Method for enhancing properties of fish myofibrillar protein gel based on combination of catechin and polyphenol oxidase

A technology of myofibrillar protein and polyphenol oxidase, which is applied in fish protein components, animal protein processing, protein food ingredients, etc., can solve the problem of myofibrillar protein gel product quality, unstable sensory properties, and affecting products Quality product shelf life and other issues, to achieve the effect of facilitating industrial production, maintaining color and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

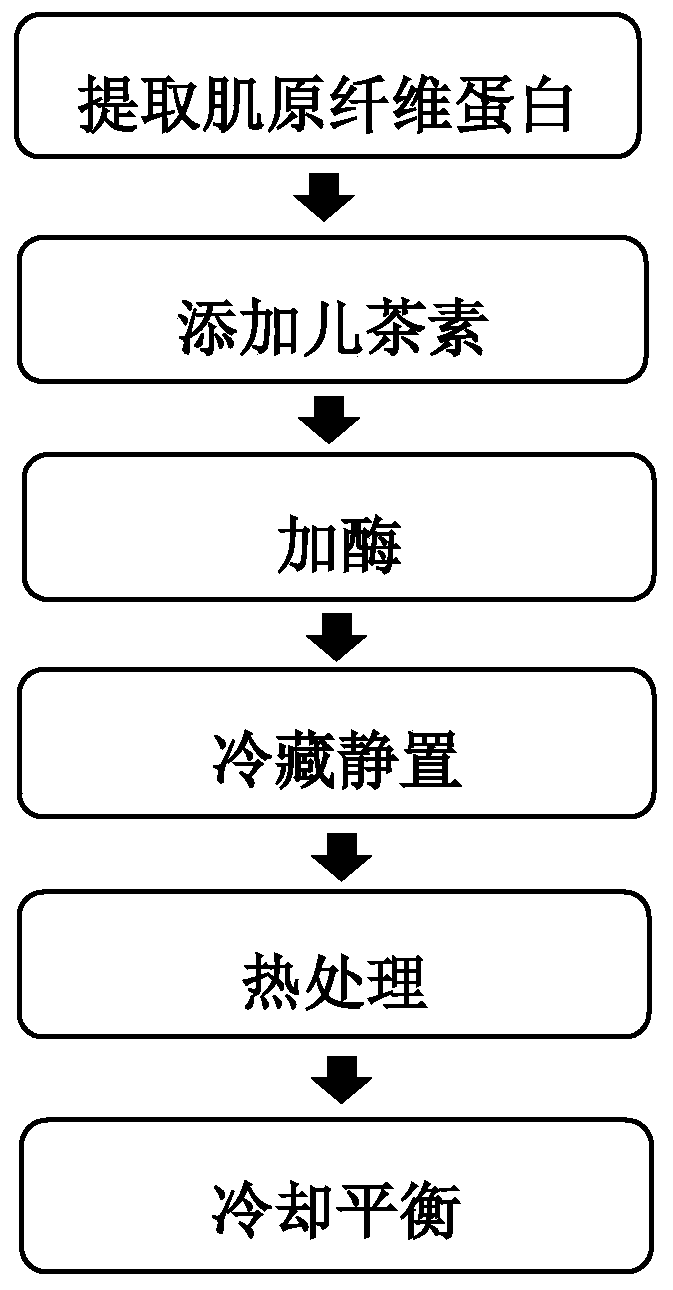

[0054] A method for enhancing the gel properties of tilapia myofibrillar protein based on the combination of catechin and polyphenol oxidase, comprising the steps of:

[0055] S1, extract myofibrillar protein: take tilapia meat, extract tilapia myofibrillar protein, prepare 35mg / ml tilapia myofibrillar protein solution;

[0056] S2. Mixing: take 8 g of the tilapia myofibrillar protein solution described in step S1 and add 0.375 ml of catechin solution with a concentration of 80 μmol / mL, and then homogenate and mix to obtain a mixture;

[0057] S3. Adding enzyme: adding polyphenol oxidase to the mixture described in step S2, and standing at 30°C for 1 hour to obtain mixture 2; the amount of polyphenol oxidase added is 1000U;

[0058] S4, refrigerating and standing: the mixture 2 described in step S3 was refrigerated and kept at 4°C for 14 hours, and then packaged to obtain a semi-finished product;

[0059] S5. Heat treatment: heat the semi-finished product described in step S4...

Embodiment 2

[0070] A method for enhancing the gel properties of tilapia myofibrillar protein based on the combination of catechin and polyphenol oxidase, comprising the steps of:

[0071] S1, extracting myofibrillar protein: take tilapia meat, extract tilapia myofibrillar protein, and prepare a solution of tilapia myofibrillar protein with a concentration of 45 mg / ml;

[0072] S2. Mixing: take 10 g of the tilapia myofibrillar protein solution described in step S1 and add 0.7 ml of catechin solution with a concentration of 100 μmol / mL, and then homogenate and mix to obtain a mixture;

[0073] S3. Adding enzyme: adding polyphenol oxidase to the mixture described in step S2, and standing at 35° C. for 2 hours to obtain mixture 2; the amount of polyphenol oxidase added is 3000 U;

[0074] S4, refrigerating and standing: the mixture 2 described in step S3 was refrigerated and kept at 4°C for 15 hours, and then packaged to obtain a semi-finished product;

[0075] S5. Heat treatment: heat the s...

Embodiment 3

[0086] A method for enhancing the gel properties of tilapia myofibrillar protein based on the combination of catechin and polyphenol oxidase, comprising the steps of:

[0087] S1, extracting myofibrillar protein: take tilapia meat, extract tilapia myofibrillar protein, and prepare a solution of tilapia myofibrillar protein with a concentration of 55 mg / ml;

[0088] S2. Mixing: Take 12 g of the tilapia myofibrillar protein solution described in step S1 and add 0.86 ml of catechin solution with a concentration of 150 μmol / mL, and then homogenate and mix to obtain a mixture;

[0089] S3. Adding enzyme: adding polyphenol oxidase to the mixture described in step S2, and standing at 40° C. for 3 hours to obtain mixture 2; the amount of polyphenol oxidase added is 5000 U;

[0090] S4, refrigerating and standing: the mixture 2 described in step S3 was refrigerated and kept at 4°C for 18 hours, and then packaged to obtain a semi-finished product;

[0091] S5. Heat treatment: heat the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com