Panel body, space partition device, furniture with top board, and manufacturing method for panel body

A panel, one-sided technology, applied in the production of furniture cover, lamination device, furniture cover panel, etc., can solve the problem of inorganic matter and other problems of office workers, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0083]

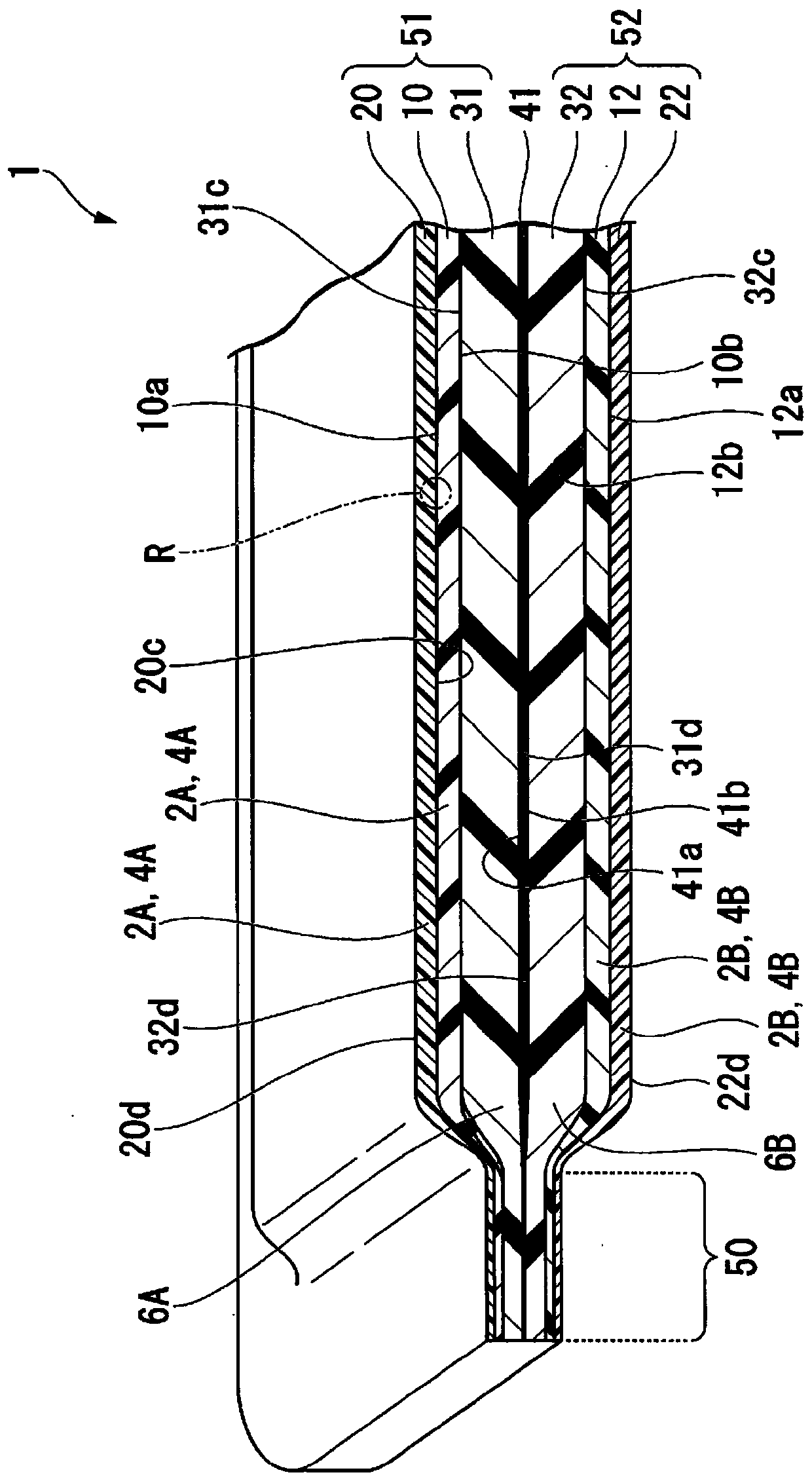

[0084] Such as Figure 1A , Figure 1B As shown, the panel body 1 of the first embodiment of the present invention is a panel body for dividing a space such as an office space not shown, and includes: a buffer layer (first buffer layer) including a fibrous base material 2A ) 51, a buffer layer (second buffer layer) 52, and a functional sheet 41 disposed between the buffer layers 51, 52 and having a predetermined function.

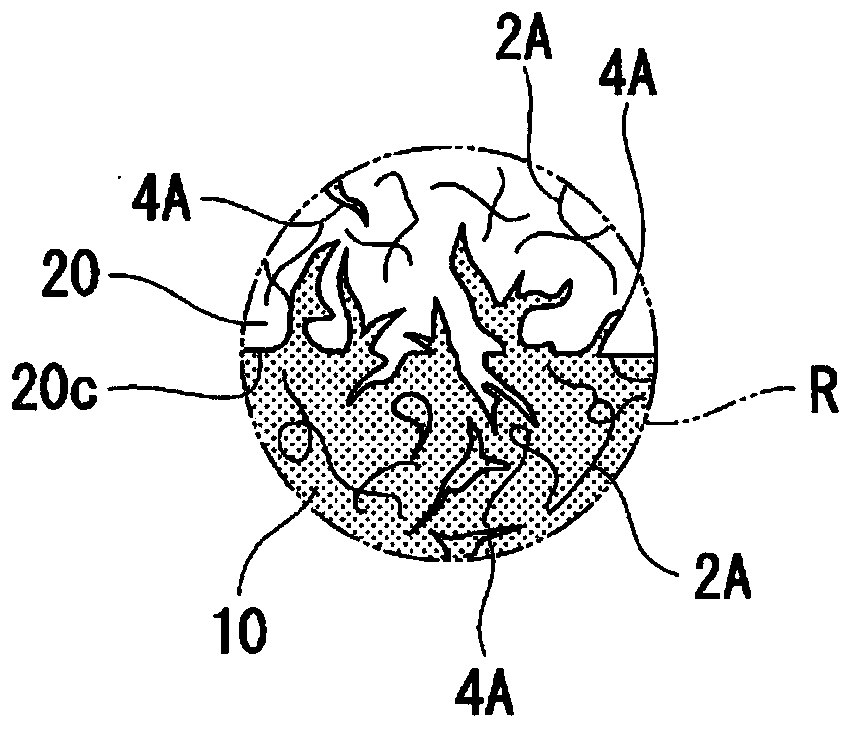

[0085] The buffer layer 51 includes: a thermal bonding layer 10 including a fibrous base material 2A and a bonding material 4A having a melting point lower than that of the base material 2A; a surface layer 20 bonded to a surface (one surface) 10a of the thermal bonding layer 10 It is composed of a base material 2A; and an intermediate layer 31 bonded to the back surface 10b of the thermally bonding layer 10 . The bonding material 4A is impregnated into the bonding surface 20 c of the surface layer 20 bonded to the thermal bonding layer 10 and t...

no. 2 approach

[0168] In the second embodiment, the same reference numerals are assigned to the same and similar components as those in the first embodiment, and detailed description thereof will be omitted.

[0169]

