Production process method of optical fiber Christmas tree

A production process and technology for Christmas trees, applied in the field of production technology of optical fiber Christmas trees, can solve the problems of lack of novelty and low aesthetics of the Christmas tree, and achieve the effects of novelty, enhanced festive atmosphere, and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

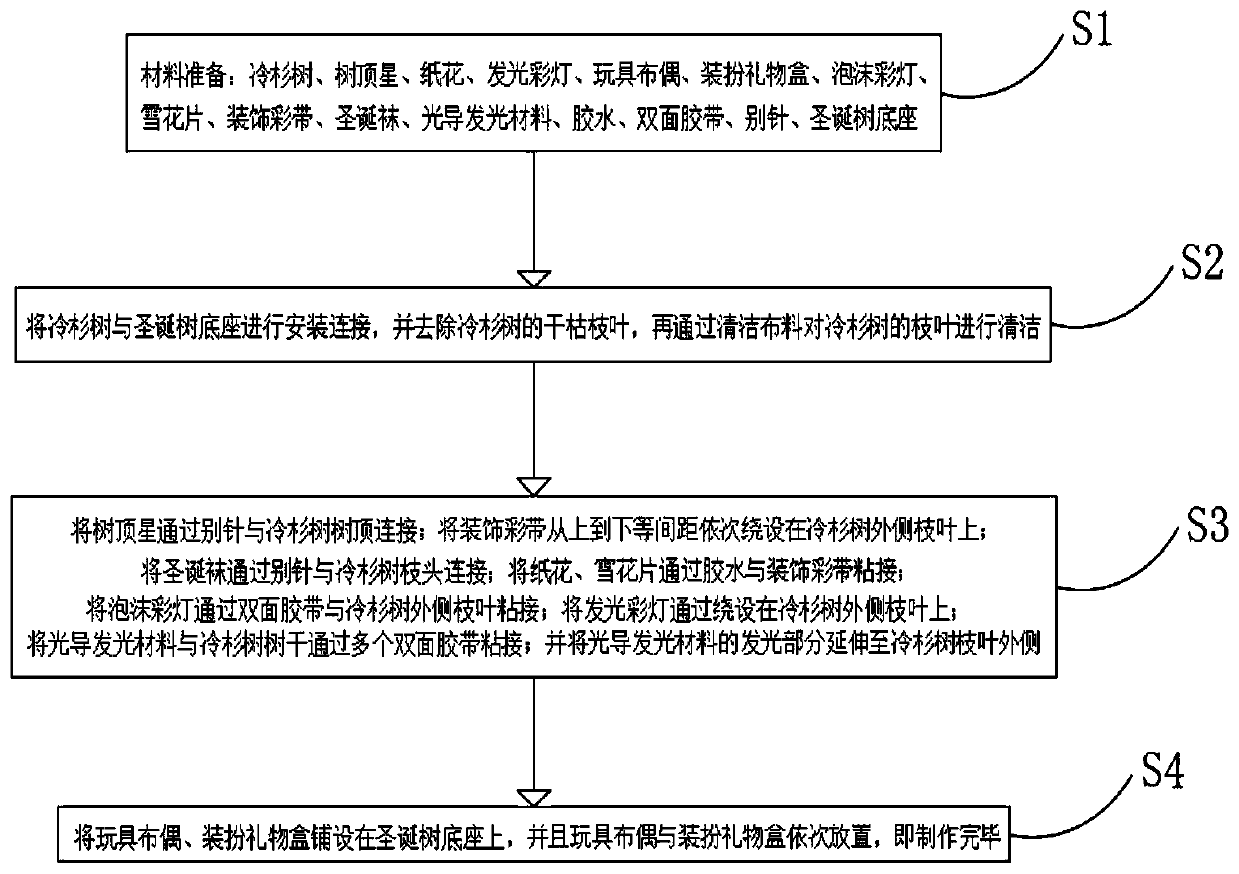

[0023] A production process method for an optical fiber Christmas tree, comprising the following steps:

[0024] S1: Prepare the following materials: 1.2m fir tree, 20 tree top stars, 10 paper flowers, 5 luminous lanterns, 4 toy puppets, 4 dress-up gift boxes, 10 foam lanterns, 20 snowflakes , 6 decorative ribbons, 7 Christmas stockings, 10 photoluminescent materials, glue, double-sided tape, pins, Christmas tree base, the color of the decorative ribbon is red; the snowflakes are made of acrylic material; the photoluminescent materials include multiple light guides Fiber filaments, light source box and LED diodes arranged inside the light source box; the colors of paper flowers include red, blue, yellow and pink; the colors of foam lanterns include red, yellow and green;

[0025] S2: Install and connect the fir tree to the base of the Christmas tree, remove the dry branches and leaves on the fir tree, and clean the branches and leaves on the fir tree with a cleaning cloth to a...

Embodiment 2

[0029] A production process method for an optical fiber Christmas tree, comprising the following steps:

[0030] S1: Prepare the following materials: 1.3m fir tree, 28 treetop stars, 15 paper flowers, 6 luminous lanterns, 5 toy puppets, 5 dress-up gift boxes, 11 foam lanterns, 24 snowflakes , 7 decorative ribbons, 9 Christmas stockings, 13 photoluminescent materials, glue, double-sided tape, pins, Christmas tree base, the color of the decorative ribbon is red; the snowflakes are made of acrylic material; the photoluminescent materials include multiple light guides Fiber filaments, light source box and LED diodes arranged inside the light source box; the colors of paper flowers include red, blue, yellow and pink; the colors of foam lanterns include red, yellow and green;

[0031] S2: Install and connect the fir tree to the base of the Christmas tree, remove the dry branches and leaves on the fir tree, and clean the branches and leaves on the fir tree with a cleaning cloth to av...

Embodiment 3

[0035] A production process method for an optical fiber Christmas tree, comprising the following steps:

[0036] S1: Prepare the following materials: 1.5m fir tree, 35 tree top stars, 20 paper flowers, 8 luminous lanterns, 7 toy puppets, 6 dress-up gift boxes, 13 foam lanterns, 26 snowflakes , 8 decorative ribbons, 12 Christmas stockings, 16 photoluminescent materials, glue, double-sided tape, pins, Christmas tree base, the color of the decorative ribbon is red; the snowflakes are made of acrylic material; the photoluminescent materials include multiple light guides Fiber filaments, light source box and LED diodes arranged inside the light source box; the colors of paper flowers include red, blue, yellow and pink; the colors of foam lanterns include red, yellow and green;

[0037] S2: Install and connect the fir tree to the base of the Christmas tree, remove the dry branches and leaves on the fir tree, and clean the branches and leaves on the fir tree with a cleaning cloth to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap