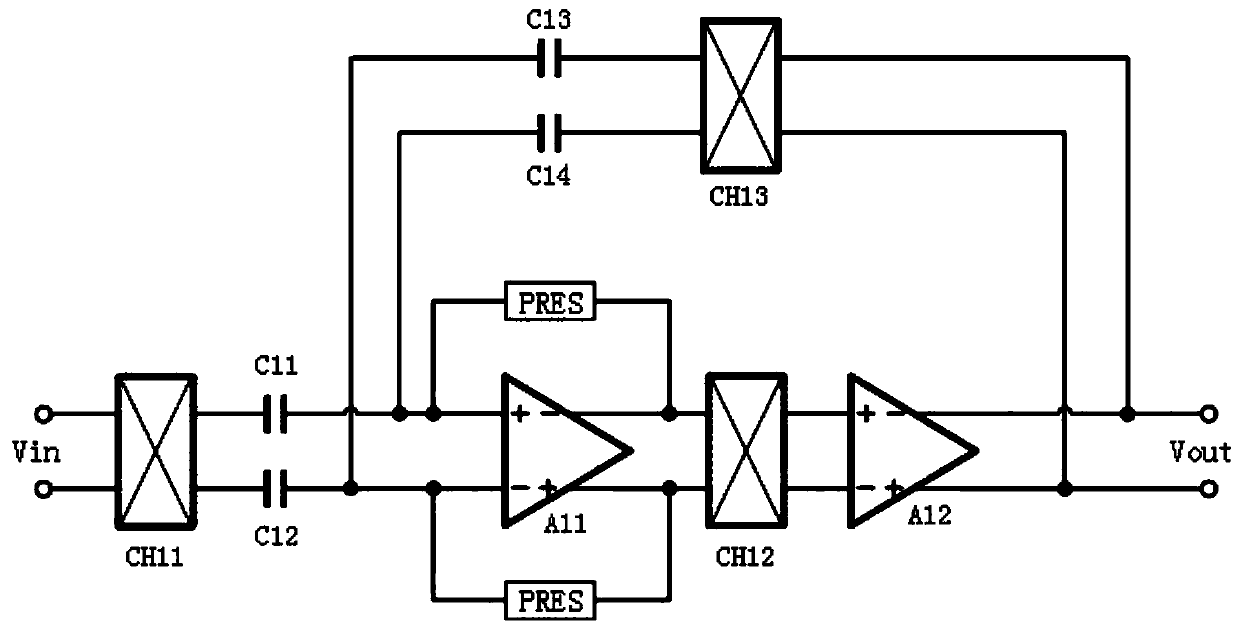

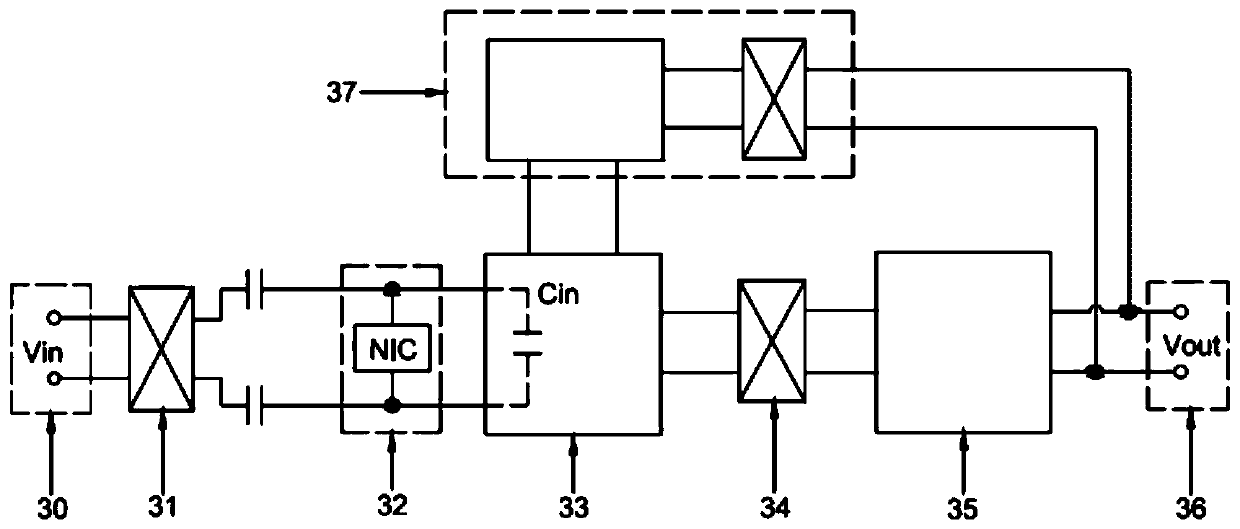

[0053] Such as Figure 5 As shown, the first-stage amplifying circuit 33 includes a third operational amplifier A3, a third pseudo-resistor R3, a fourth pseudo-resistor R4, a fifth pseudo-resistor R5, and a sixth pseudo-resistor R6; the third operational amplifier A3 includes a corresponding first non-inverting input terminal and a first inverting input terminal, a corresponding second non-inverting input terminal and a second inverting input terminal, and also includes a positive output terminal and a negative output terminal; the first One of the output terminals of the stage chopping switch 31 is connected to the first inverting input terminal through the input capacitor, and the second output terminal is connected to the second non-inverting input terminal through the input capacitor, and the positive output terminal is passed through the first inverting input terminal in turn. The second-stage chopper switch 34, the second-stage amplifying circuit 35 and the negative feed...

Embodiment 2

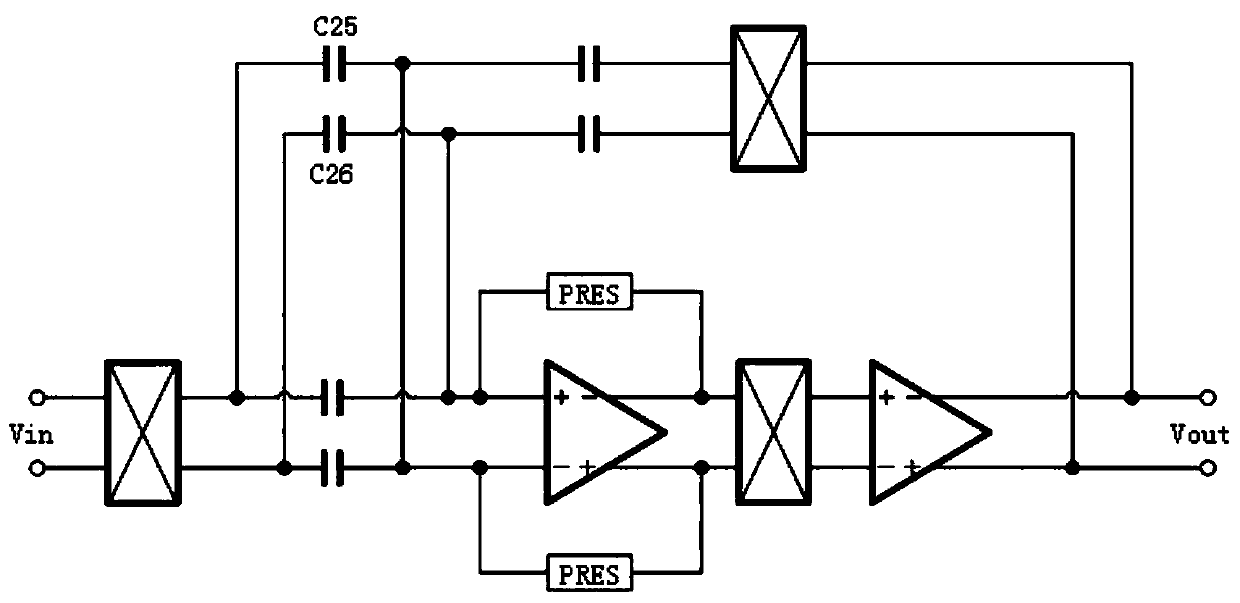

[0056] Such as Image 6 As shown, the first-stage amplifying circuit 33 includes a fourth operational amplifier A4, a fifth operational amplifier A5, a seventh dummy resistor R7, an eighth dummy resistor R8, a ninth dummy resistor R9 and a tenth dummy resistor R10; The non-inverting input terminal of the fourth operational amplifier A4 is sequentially connected in series with the seventh pseudo-resistor R7 and the eighth pseudo-resistor R8, and then connected to the inverting input terminal of the fifth operational amplifier A5, and the seventh pseudo-resistor R7 and the eighth pseudo-resistor A common-mode voltage input terminal is connected between R8, and the output terminal of the fourth operational amplifier A4 passes through the second-stage chopping switch 34, the second-stage amplifying circuit 35 and the negative feedback unit in turn, and then connects the non-phase of the fifth operational amplifier A5. The input terminal is also connected to the inverting input ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com