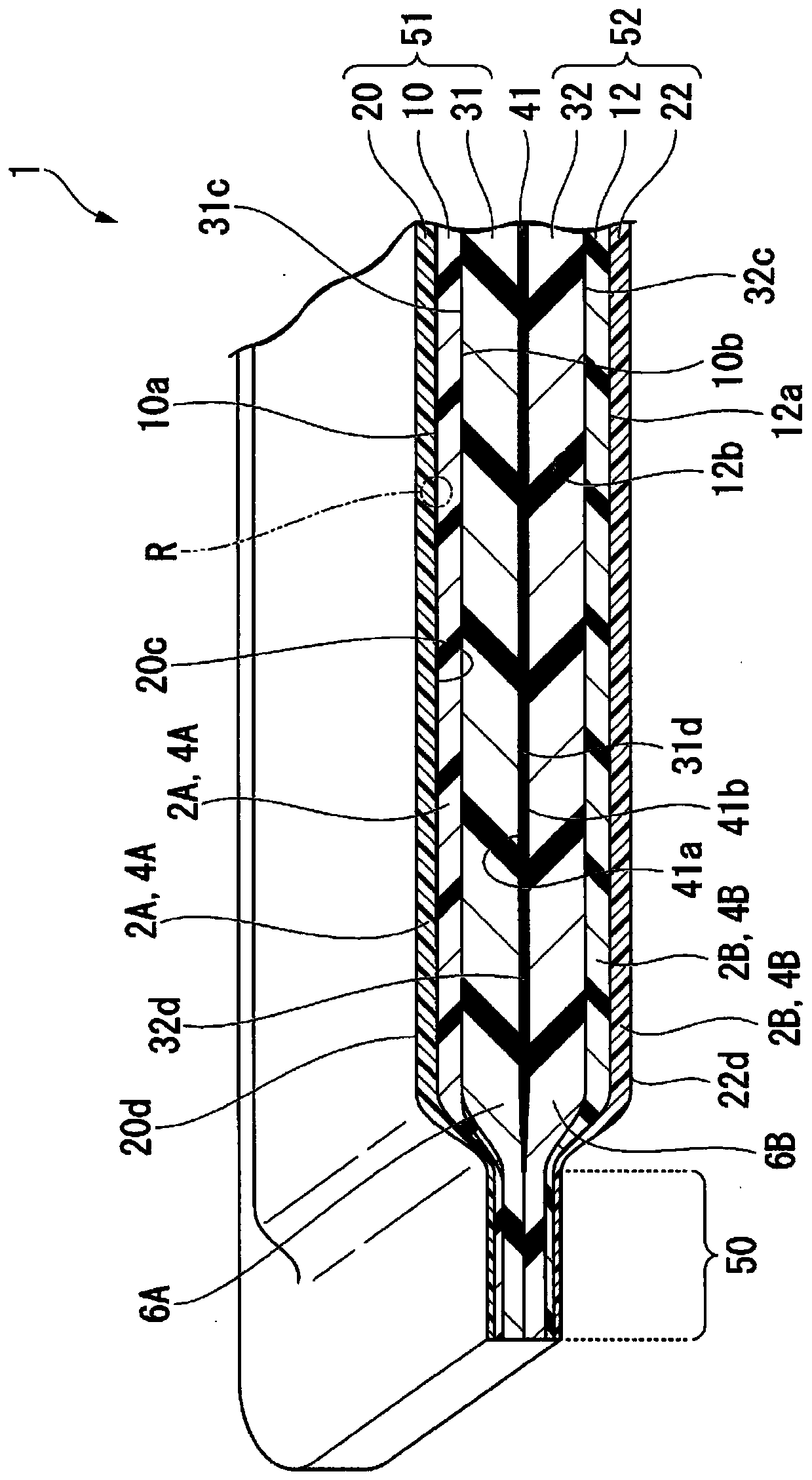

[0170] Such as Figure 8A , Figure 8B As shown, the panel body 1 of the second embodiment of the present invention is used to divide the space in the office space (not shown), and it includes: a buffer layer (laminate) 61 including a fibrous base material 2A, a buffer layer (laminate) body) 62, and the thermal bonding layer (first thermal bonding layer) 10 and thermal bonding layer (second thermal bonding layer) 12 disposed between these laminated bodies 61, 62, wherein the thermal bonding layer (first thermal bonding layer) The thermal bonding layer) 10 includes a fibrous base material 2A and a bonding material 4A having a melting point lower than that of the base material 2A; Low bonding material 4B. Surface layer 20 made of base material 2A is bonded to surface (one s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com